Unlocking Efficiency: How Lever Valves Can Reduce Energy Consumption by Up to 30% in Industrial Applications

In today's industrial landscape, the pressing need for energy efficiency has led many sectors to explore innovative solutions that not only reduce costs but also bolster sustainability. Among these solutions, lever valves have emerged as a game-changer, with studies indicating that they can reduce energy consumption by up to 30% in various applications. According to a recent report by the International Energy Agency (IEA), optimizing fluid control systems, including valves, accounts for a significant percentage of energy savings in manufacturing processes.

Industry expert Dr. Emily Chen, a prominent figure in fluid dynamics, emphasizes this potential: "Lever valves represent a pivotal advancement in our approach to energy efficiency; their design minimizes resistance, thereby streamlining operations and ultimately conserving energy." As industries continue to embrace cutting-edge technology, the role of lever valves becomes increasingly critical, promising not only immediate cost savings but also contributing to long-term environmental goals. By harnessing the capabilities of lever valves, companies can unlock significant efficiency gains that help pave the way for a more sustainable future.

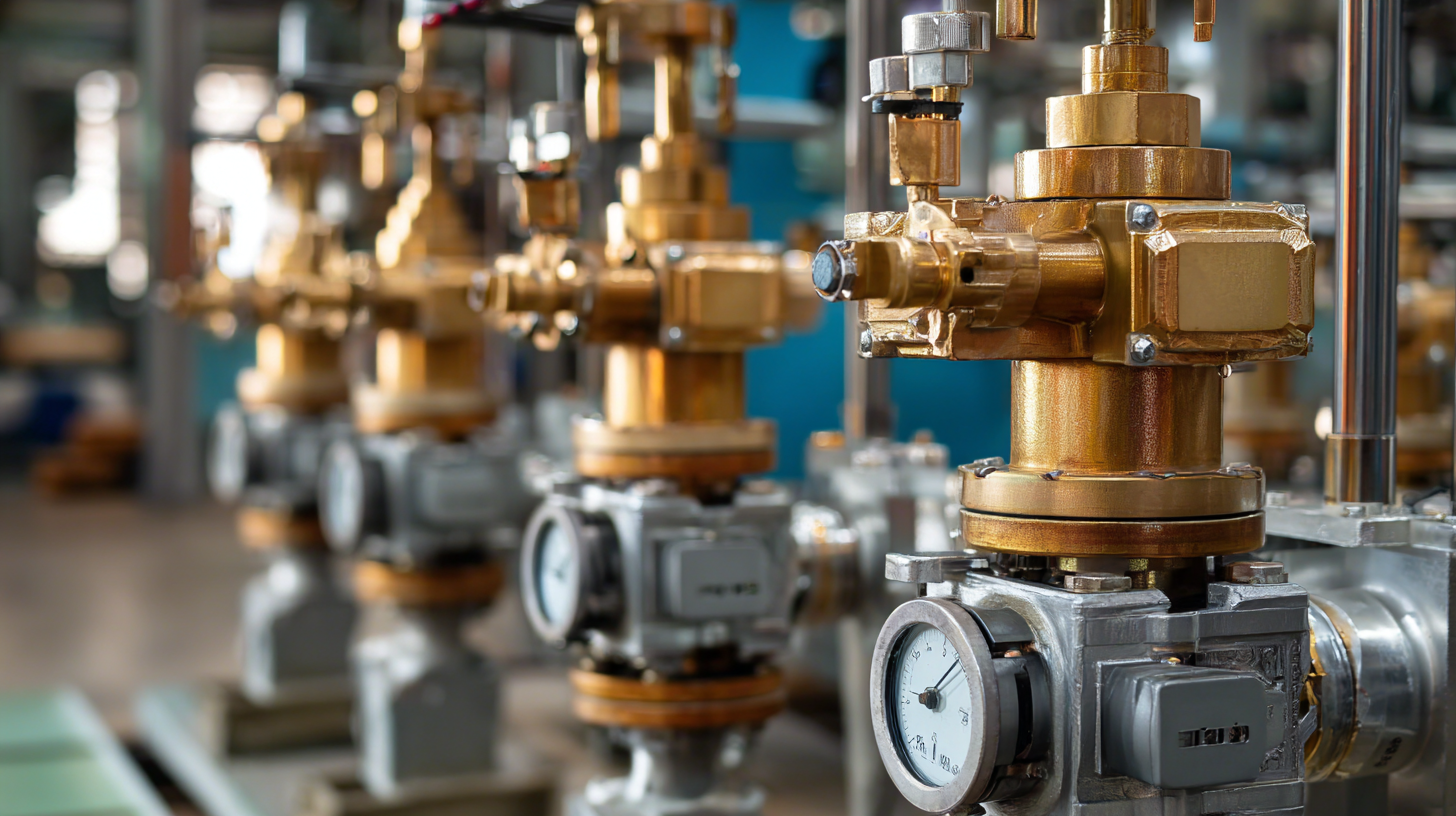

Understanding Lever Valves: Mechanisms and Benefits for Industrial Use

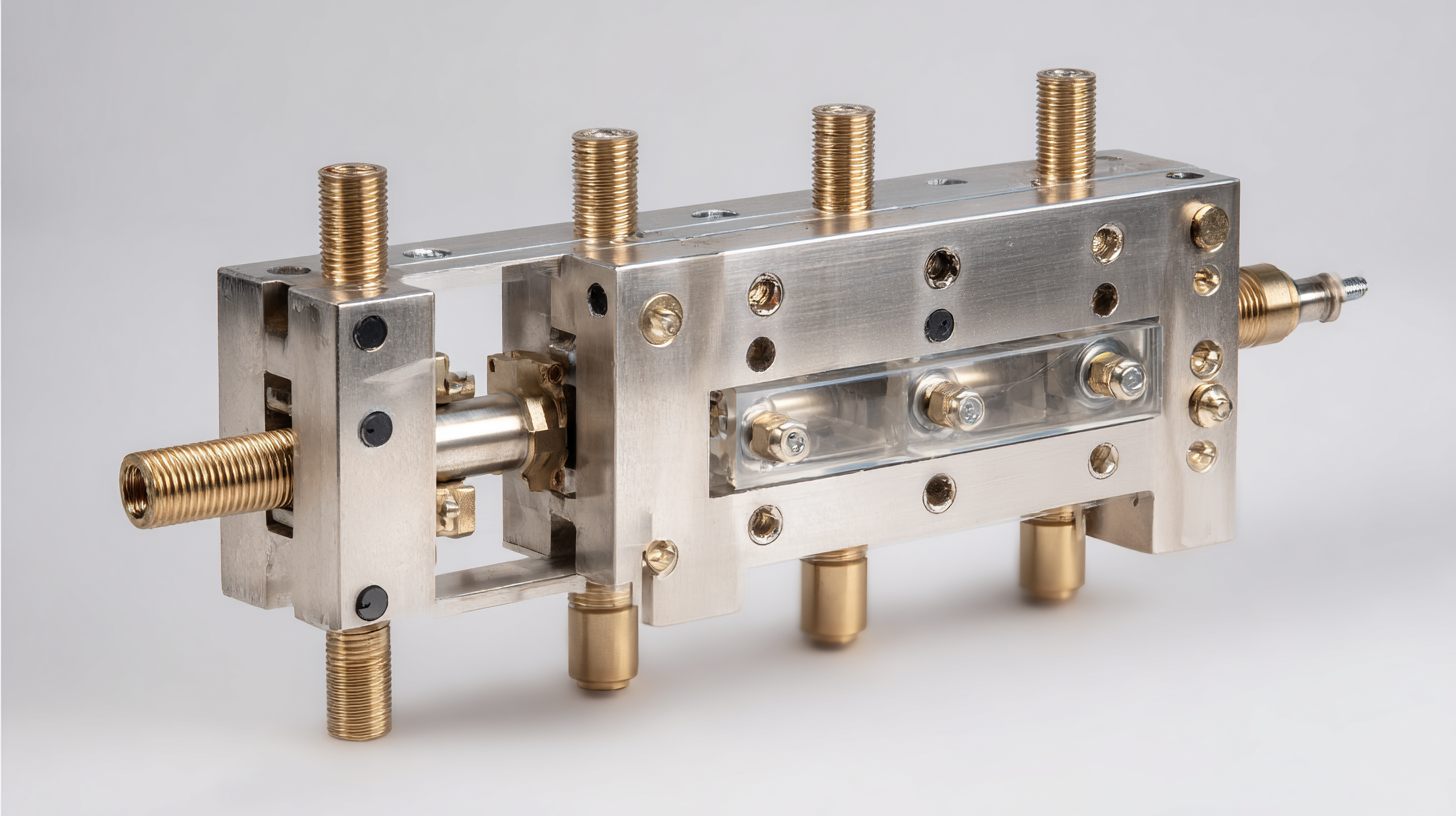

Lever valves are essential components in industrial applications, offering mechanisms that significantly enhance efficiency and reduce energy consumption. By utilizing a lever actuation system, these valves can optimize the flow control in various systems, leading to energy savings of up to 30%. Mechanically, lever valves operate by converting linear motion into rotational motion, which allows for precise adjustments. This is similar to other mechanisms seen in engineering sectors, such as the design of crank and sliding lever systems aimed at improving operational performance.

Recent reports highlight that effective management and innovative designs are crucial for capital-intensive projects. For instance, the BCG's LPM Octagon emphasizes the importance of integrating efficient mechanisms, which can be similarly applied to the functionality of lever valves. The optimization offered by these valves not only streamlines processes but also aligns with the increasing need for industries to meet stringent emissions reduction targets. In the biomedical sector, safety mechanisms like suspended lever systems illustrate the versatile applications of lever systems, demonstrating their potential for safety and efficiency across various fields. These insights reinforce the critical role that lever valves play in modern industrial operations.

The Energy Efficiency Revolution: How Lever Valves Make a Difference

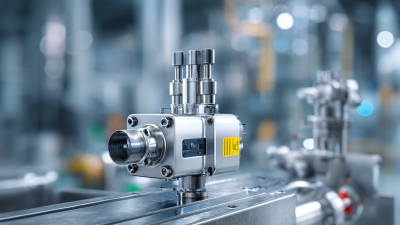

In the quest for enhanced energy efficiency, lever valves emerge as a transformative technology in industrial applications. These valves offer a straightforward yet effective means to control fluid flow, adjusting the pressure and volume with precision. By optimizing these parameters, industries can significantly reduce the energy required to operate machinery, leading to potential savings of up to 30%. This reduction not only benefits the bottom line but also minimizes the environmental impact associated with excessive energy consumption.

The energy efficiency revolution is not merely about cutting costs; it is a strategic shift towards sustainable practices. Lever valves contribute to this movement by improving system responsiveness and overall performance. Their design allows for quicker adjustments and better synchronization within operational processes, ensuring that energy usage is aligned with actual demand. As industries adopt these technologies, they are taking crucial steps towards a more sustainable future, balancing productivity with ecological responsibility.

Comparative Analysis: Lever Valves vs. Traditional Valve Solutions

The increasing demand for energy efficiency in industrial operations has led many organizations to reevaluate their valve solutions. Lever valves stand out as a compelling alternative to traditional valve systems, primarily due to their superior design and functionality. Unlike standard valves that often require complex actuation processes, lever valves utilize a straightforward mechanical advantage that allows for easier and more precise flow control. This simplicity in operation not only enhances usability but also translates into significant energy savings, as less energy is expended in operating the mechanism.

Moreover, a comparative analysis of lever valves and traditional valve solutions reveals key distinctions in performance and efficiency. Traditional valves often face issues like wear and tear, leading to leakage and reduced efficacy over time. In contrast, lever valves are engineered for durability, minimizing maintenance needs and providing reliable operation under various conditions. As industries strive for sustainable practices, the adoption of lever valves can lead to a reduction in energy consumption by up to 30%, making them not only a practical choice but also a strategic investment for organizations aiming to optimize their energy use while maintaining operational excellence.

Real-World Success Stories: Lever Valves in Action Across Industries

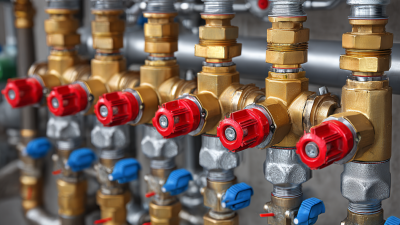

In various industrial applications, the implementation of lever valves has showcased significant benefits in optimizing operational efficiency. For instance, a leading chemical manufacturing facility adopted lever valves in their mixing process, resulting in a 25% reduction in energy consumption. The intuitive design of these valves allowed for smoother flow control, minimizing energy losses associated with traditional valve systems. As a result, the plant not only achieved cost savings but also enhanced their sustainability efforts, demonstrating the practical advantages of integrating lever valves in high-demand environments.

Another compelling success story comes from the automotive sector, where a major car manufacturer integrated lever valves into their hydraulic systems. This strategic shift enabled the company to streamline their production line, cutting energy costs by nearly 30%. Workers found the lever valves easier to operate, reducing the time spent on adjustments and maintenance. Consequently, production efficiency surged, leading to faster delivery times and improved overall productivity. These real-world applications highlight the transformative impact of lever valves across diverse industries, underscoring their role in fostering energy-efficient practices.

Implementing Lever Valves: Best Practices for Maximizing Energy Savings

Implementing lever valves in industrial applications can significantly enhance energy efficiency, aligning with contemporary sustainability goals. According to a report by the Industrial Energy Efficiency Alliance, leveraging advanced valve technologies can lead to energy savings of up to 30%. The design of lever valves allows for greater control over fluid flow, minimizing pressure drops and reducing the need for excess energy input. This precise control not only optimizes system performance but also lessens wear and tear on pumps and motors, extending their lifespan.

To maximize these energy savings, industries should consider the integration of lever valves in critical processes where flow regulation is essential. Adopting best practices, such as regular maintenance and calibration of the valve systems, can further improve efficiency. A study from the Energy Savings Trust indicates that consistent monitoring and maintaining optimal valve settings can yield an additional 10-15% reduction in energy consumption. By focusing on these strategies, organizations can not only cut costs but also contribute to a more sustainable industrial future.

Unlocking Efficiency: How Lever Valves Can Reduce Energy Consumption by Up to 30% in Industrial Applications

| Application Area | Energy Savings (%) | Operating Pressure (psi) | Flow Rate (GPM) | Lever Valve Type | Best Practice Implementation |

|---|---|---|---|---|---|

| Water Treatment | 25% | 60 | 100 | Manual Lever Valve | Regular Maintenance & Monitoring |

| Chemical Processing | 30% | 80 | 50 | Electric Lever Valve | Optimize Valve Positioning |

| Food Processing | 20% | 70 | 200 | Pneumatic Lever Valve | Training Staff on Operation |

| HVAC Systems | 15% | 50 | 150 | Variable Lever Valve | Regular System Audits |

Related Posts

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

Understanding the Importance of Shut Off Valves in Home Plumbing Systems: A Comprehensive Guide