Top 10 Gate Valves Types and Their Best Applications for Your Projects

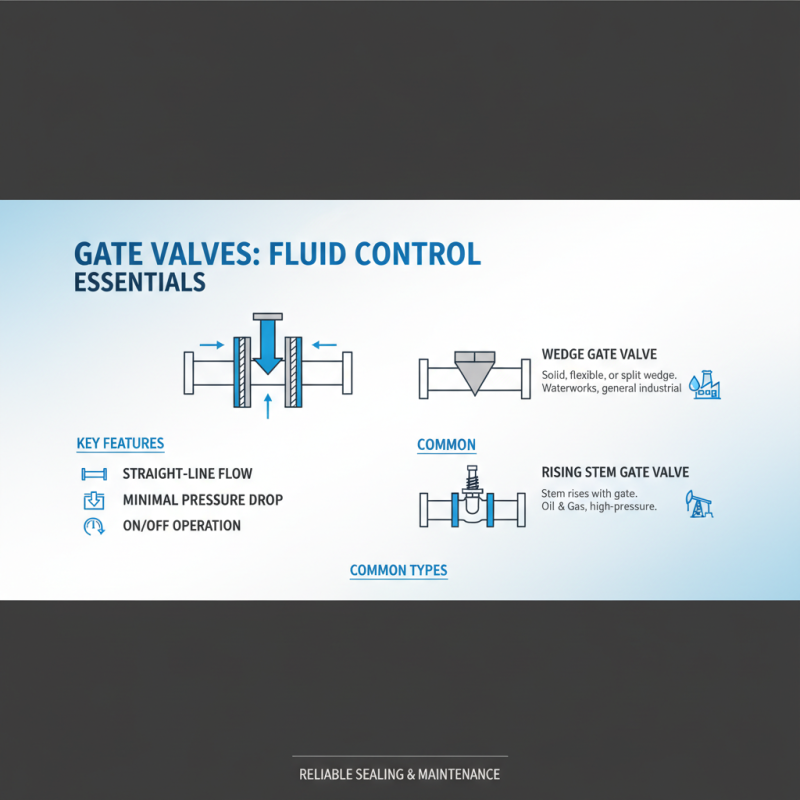

Gate valves are crucial components in piping systems, playing a vital role in controlling the flow of liquids and gases in various applications. Their design allows for minimal flow resistance when fully open, making them ideal for on/off services rather than throttling applications. In industrial, commercial, and residential infrastructure, selecting the right type of gate valve can significantly affect system efficiency and longevity. Understanding the different types of gate valves and their best applications enables engineers and project managers to make informed decisions tailored to their specific needs.

This article explores the top ten types of gate valves and highlights their optimal uses in a range of projects. From the robust wedge gate valves to the more specialized parallel gate valves, each type possesses unique characteristics that cater to diverse operational requirements. By examining factors such as pressure ratings, materials, and operational environments, this guide aims to equip professionals with the knowledge necessary to choose the most suitable gate valves for their systems. In doing so, it contributes to improved reliability and performance in fluid control applications.

Top 10 Gate Valve Types: An Overview of Design and Functionality

Gate valves are essential components in fluid control systems, designed to provide a straight-line flow path and minimal pressure drop. Their functionality primarily revolves around opening and closing the flow of liquids or gases effectively. There are several types of gate valves, each with unique designs catering to specific applications. For instance, wedge gate valves are commonly used in waterworks, while rising stem gate valves are preferred in oil and gas industries due to their reliable sealing capabilities and ease of maintenance.

According to industry reports, the global gate valve market is projected to grow significantly over the next few years, with estimates reaching USD 23 billion by 2026. This growth can be attributed to increasing infrastructure development and the need for efficient fluid control solutions. Engineers often consider factors like pressure ratings, temperature limits, and material durability when selecting gate valve types for their projects.

**Tips:** When specifying gate valves for industrial applications, always take into account the operating environment and the media being controlled. Selecting the appropriate gate valve type can enhance system performance and reduce maintenance costs. It's also vital to periodically review operational metrics to ensure the chosen gate valve continues to meet the evolving demands of the project.

Key Characteristics of Each Gate Valve Type: Materials and Standards

When selecting a gate valve for your projects, understanding the key characteristics of each type can significantly impact its performance and longevity. Gate valves are primarily designed to manage flow, and their construction materials typically include stainless steel, brass, and cast iron, each providing unique advantages. Stainless steel valves are highly resistant to corrosion, making them ideal for applications involving water and other fluids. Brass valves offer excellent machinability, while cast iron is known for its durability and strength, suitable for high-demand environments.

It's crucial to consider the applicable standards for gate valves, which vary by industry and use case. For instance, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) set guidelines that ensure safety and performance. Adhering to these standards not only guarantees compliance but also assures the reliability of your valve in critical applications.

Tip: Always match the gate valve material with the fluid it’ll control to prevent corrosion-related failures. Additionally, inspect the valve regularly to ensure that all components conform to required standards and are functioning correctly. Investing time in these considerations can save both time and costs in the long run.

Best Applications for Each Gate Valve: Industry Insights and Data

Gate valves are crucial components in various industries, with their best applications reflecting the specific needs of those sectors. According to the International Valve Association, approximately 40% of industrial valve usage is allocated to gate valves, primarily due to their ability to provide a tight seal and control the flow of liquids and gases. Their design allows for minimal pressure drop, making them ideal for applications requiring full flow and minimal turbulence. In oil and gas sectors, gate valves are often employed in upstream and downstream processes, where reliability and durability are key, given the high pressures and harsh environments involved.

In water treatment facilities, gate valves serve an essential function in regulating water flow and ensuring efficient distribution. A report by the Water Environment Federation (WEF) indicates that proper valve selection can reduce maintenance costs by up to 30% over the lifecycle of treatment plants. Additionally, gate valves' robust structure suits them for use in wastewater management, where they can withstand corrosive conditions while ensuring that part of the system remains operational during maintenance or failure incidents. Understanding the specific characteristics of the various gate valve types available allows engineers to make informed choices that enhance efficiency and safety in their projects.

Comparison of Gate Valves: Cost, Performance, and Maintenance Factors

When choosing the right gate valve for your project, understanding the cost, performance, and maintenance factors is crucial. According to industry reports, the initial purchase cost of gate valves can range from $50 to $1,500, depending on the material and size. While metal gate valves tend to be more expensive, they often provide superior durability and can withstand higher pressures and temperatures. In contrast, plastic variants are more cost-effective but might not be suitable for all high-stress applications. Properly evaluating these initial costs against the requirements of your project ensures an informed decision that aligns with your budget.

Performance is another essential consideration. Gate valves are renowned for their ability to provide a straight-line flow with minimal resistance, making them ideal for applications where full flow is necessary, such as in waterworks or petroleum pipelines. However, they do have limitations; for instance, they are not suitable for throttling, which can lead to increased wear. The American Society of Mechanical Engineers (ASME) recommends regular performance evaluations to gauge efficiency, helping project managers prioritize valves that best meet application demands.

**Tips:** Regular maintenance is key to extending the life of your gate valves. It’s advisable to implement a routine inspection schedule to monitor wear and tear, as well as to identify any leaks early on. Additionally, when installing gate valves, consider the potential operational environment, such as temperature fluctuations and media types, to select the most compatible materials and designs for longevity and efficiency.

Future Trends in Gate Valve Technology: Innovations and Market Projections

The landscape of gate valve technology is rapidly evolving, driven by advancements in materials science and automation. As industries increasingly prioritize efficiency and sustainability, innovations such as corrosion-resistant alloys and smart valve technology are becoming essential. These innovations not only improve reliability but also reduce maintenance costs and minimize downtime. According to a recent market report by Research and Markets, the global gate valve market is projected to grow at a CAGR of 3.5% from 2023 to 2030, reflecting a robust demand for advanced solutions in various sectors including oil and gas, water treatment, and power generation.

As gate valve technology progresses, we can expect more integration with IoT (Internet of Things) systems, allowing for remote monitoring and better operational control. Predictive maintenance will become a game-changer, with sensors embedded in valves providing real-time data that helps prevent failure before it occurs. Industry experts anticipate that this shift will enhance energy efficiency and operational safety significantly, which is crucial for meeting regulatory requirements and environmental standards.

Tips: When selecting gate valves for your projects, consider future-proofing your investment by opting for models that support smart technology integration. Additionally, always evaluate the materials used in valve construction to ensure they align with your project’s specific environmental conditions. Finally, staying informed about market projections can guide you in making strategic decisions that align with industry trends and demands.

Related Posts

-

10 Essential Tips for Locating and Operating Your Natural Gas Shut Off Valve

-

2025's Top 5 Flow Valve Innovations You Need to Know About

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

Top 10 Saunders Valves Benefits You Should Know