2025's Top 5 Flow Valve Innovations You Need to Know About

As the industrial landscape continues to evolve, the importance of flow valves in various applications cannot be understated. According to a report by MarketsandMarkets, the global flow valve market is projected to reach $11.2 billion by 2025, driven by the growing demand for precise fluid control in sectors such as oil and gas, water management, and chemical processing. With this substantial growth on the horizon, staying informed about the latest innovations in flow valve technology is essential for industry professionals.

In a recent interview, renowned valve expert Dr. Emily Carter emphasized the critical role of innovative designs in enhancing operational efficiency. She stated, “The future of flow valves lies in smart technology that not only optimizes performance but also integrates seamlessly with existing systems.” This perspective highlights the necessity for engineers and decision-makers to familiarize themselves with the cutting-edge flow valve solutions that will redefine performance standards in the coming years.

As we delve into the top five flow valve innovations expected to dominate in 2025, it’s vital to recognize the transformative impact these advancements will have on various industries. From enhanced materials to automation, understanding these trends will empower organizations to adapt and thrive in a rapidly changing marketplace.

The Rise of Smart Flow Valve Technology in 2025

Smart flow valve technology is set to revolutionize the industrial landscape in 2025. With the increasing demand for efficiency and precision in fluid management, these innovative valves are now equipped with advanced sensors and IoT capabilities. This integration allows for real-time monitoring and data analytics, enabling facilities to optimize their operations and reduce wastage. The ability to collect and analyze data from the flow valves facilitates predictive maintenance, minimizing downtime and enhancing overall performance.

Moreover, the rise of artificial intelligence in smart flow valves is paving the way for more adaptive and responsive systems. These valves can learn and adjust to varying flow conditions and system requirements, leading to improved process control. As industries strive for sustainability, this technology plays a crucial role in minimizing energy consumption, thereby supporting greener initiatives. With these advancements, smart flow valves are not just a component of fluid systems; they are becoming essential instruments for the future of smart manufacturing and industrial automation.

2025's Top 5 Flow Valve Innovations You Need to Know About - The Rise of Smart Flow Valve Technology in 2025

| Innovation | Description | Key Features | Applications | Expected Impact |

|---|---|---|---|---|

| AI-Driven Predictive Maintenance | Utilizes AI algorithms to predict maintenance needs before failures occur. | Real-time monitoring, data analysis, automatic alerts. | Oil and gas, water treatment, manufacturing | Reduced downtime and maintenance costs. |

| IoT-Enabled Flow Monitoring | Integration of IoT sensors for real-time flow monitoring and control. | Remote access, data visualization, automated adjustments. | Food processing, pharmaceuticals, chemicals | Enhanced efficiency and operational transparency. |

| Smart Valve Actuators | Electromechanical actuators with built-in intelligence for improved responsiveness. | High accuracy, quick response times, self-diagnostics. | Energy generation, HVAC systems, water supply | Improved control and energy efficiency. |

| Wireless Flow Control Systems | Wireless technology to control valve operations from remote locations. | Ease of installation, flexibility, reduced wiring costs. | Agriculture, irrigation, municipal water systems | Greater flexibility in operations management. |

| Flow Simulation Software | Advanced software for simulating fluid dynamics in different environments. | 3D modeling, scenario analysis, optimization tools. | Engineering, research and development, process optimization | Improved design and operation of flow systems. |

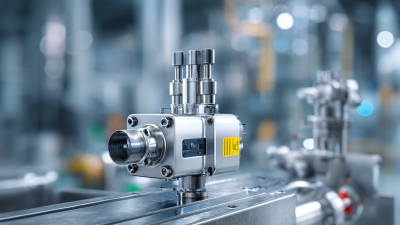

Key Features of Next-Generation Flow Valves You Should Consider

As the industry moves towards more advanced solutions, next-generation flow valves are being designed with key features that enhance both efficiency and functionality. One major innovation is the integration of smart technology, allowing valves to be monitored and controlled remotely. This capability not only improves system efficiency but also facilitates

predictive maintenance, minimizing downtime and reducing operational costs.

Another vital feature is the development of materials that withstand extreme conditions, such as high temperatures and corrosive environments. These new materials ensure longevity and reliability, making flow valves suitable for various applications, including chemical processing and oil and gas industries. Additionally, energy efficiency has become a crucial consideration, with many designs incorporating mechanisms that reduce energy consumption during operation, contributing to more sustainable practices in industrial processes.

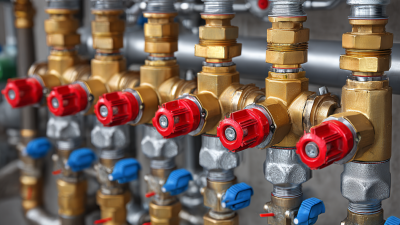

Comparative Analysis: Traditional vs. Innovative Flow Valve Designs

When examining flow valve innovations in 2025, it’s essential to understand the differences between traditional and innovative designs. Traditional flow valves, typically made from metal components, offer reliability but often fall short in energy efficiency and controlling flow precision. They can be cumbersome and require regular maintenance due to wear and tear on mechanical parts. In contrast, innovative flow valve designs leverage advanced materials such as polymers and composite materials, which significantly reduce weight and improve resistance to corrosion.

Tips: When selecting a flow valve, consider the application environment. In corrosive settings, opt for innovative materials that offer better longevity and less maintenance. Additionally, look for valves that incorporate smart technology, enabling real-time monitoring and adjustments to flow rate, thus optimizing energy usage.

Furthermore, the advancement in designs, including automated and smart flow control features, allows for more precise modulation of flow rates. This not only enhances process efficiency but also reduces waste. Embracing these innovations can lead to substantial cost savings and improved operational performance in various industries, from manufacturing to water treatment.

Tips: Stay updated on the latest technologies before making purchasing decisions, as many manufacturers are rapidly moving towards digital integration in their products. Always ensure compatibility with existing systems to maximize the benefits of new valve technologies.

Essential Maintenance Tips for the Latest Flow Valve Models

In the ever-evolving landscape of flow valve technology, staying informed about the latest innovations is crucial for optimizing performance and ensuring longevity. With the projected growth of the global flow valve market, anticipated to reach $20 billion by 2025 according to a recent report by Grand View Research, understanding essential maintenance practices becomes indispensable. Proper maintenance not only enhances functionality but also prevents costly downtime, which is estimated to account for 20-30% of operational expenses in industrial settings.

Tips for Maintenance:

- Regularly inspect seals and gaskets for wear and tear to prevent leaks, as up to 25% of industrial valve failures are attributed to seal degradation.

- Clean valves periodically to eliminate buildup, which can impede flow performance significantly, with data showing that a mere 1% buildup can reduce flow efficiency by up to 10%.

- Implement a proactive approach by scheduling routine check-ups based on the manufacturer's recommendations, as these can extend the lifespan of the valve significantly, sometimes doubling its operational life.

With the introduction of smart flow valve systems featuring IoT capabilities, technicians can now monitor performance in real-time, leading to more responsive maintenance strategies. The integration of predictive analytics not only enhances decision-making processes but significantly reduces the risk of unexpected failures. Keeping abreast of these advancements ensures that industries can leverage the full potential of their flow valve systems efficiently.

How Flow Valve Innovations Are Shaping Industrial Automation

In the realm of industrial automation, flow valve innovations are playing a pivotal role in enhancing efficiency and precision. As industries continue to adopt smarter technologies, the evolution of flow valves is at the forefront. These innovations are not only increasing the reliability of fluid management systems but also integrating seamlessly with cutting-edge automation platforms. This integration allows for real-time monitoring and control, transforming how facilities manage their resources and processes.

Tip: When selecting flow valves for your automation system, consider choosing those that offer advanced connectivity options. This will facilitate better data tracking and analysis, thereby optimizing system performance.

Moreover, the advent of smart flow valves equipped with IoT capabilities is revolutionizing predictive maintenance strategies. By leveraging data analytics, these valves can provide insights into their operational status, enabling timely interventions before issues escalate. This shift towards proactive maintenance not only minimizes downtime but also leads to significant cost savings.

Tip: To maximize the benefits of smart flow valves, ensure your team is trained on the latest data analysis tools and technologies. A skilled workforce can leverage these innovations to drive continuous improvement in your operations.

Related Posts

-

Best Home Valves for Energy Efficiency in 2023 Based on Industry Data

-

How to Choose the Right Lever Valve for Optimal Fluid Control in Industrial Applications

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

Understanding the Importance of Shut Off Valves in Home Plumbing Systems: A Comprehensive Guide

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide