2026 Top Butterfly Valves for Optimal Performance and Efficiency?

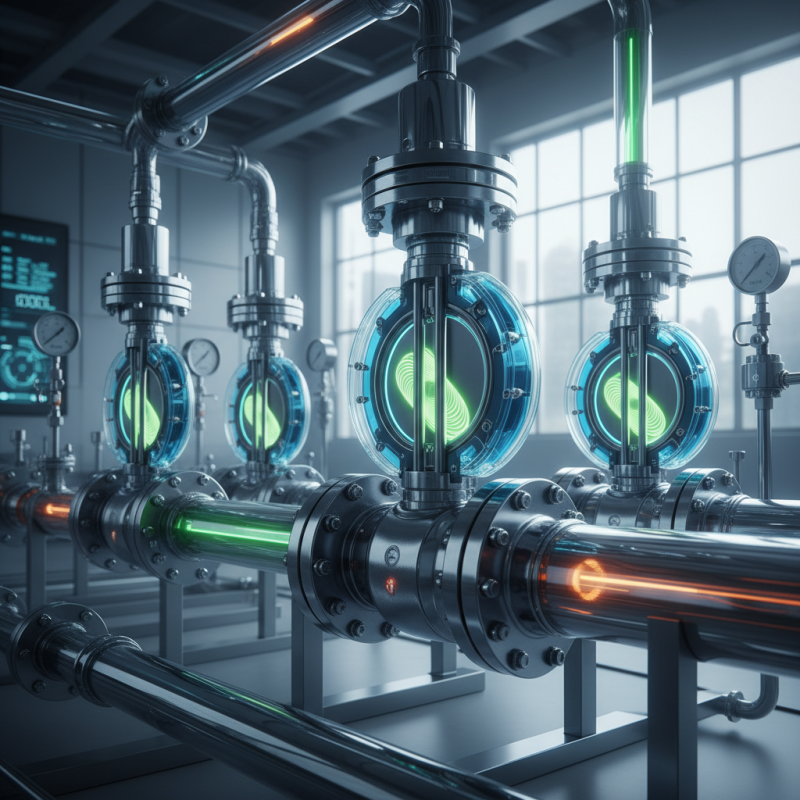

In the realm of fluid control technologies, butterfly valves play a pivotal role. These valves are known for their versatility and compact design. According to industry expert John Smith, "The efficiency of butterfly valves significantly impacts system performance." This insight highlights their importance in various applications.

When choosing the right butterfly valves, performance and efficiency are crucial factors. Selecting the wrong type can lead to leaks and energy loss. Optimize your choices by considering materials and design specifics. A well-chosen valve can enhance flow control significantly, while a poor selection may result in frequent maintenance and increased costs.

The future landscape of butterfly valves is evolving rapidly. Innovations are reshaping how these devices operate. However, not all developments are perfect; some may introduce new challenges. It’s essential to evaluate these advancements critically. As the industry progresses, understanding the finer details will ensure optimal performance and efficiency in applications.

Top Features of Butterfly Valves for Peak Performance

Butterfly valves are crucial for efficient system performance. Their design enables quick and effective flow control. Key features worth noting include size and materials. A good valve balances strength and weight. Choosing the wrong material can lead to frequent replacements.

Incorporating actuators can enhance functionality. Manual options are common, but automated versions offer better precision. Make sure they fit your system's requirements. Many users overlook the importance of proper sealing. A reliable seal prevents leaks, saving energy and costs in the long run.

Tip: Always check compatibility with existing systems. Misalignment often leads to inefficiencies. Regular maintenance is essential for peak performance. Ignoring small issues can result in larger, costly failures. Keep an eye on wear and tear.

2026 Top Butterfly Valves for Optimal Performance and Efficiency

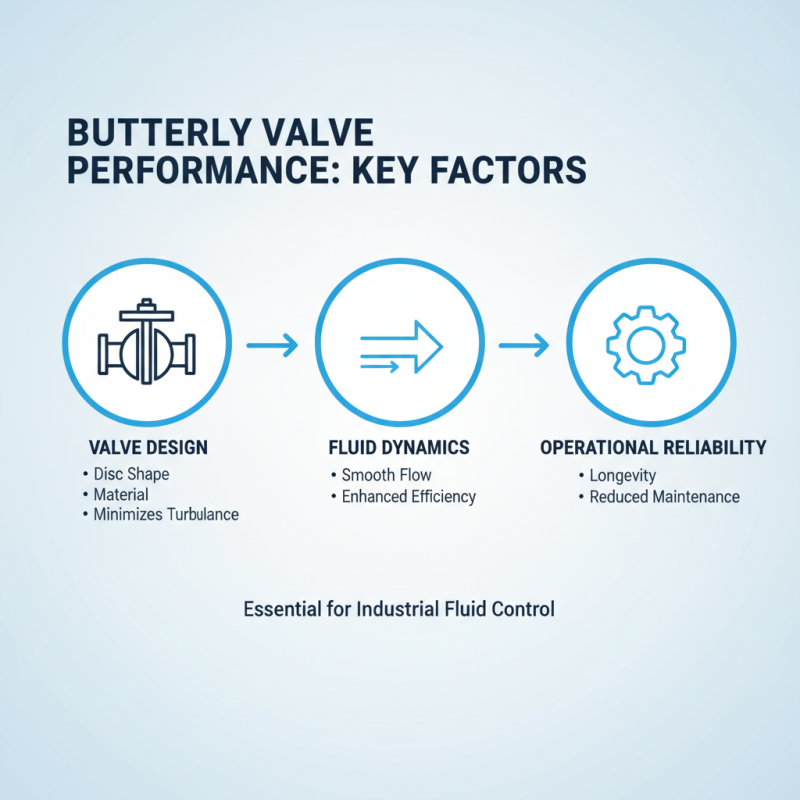

Factors Influencing the Efficiency of Butterfly Valves

Butterfly valves are essential in many industries for fluid control. Their performance relies heavily on several key factors. One significant element is the valve design, which includes disc shape and material. A well-designed valve minimizes turbulence and ensures smooth flow, enhancing efficiency.

Another factor is the actuator type. Electric or pneumatic actuators can influence response time and precision. Careful selection impacts overall performance. Proper installation is crucial too. Misaligned valves can lead to leaks and increased wear. Regular maintenance checks are necessary to catch these issues early.

Additionally, consider the fluid characteristics. Different fluids require different materials for optimal performance. Corrosive substances can wear down valves quickly. Finally, system pressure and temperature should be within the valve specifications. Consistency in these parameters can significantly improve lifespan and efficiency.

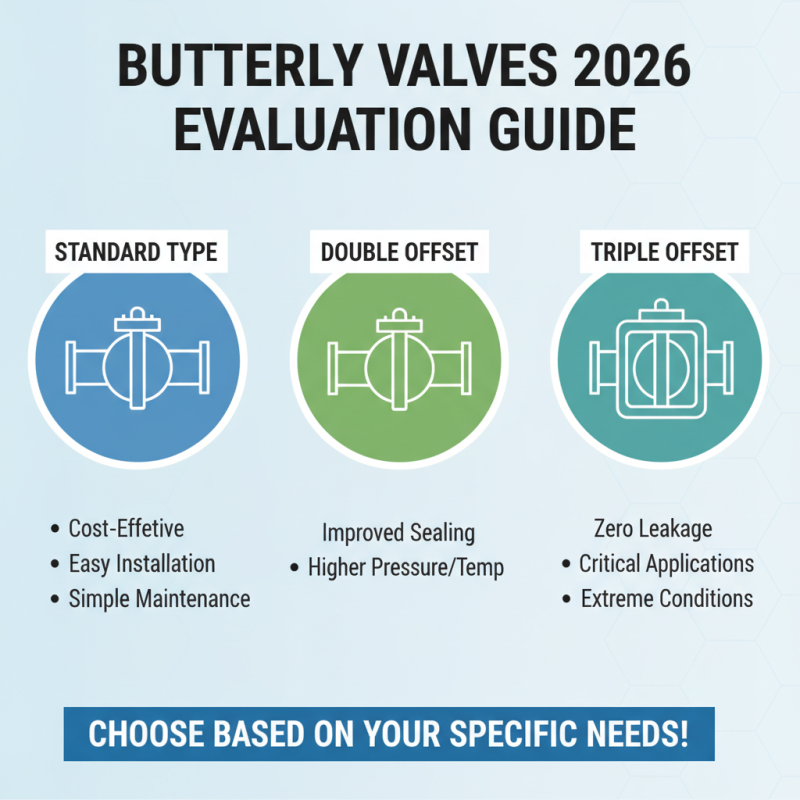

Comparison of Different Types of Butterfly Valves in 2026

When evaluating butterfly valves in 2026, various types offer different advantages. Standard butterfly valves are often cost-effective. They are easy to install and maintain, making them a leading choice in many industries. Nonetheless, users should consider their specific needs carefully.

In contrast, high-performance butterfly valves provide enhanced fluid control. These components are crucial in applications requiring precise regulation. Their design often allows for reduced pressure loss, improving overall efficiency. However, they can be more complex and expensive. Users must weigh these factors before making a decision.

Tips: Always assess the materials used in valve construction. They impact durability and performance. Regular maintenance is essential for optimal functioning. Don't overlook minor issues that could become significant problems. Lastly, understand the system dynamics where the valve will operate to make an informed choice.

Leading Brands and Models of Butterfly Valves This Year

When selecting the best butterfly valves for 2026, performance matters. These valves help control flow in various systems. Their design impacts efficiency significantly. Some models focus on lower pressure drops, allowing seamless flow. This feature is essential for energy savings.

Leading brands prioritize innovation in their butterfly valve designs. They emphasize materials that resist corrosion, enhancing longevity. Some models optimize sealing mechanisms for better performance. However, not all options work well in every application. Users need to understand specific requirements.

Installation can be tricky, often requiring professional help. Regular maintenance is vital to ensure optimal function. Some users overlook issues until they become major problems. This oversight can lead to efficiency losses. Being proactive in maintenance is necessary for best results.

Maintenance Tips for Ensuring Optimal Butterfly Valve Performance

Butterfly valves are crucial for many industrial applications. To ensure they work efficiently, regular maintenance is vital. Start by inspecting the valve regularly. Look for signs of wear or damage. Seals, in particular, are prone to leaks. Replacing them can prevent failures and inefficiencies.

Lubrication is also important. Apply lubricant to the stem and shaft. This reduces friction and helps the valve open and close smoothly. However, over-lubrication can attract dirt. Clean the areas around the valve as needed.

Pay attention to the actuator. It should operate without excessive force. If it struggles, check for blockages or misalignments. Ignoring these issues can lead to rapid deterioration. Lastly, keep records of maintenance work. Tracking repairs helps identify patterns. This can be critical in preventing future problems.

2026 Top Butterfly Valves for Optimal Performance and Efficiency

| Valve Type | Size (Inches) | Material | Pressure Rating (PSI) | Typical Applications |

|---|---|---|---|---|

| Standard Butterfly Valve | 1.5 | Cast Iron | 150 | Water Treatment |

| High Performance Butterfly Valve | 3 | Stainless Steel | 300 | Chemical Process |

| Plastic Butterfly Valve | 2 | PVC | 150 | Wastewater Management |

| Electric Butterfly Valve | 4 | Aluminum | 200 | HVAC Systems |

| Wafer Butterfly Valve | 6 | Ductile Iron | 250 | Pipelines |

Related Posts

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

Top Butterfly Valves Applications and Benefits Explained

-

What is a Gas Shut Off Valve and How Does It Work?

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

2026 Best Valve Products for Efficiency and Performance Review?

-

Top 5 Home Valve Solutions to Improve Your Plumbing Efficiency