Top Ball Valve Manufacturers to Watch in 2025 for Your Industry Needs

As industries continue to evolve and demand for advanced solutions grows, the role of ball valve manufacturers is becoming increasingly critical. According to a recent report by Grand View Research, the global ball valve market is projected to reach USD 16.25 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.2%. This surge is driven by various sectors, including oil and gas, water and wastewater management, and power generation, which all necessitate reliable and efficient flow control systems.

Experts in the field are highlighting the importance of innovation and quality in meeting these demands. Dr. Emily Roberts, a renowned authority on valve technology, stated, “The future of ball valve manufacturers hinges on their ability to adapt to changing market needs and invest in technological advancements.” As we move towards 2025, keeping an eye on leading manufacturers within this sector is essential for businesses aiming to enhance their operational efficiency and compliance with industry standards. Identifying key players who prioritize quality and innovation will be crucial for organizations seeking reliable partners in their endeavors.

Key Criteria for Selecting Top Ball Valve Manufacturers

When selecting the top ball valve manufacturers for your industry needs, it’s essential to consider several key criteria that can significantly impact your operational efficiency and project success. Firstly, evaluate the manufacturer’s experience and expertise in the specific applications relevant to your industry. A proven track record in producing durable and reliable ball valves tailored for particular environments or pressures is crucial. Additionally, look into the manufacturer's research and development capabilities; innovation in design and technology can enhance performance and extend product life.

Quality assurance is another vital criterion. Manufacturers should adhere to globally recognized standards for materials and production processes to ensure that their ball valves can withstand rigorous operational demands. It is advisable to review certifications, testing procedures, and customer feedback to gauge product reliability. Furthermore, consider the level of customer support and after-sales service provided by the manufacturer. Timely technical assistance and efficient response to inquiries can make a significant difference in minimizing downtime and maintaining system integrity.

Emerging Trends in the Ball Valve Industry by 2025

As we look towards 2025, the ball valve industry is poised to undergo significant transformations driven by technological advancements and evolving market demands. One of the most notable trends is the increasing integration of smart technologies into ball valve systems. According to a recent report by ResearchAndMarkets, the global market for smart valves is expected to grow at a CAGR of 10.5% from 2023 to 2028. This surge is indicative of a shift towards automation in industries such as oil and gas, water treatment, and chemical processing, where precise control and monitoring capabilities are paramount.

Additionally, environmental sustainability is becoming a central focus in the ball valve manufacturing sector. Manufacturers are increasingly adopting materials and processes that minimize environmental impact. A study by Grand View Research highlights that the green valve market is projected to account for over 25% of the overall ball valve market share by 2025, as companies strive to meet stringent regulations and consumer demands for eco-friendly products. This trend is not only vital for compliance but also enhances the brand image and competitive edge of manufacturers who embrace sustainable practices.

Furthermore, the demand for lightweight, durable materials is expected to rise, driven by the need for efficiency and ease of installation. The shift towards composite and plastic ball valves, as noted in multiple industry forecasts, will cater to sectors requiring corrosion resistance and reduced weight, further reshaping the landscape of the ball valve industry. As these trends unfold, stakeholders must stay informed and adaptable to leverage emerging opportunities in this evolving market.

Top Ball Valve Manufacturers to Watch in 2025 for Your Industry Needs - Emerging Trends in the Ball Valve Industry by 2025

| Manufacturer Type | Market Share (%) | Key Innovations | Projected Growth (2025) |

|---|---|---|---|

| Commercial Valves | 30% | Smart Monitoring Technology | 15% |

| Industrial Valves | 25% | Durable Materials | 12% |

| Specialty Valves | 20% | Corrosion Resistance | 10% |

| Fire-safe Valves | 15% | Enhanced Safety Features | 8% |

Profiles of Leading Ball Valve Manufacturers to Watch

As the demand for high-performance industrial components continues to grow, the spotlight falls on ball valve manufacturers that stand out in the market. These companies demonstrate innovation, reliability, and excellence in design and manufacturing. Key attributes to consider when evaluating these manufacturers include their commitment to quality control, advancements in technology, and a strong track record in customer service. Moreover, many are now focusing on sustainable practices, integrating eco-friendly materials and processes without compromising on performance.

When selecting a ball valve manufacturer, it's important to look for those that offer comprehensive support services. This could include detailed product documentation, responsive customer service teams, and effective supply chain management. Additionally, staying informed about industry trends and emerging technologies can provide valuable insights into which companies are likely to lead the market in the coming years.

**Tips for Choosing the Right Manufacturer:**

1. Assess their industry certifications and standards compliance to ensure the reliability of their products.

2. Research customer reviews and case studies to gauge the manufacturer's performance in real-world applications.

3. Consider manufacturers that offer customization options to meet your specific project needs, as this can greatly enhance efficiency and effectiveness in your operations.

Top Ball Valve Manufacturers to Watch in 2025

Innovative Technologies in Ball Valve Production

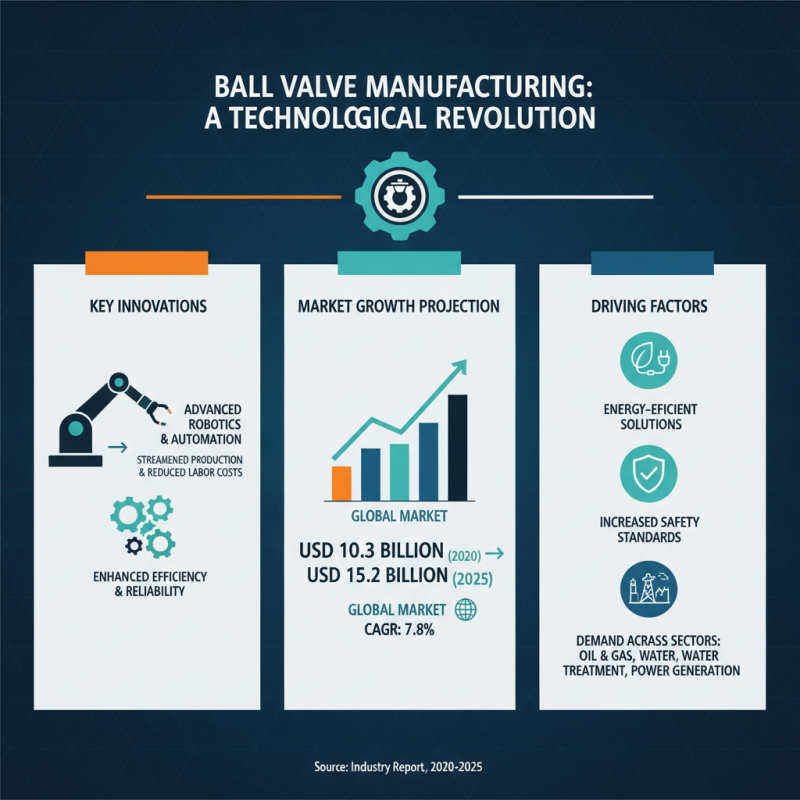

The ball valve manufacturing industry is witnessing a technological revolution that promises to enhance efficiency and reliability. Innovations such as advanced robotics and automation in production lines are streamlining processes and significantly reducing labor costs. According to a recent industry report, the global ball valve market is projected to grow from USD 10.3 billion in 2020 to USD 15.2 billion by 2025, indicating a compound annual growth rate (CAGR) of 7.8%. This growth can largely be attributed to the rising demand for energy-efficient and safe valve solutions across various sectors, including oil and gas, water treatment, and power generation.

Moreover, the incorporation of smart technologies, such as the Internet of Things (IoT), in ball valve production is setting a new standard for operational efficiency. Smart valves can provide real-time data analytics, enabling predictive maintenance and minimizing downtime. A study revealed that facilities utilizing IoT-enabled components can reduce operational costs by up to 30%, affirming the competitive advantage of leveraging such innovations. As manufacturers adapt to these trends, we can expect a more robust and technologically advanced offering in ball valve solutions tailored to meet the growing demand for sustainable industrial practices.

Market Growth and Opportunities for Ball Valve Suppliers in 2025

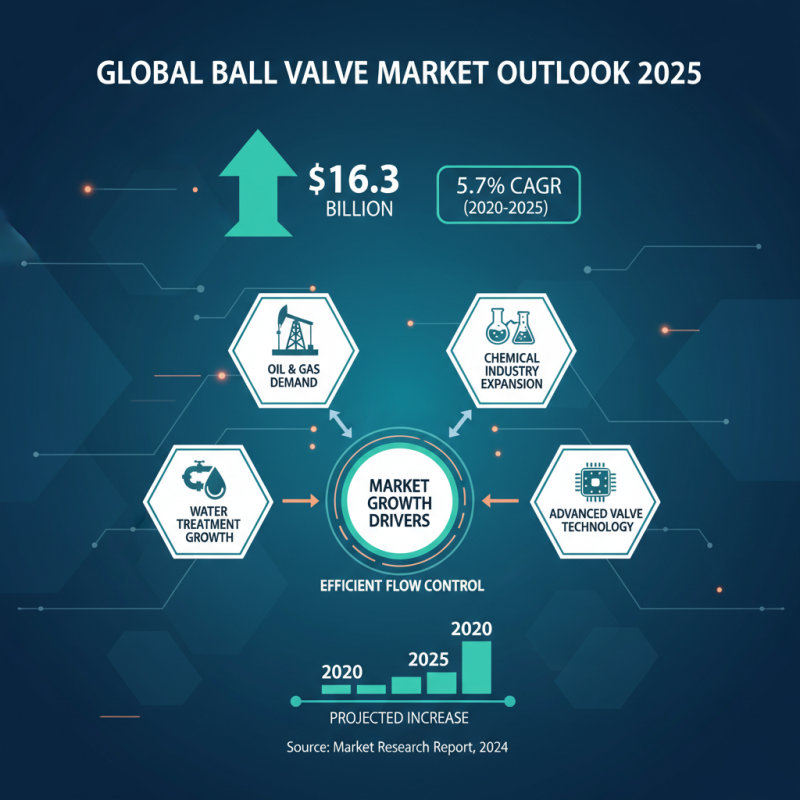

The ball valve market is expected to witness significant growth in 2025, driven by various factors including increased demand in the oil and gas sectors, as well as expansion in the chemical and water treatment industries. According to a recent market research report, the global ball valve market is projected to reach $16.3 billion by 2025, growing at a CAGR of 5.7% from 2020. This surge is attributed to the rising need for efficient flow control systems, coupled with advancements in valve technology that enhance durability and reliability.

Opportunities for ball valve suppliers are particularly pronounced in emerging markets, where industrialization and infrastructure development are accelerating. The Asia-Pacific region, in particular, is forecasted to make up a substantial share of this growth, with a compound annual growth rate higher than the global average. This trend is bolstered by increasing foreign investments and the establishment of manufacturing plants aimed at catering to local demand. Additionally, the growing emphasis on sustainability and energy efficiency is pushing industries to adopt advanced ball valve systems, which are known for their low-pressure drops and compact design, making them an attractive choice for various applications.

Related Posts

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

Unlocking Efficiency: How Lever Valves Can Reduce Energy Consumption by Up to 30% in Industrial Applications

-

Top 10 Tips for Choosing the Best Valve Suppliers for Your Projects

-

Top 5 Home Valve Solutions to Improve Your Plumbing Efficiency

-

Top 10 Valve Home Innovations to Watch in 2025

-

How to Choose the Right Saunders Valves for Your Applications