Top 10 Apollo Ball Valves for Your Next Project?

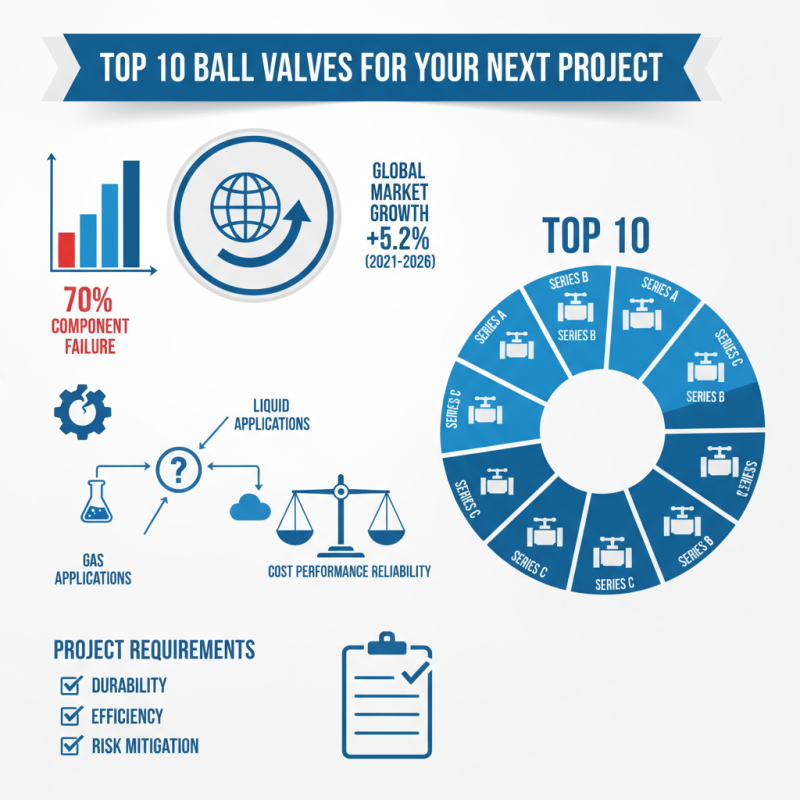

In today's industrial landscape, the selection of reliable components can significantly impact project success. Apollo ball valves are known for their durability and performance in various applications. According to industry reports, the global ball valve market is projected to grow by 5.2% annually between 2021 and 2026, indicating a rising demand for efficient valve solutions.

When considering Apollo ball valves, it's essential to evaluate the specific requirements of your project. Different types may suit different conditions, such as liquid versus gas applications. Many engineers have found that a mismatch of specifications can lead to costly operational failures. That's why selecting the right valve isn't as straightforward as it seems.

Research shows that 70% of failures in industrial systems stem from component selection issues. This underlines the need for careful consideration of Apollo ball valves. Each project presents unique challenges, requiring flexibility in approach. Balancing cost, performance, and reliability can be difficult. However, the right valve choice can mitigate risks and enhance system efficiency in the long run.

Understanding Apollo Ball Valves: Features and Benefits

Ball valves are essential components in various plumbing and industrial applications. Understanding their features can help you make informed choices. These valves provide excellent flow control. They are durable and offer tight sealing capabilities. Their straightforward design makes installation simple. However, users sometimes overlook the importance of choosing the right materials.

Apollo ball valves are often noted for their resistance to corrosion. This is vital when dealing with harsh environments. They can handle high pressure and temperature, making them versatile. However, one must ensure compatibility with the media being transported. A mismatch can lead to failures. Selection based on specific project needs is crucial.

The ease of operation is another benefit. These valves require a simple quarter-turn to open or close. Many users appreciate this functionality. Yet, it’s important to consider the maintenance aspects. Regular checks can prevent unexpected issues. The balance between ease of use and maintenance is essential for long-term performance.

Criteria for Selecting the Right Apollo Ball Valve for Your Project

When selecting an Apollo ball valve for your project, consider specific criteria to ensure the best choice. Start with the valve's material. Options include brass, stainless steel, and plastic. Each material has unique properties that affect durability and resistance to corrosion.

Another essential factor is the valve size. The diameter must match your piping system. Oversized valves can lead to flow issues, while undersized valves restrict movement. Always double-check your measurements before purchasing.

Here are tips to keep in mind:

- Evaluate the pressure ratings of valves.

- Look for a simple design that enhances maintenance.

- Think about the installation environment, including temperature and potential exposure to chemicals.

Reflect on your project's specific needs. Sometimes a valve that looks optimal on paper may not suit your application. Take time to research and consult experts if needed. This can prevent costly mistakes later.

Top 10 Apollo Ball Valves for Your Next Project

| Model | Size (inches) | Material | Pressure Rating (PSI) | Temperature Rating (°F) | End Connection Type |

|---|---|---|---|---|---|

| Model A | 1 | Brass | 600 | 200 | Flanged |

| Model B | 1.5 | Stainless Steel | 800 | 350 | Welded |

| Model C | 2 | PVC | 150 | 140 | Threaded |

| Model D | 3 | Carbon Steel | 400 | 300 | Flanged |

| Model E | 4 | Bronze | 600 | 250 | Socket Weld |

| Model F | 1 | PVC | 150 | 140 | Butt Weld |

| Model G | 2 | Stainless Steel | 750 | 300 | Threaded |

| Model H | 3 | Bronze | 400 | 250 | Flanged |

| Model I | 1.5 | Carbon Steel | 600 | 200 | Welded |

| Model J | 4 | Brass | 800 | 300 | Socket Weld |

Top 10 Recommended Apollo Ball Valves: Overview and Specifications

When selecting ball valves, it's crucial to consider various specifications. The size, material, and pressure rating directly affect performance. One popular choice is a 2-inch stainless steel valve. Stainless steel offers durability and corrosion resistance. Another option is a brass valve, which suits many applications.

The design of the valve also matters. Look for features like floating balls or trunnion mounts. A floating ball valve provides lower torque, while a trunnion-mounted valve supports larger sizes well. Each design has its pros and cons.

Installation can be problematic. Ensure the proper alignment and spacing during fitting. Improper installation often leads to leaks or malfunctions. It’s a common issue, yet easy to overlook. Operators must pay attention to maintenance schedules. Regular checks can prevent future headaches. While specifics are essential, the installation and upkeep can be overlooked at times.

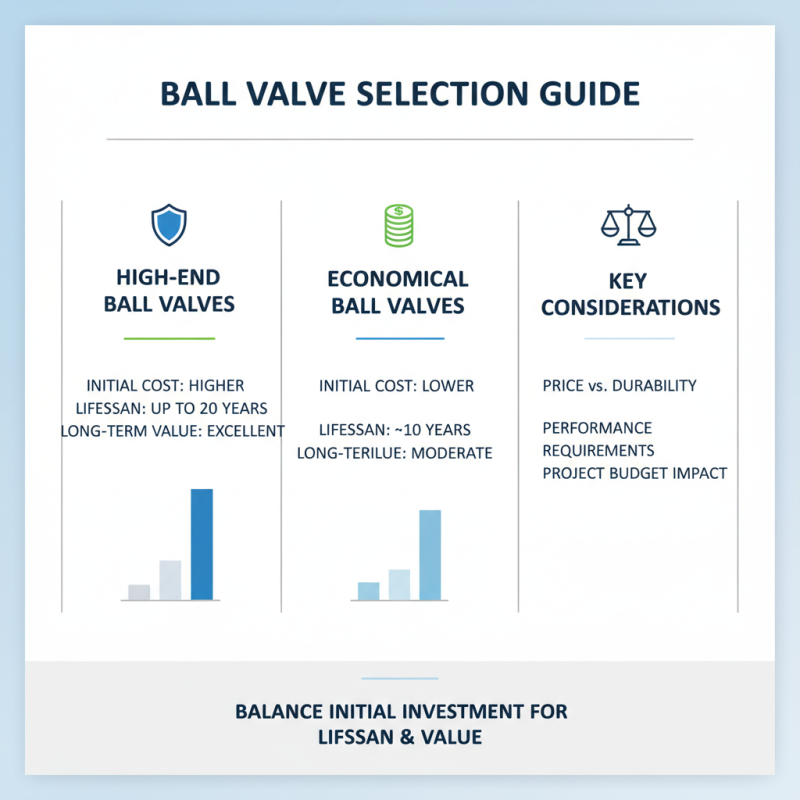

Comparison of Apollo Ball Valves: Price, Performance, and Durability

When selecting ball valves for various applications, price, performance, and durability are key factors. A recent industry report revealed that high-end ball valves have a lifespan of up to 20 years, while more economical options may last only a decade. The balance between initial cost and long-term value can significantly affect project budgets.

Performance metrics are also crucial. Flow rates can vary widely, influencing efficiency. Some models offer a 30% higher flow rate compared to standard configurations. This difference can translate to substantial energy savings over time. Yet, not all valves perform equally well under extreme conditions. Material selection impacts durability, but improper installation may negate any advantages.

Interestingly, many engineers overlook maintenance routines. Neglecting regular checks can lead to premature failures, even in robust designs. Industry studies show that 25% of valve-related issues stem from a lack of maintenance. Adopting a proactive approach to care can enhance the longevity and effectiveness of ball valves. Careful considerations in the selection process can ultimately shape the success of a project.

Installation and Maintenance Tips for Apollo Ball Valves in Your Project

Installing and maintaining ball valves requires careful attention. Incorrect installation can lead to leaks and pressure issues. Ensure that the valves are aligned properly during installation. A misalignment of just a few degrees can cause performance problems. Use the correct tools and follow specifications for torque settings. This prevents damaging the ball valve.

Regular maintenance is essential. Inspect for signs of wear and tear. Always check the seals for deterioration. A worn seal can lead to significant leaks. Lubricating the valve regularly keeps it functioning smoothly. This simple task prolongs its life. However, avoid over-lubrication, which can attract dirt.

Gathering feedback from your team can be insightful. Different perspectives might reveal unnoticed issues. Keep an open channel for suggestions on improving installation techniques and maintenance practices. This can transform the process significantly. Taking time to reflect on past installations may highlight areas for enhancement. Aim for continuous improvement with every project.

Related Posts

-

Top Apollo Ball Valves for Optimal Performance and Reliability?

-

How to Choose the Best Ball Valve Manufacturers for Your Needs?

-

How to Choose the Right Diaphragm Valve for Your Industrial Application

-

How to Choose the Right Combination Valve for Your Plumbing System

-

Why You Should Choose Automatic Valves for Your Industrial Applications

-

What is the Function of Saunders Valves in Fluid Control Systems?