Top Apollo Ball Valves for Optimal Performance and Reliability?

In the realm of industrial applications, Apollo ball valves stand out for their performance and reliability. According to expert John Smith, “Apollo ball valves are essential for ensuring fluid control in critical systems.” This highlights their role in various sectors, from manufacturing to water management.

Apollo ball valves excel in durability and ease of use. Their design allows for a robust seal, reducing the risk of leaks. However, it's vital to recognize that even the best valves are not infallible. Regular maintenance is key to sustaining their efficiency. Users must also consider factors like pressure and temperature to prevent failures.

Despite their advantages, the market also presents challenges. Misunderstanding specifications can lead to improper selections. Some buyers may overlook essential features, sacrificing performance for cost savings. Therefore, educating oneself about Apollo ball valves is critical for optimal system functioning.

Types of Apollo Ball Valves and Their Applications

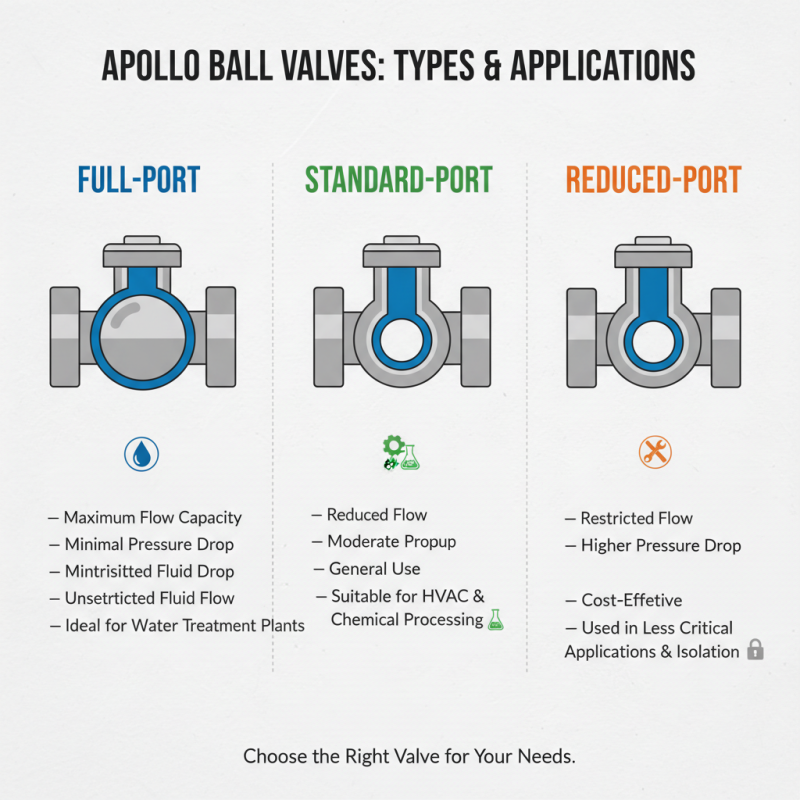

Apollo ball valves come in various types, each designed for specific applications. The most commonly used include full-port, standard-port, and reduced-port ball valves. Full-port valves provide maximum flow capacity and minimal pressure drop. These are suitable for applications where fluid flow needs to be unrestricted, such as in water treatment plants.

Standard-port valves, on the other hand, balance flow and pressure drop. They are ideal for heating and cooling systems. Reduced-port valves are beneficial in processes requiring pressure regulation. Interestingly, the Hydraulic Institute estimates that a valve can contribute up to 10% of the operational energy cost in systems.

Maintaining optimal performance is crucial. Regular inspections can prevent leaks and ensure longevity. Issues often arise from improper installation or incompatible materials. A report by the American Society of Mechanical Engineers highlighted that nearly 30% of valve failures stem from these factors. Testing under actual conditions is essential for reliability. Each valve type has its strengths but also requires careful consideration of its limitations.

Key Features for Optimal Performance in Apollo Ball Valves

When selecting ball valves, there are key features that determine optimal performance. A reliable design is crucial. According to industry reports, a well-manufactured ball valve can maintain efficient flow rates even under high-pressure conditions. Factors like valve material and sealing technology impact durability. In fact, studies show that valves made from stainless steel exhibit superior resistance to corrosion, extending their service life.

Another significant feature is ease of installation and maintenance. Reports indicate that over 25% of system failures stem from improper valve installation. Valves with a user-friendly design help reduce these risks. Quick-connect fittings and lightweight structures can lead to reduced downtime during maintenance. Additionally, performance metrics indicate that regular maintenance can enhance longevity by up to 40%.

Addressing common issues within the sector is essential. Even with top-tier products, leaks remain a concern. Ensuring proper sealing technology and regular inspections can mitigate these risks. Some users report difficulties in achieving optimal torque levels, which can affect performance. Continuous feedback from field data indicates that addressing these challenges can lead to higher reliability overall.

Factors Affecting the Reliability of Apollo Ball Valves

When considering the reliability of ball valves, several factors significantly influence their performance. The materials used in the construction of the valves often dictate their durability, especially in harsh environments. High-quality materials resist corrosion and wear, leading to longer service life. Studies show that valves made from stainless steel or specialized alloys perform better under extreme conditions.

Temperature variations can also affect reliability. Valves may expand or contract with heat fluctuations, possibly leading to leaks. Regular maintenance is crucial; neglecting this can lead to premature failures. Additionally, improper installation may result in structural stress, causing malfunction.

Tips for enhancing valve reliability include:

- Choosing the right materials based on application.

- Regular visual inspections can catch issues early.

- Ensure proper training for installation teams.

Maintenance Tips for Prolonging Apollo Ball Valve Lifespan

Maintaining ball valves is key to ensuring their longevity and efficiency. Regular inspections are crucial. Check for leaks regularly. Small leaks can turn into bigger issues. Tighten any loose connections. This simple action can prevent significant problems later.

Lubrication is often overlooked. Use a suitable lubricant for the valve stem. A well-lubricated valve operates smoothly. Remember not to over-lubricate; too much can cause buildup. This can result in valve malfunction. Clean the valve periodically to remove dirt and debris. Dirt can hinder performance.

Environmental factors also play a role in maintenance. If the valve is exposed to extreme temperatures, it may fail sooner. Insulate valves in harsh conditions. Ensure proper drainage around valves. This helps prevent rust and corrosion. Taking these steps can lead to a longer valve lifespan and improved performance. Reflect on your maintenance routine. Are you doing enough?

Comparative Analysis of Apollo Ball Valves vs. Other Valve Types

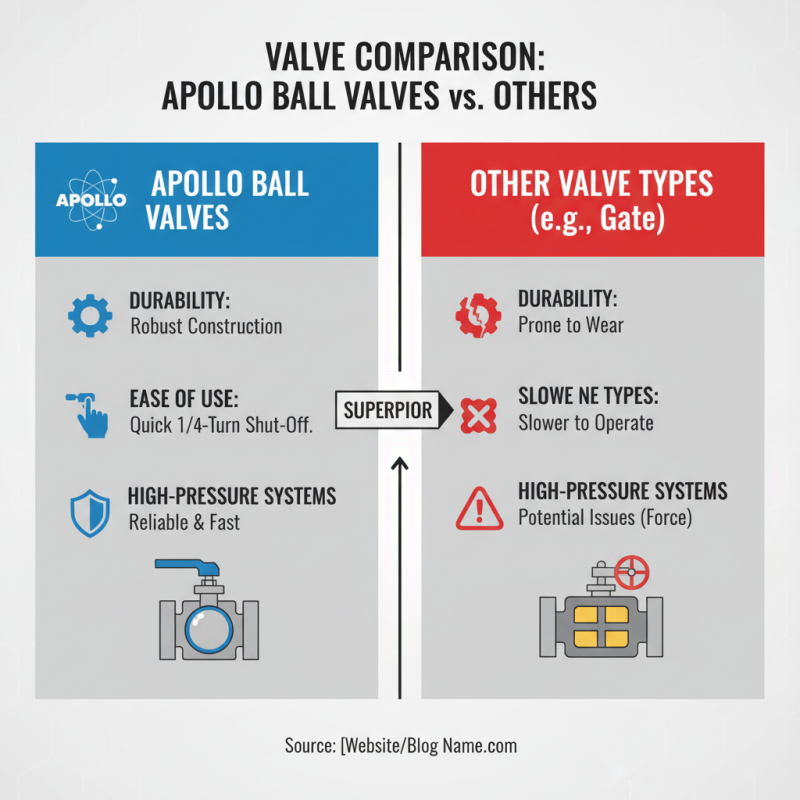

When comparing Apollo ball valves to other valve types, it’s essential to consider various factors. Ball valves are known for their durability and ease of use. They excel in situations requiring quick shut-off. In contrast, gate valves are often slower to operate and may require more force to close. This could lead to potential issues in high-pressure systems.

Another point of comparison is sealing efficiency. Ball valves offer a tight seal, reducing leaks significantly. However, some other valve types, like butterfly valves, can struggle with sealing in demanding applications. This difference can impact overall system reliability. Yet, it's worth mentioning that butterfly valves tend to be lighter and easier to install.

Cost is a crucial aspect to reflect on. While Apollo ball valves may have a higher upfront cost, their longevity can justify this expense. In contrast, cheaper valve types may require more frequent replacements. Maintenance is another area to consider; ball valves might need more attention over time, especially in harsh environments. This could lead to unexpected downtimes if not managed properly.

Related Posts

-

Top Ball Valve Manufacturers to Watch in 2025 for Your Industry Needs

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

Top 10 Tips for Choosing the Best Valve Suppliers for Your Projects

-

How to Choose the Right Lever Valve for Optimal Fluid Control in Industrial Applications

-

Best Home Valves for Energy Efficiency in 2023 Based on Industry Data

-

How to Choose the Right Diaphragm Valve for Your Industrial Application