2025 Top 4 Way Valve Innovations and Market Trends Driving Efficiency

As industries strive for greater efficiency in fluid control systems, innovations in valve technology are paramount. The 4 way valve, a crucial component in applications ranging from hydraulics to pneumatic systems, has seen remarkable advancements in design and functionality. Industry expert Dr. Emily Roberts, a leading authority on valve engineering, emphasizes the importance of these innovations by stating, "The evolution of the 4 way valve is set to redefine operational efficiency and adaptability across various sectors."

With the demand for streamlined processes and reduced energy consumption growing, the 4 way valve is at the forefront of this transformation. New developments are focusing on improved materials and smart technology integration, ensuring that these valves not only perform better but also adapt to the changing needs of modern applications. Understanding the latest trends in 4 way valve technology is essential for engineers and managers seeking to enhance system performance while minimizing downtime.

As we delve deeper into the innovations and market trends of 2025, it becomes clear that the advancements in the 4 way valve sector are not merely incremental; they hold the potential to fundamentally shift how industries approach fluid management, paving the way for a more efficient future.

Revolutionary Materials Enhancing Valve Durability and Performance

The evolution of valve technology is witnessing remarkable advancements, particularly with the introduction of revolutionary materials that significantly enhance durability and performance. In today's industrial landscape, the demand for valves that can withstand extreme conditions while maintaining efficiency is at an all-time high. New materials such as ceramic composites and advanced polymers are being utilized to create valves that are not only lightweight but also resistant to corrosion and wear. These innovations help to extend the lifespan of valves, reduce maintenance costs, and improve overall system reliability.

Furthermore, the integration of smart materials in valve manufacturing is transforming operational capabilities. Smart materials respond dynamically to changes in temperature, pressure, and flow, allowing for better adaptability in diverse environments. This capability not only increases the efficiency of control systems but also provides real-time data analytics for predictive maintenance. As industries continue to prioritize sustainability and operational efficiency, the adoption of these advanced materials will be pivotal in driving innovation within the valve market, ultimately leading to enhanced performance and reduced environmental impact.

Smart Technologies Transforming Valve Control and Operations

The evolution of smart technologies is fundamentally transforming valve control and operations, enhancing both efficiency and reliability in various industries. Innovations such as IoT-enabled sensors and predictive analytics are at the forefront, allowing for real-time monitoring and data collection. These advancements enable operators to anticipate maintenance needs, reducing downtime and extending the lifecycle of valve systems.

Moreover, the integration of artificial intelligence and machine learning into valve operations is driving significant improvements in automation and decision-making. Smart valves can adapt to changing conditions without human intervention, optimizing flow control and energy consumption. As industries increasingly prioritize sustainability and operational efficiency, these smart technologies will play a crucial role in meeting regulatory requirements and minimizing environmental impact.

The push towards digital transformation in valve management not only streamlines operations but also fosters a proactive approach to maintenance and performance optimization.

Energy Efficiency Improvements in Valve Design and Functionality

In recent years, the valve industry has seen significant advancements aimed at enhancing energy efficiency through innovative design and functionality. Engineers are focusing on developing smart valves equipped with sensors and IoT technology, allowing for real-time monitoring and adjustment of flow rates. This integration not only reduces energy consumption but also minimizes wear and tear on the components, leading to longer service life and lower maintenance costs. Such innovations are particularly crucial in sectors like water treatment and oil and gas, where efficiency directly impacts operational costs and environmental sustainability.

Moreover, manufacturers are increasingly exploring advanced materials and manufacturing techniques that contribute to lighter, more efficient valve designs. For instance, the use of composite materials can reduce friction losses, resulting in lower energy requirements during operation. Additionally, the shift towards modular valve systems allows for easier customization and scalability, further enhancing operational efficiency. As these trends continue to evolve, companies are not only achieving better performance but are also aligning with global sustainability goals, making energy-efficient valve designs a vital component of modern industrial practices.

Integration of IoT in Valve Systems for Real-Time Monitoring

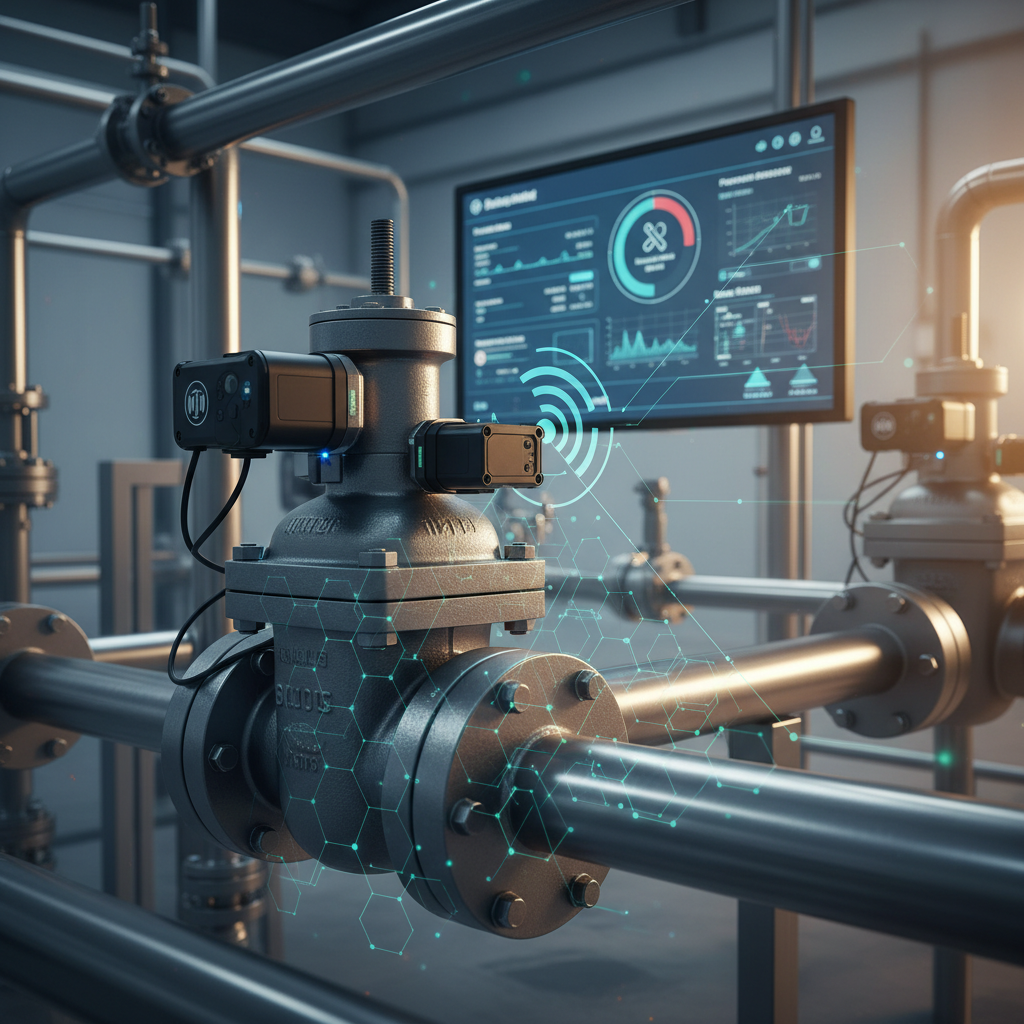

The integration of the Internet of Things (IoT) in valve systems marks a significant advancement in industrial automation and efficiency. By embedding sensors and connectivity features into valve systems, operators can monitor real-time performance metrics, providing immediate insights into the operational status of various processes. This technology facilitates predictive maintenance, allowing users to anticipate failures before they occur, thus minimizing downtime and optimizing maintenance schedules.

Furthermore, IoT-enabled valves support more efficient resource utilization by enabling smarter control of fluid dynamics. With real-time data, operators can adjust valve settings dynamically, tailoring operations to meet fluctuating demand without manual intervention. This not only enhances operational efficiency but also contributes to energy savings and reduced waste. The synergy between IoT and valve technology is driving a transformative shift in how industries approach system management, paving the way for greater automation and improved operational resilience.

Emerging Market Trends Shaping the Future of Valve Innovations

Emerging market trends are pivotal in shaping the future of valve innovations, particularly in the water management and automotive sectors. As industries transition towards sustainability, the demand for more efficient and versatile valves has surged. Recent reports indicate that the automotive valves market is expected to witness substantial growth, with strategic analyses revealing a forecast extending to 2034. This indicates a steady evolution driven by technological advancements and increasing regulations surrounding emissions and energy efficiency.

In the water management industry, a detailed exploration of recent trends highlights the significance of smart water technologies. This shift is reflected in the rise of startups focused on innovative solutions, with over 2400 companies actively contributing to this dynamic field. Furthermore, the PTFE and PFA lined diaphragm valves market is projected to reach USD 498 million by 2035, with an anticipated CAGR of 5.7%. These figures underscore the growing necessity for reliable valve systems that enhance operational efficiency and sustainability in various sectors. As these trends continue to unfold, industry stakeholders must adapt to maintain their competitive edge.

2025 Top 4 Way Valve Innovations and Market Trends Driving Efficiency

This bar chart illustrates the projected efficiency improvements associated with four key valve innovations for the year 2025. The data highlights the expected percentage increase in operational efficiency driven by each innovation.

Related Posts

-

Unlocking Efficiency: How Lever Valves Can Reduce Energy Consumption by Up to 30% in Industrial Applications

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

Understanding the Importance of Shut Off Valves in Home Plumbing Systems: A Comprehensive Guide

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering