Top 10 Saunders Valves Benefits You Should Know

In the world of industrial fluid control, Saunders valves have gained a reputation for their reliability and efficiency. As noted by industry expert Dr. Emily Harrington, "The innovations in Saunders valves design have transformed the way industries manage fluid flow, providing unparalleled performance and safety." This statement encapsulates the essence of what makes Saunders valves a preferred choice among professionals in various sectors.

Understanding the benefits of Saunders valves is crucial for engineers and facility managers alike. These valves not only offer exceptional durability and precision but also come with features that enhance operational efficiency and reduce maintenance costs. In this article, we will explore the top ten benefits of Saunders valves, shedding light on how they contribute to optimizing processes across numerous applications. Whether you are involved in pharmaceutical manufacturing or water treatment, the strategic implementation of Saunders valves can lead to significant improvements in productivity and reliability.

Understanding the Engineering Excellence of Saunders Valves

Saunders valves are renowned for their engineering excellence, making them a preferred choice in various industrial applications. Their design focuses on durability and efficiency, ensuring optimal performance even in challenging environments. With cutting-edge materials and innovative manufacturing techniques, Saunders valves stand out for their reliability, providing long-lasting solutions that reduce downtime and maintenance costs. These valves are engineered to handle different media types, making them versatile for use in sectors such as pharmaceuticals, food and beverage, and chemical processing.

Tip: When selecting valves for specific applications, consider the material compatibility with the media to ensure longevity and prevent leaks.

The precision in the engineering of Saunders valves allows for easy operation, whether manual or automated. Their compact design often facilitates space-saving installations while maintaining high flow rates. Moreover, these valves are designed with user-centered ergonomics, simplifying the installation and maintenance processes.

Tip: Always check for quality certifications when choosing valves for critical applications to ensure compliance with industry standards.

By prioritizing engineering excellence, Saunders valves not only enhance system performance but also contribute to overall operational safety and efficiency in industrial settings. The thoughtful integration of technology in their design ensures that they meet the varying demands of modern industries effectively.

Durability and Reliability: Key Features of Saunders Valves

When selecting industrial valves, durability and reliability are paramount. Saunders valves are engineered to meet the rigorous demands of various applications, showcasing exceptional longevity and performance under challenging conditions. According to a study by the Industrial Valve Market Analysis Report, the global valve industry is projected to reach USD 100 billion by 2025, driven largely by the increasing need for durable solutions that can withstand corrosive environments and high pressures. Saunders valves, with their robust construction, demonstrate resistance to wear and tear, translating to reduced maintenance costs and downtime for businesses.

In addition to their inherent durability, the reliability of Saunders valves is supported by advanced design features that cater to a variety of operational requirements. A report from the American Society of Mechanical Engineers highlights that valve failure can lead to significant operational disruptions, emphasizing the need for equipment that can consistently perform without unexpected failures. The exceptional sealing capabilities and operational efficiency of Saunders valves help mitigate these risks, ensuring that critical processes run smoothly, making them a staple in industries such as pharmaceuticals and chemicals where precision and safety are non-negotiable.

Top 10 Saunders Valves Benefits You Should Know

| Benefit | Description | Key Feature |

|---|---|---|

| Durability | Designed to withstand harsh operating environments | Robust Materials |

| Reliability | Consistent performance over time | Quality Assurance |

| Corrosion Resistance | Effective in preventing rust and degradation | Special Coatings |

| Ease of Maintenance | Simple design allows for quick servicing | Accessible Components |

| Versatility | Suitable for various applications and mediums | Wide Range of Options |

| Pressure Resistance | Can handle high-pressure situations | Engineered for Strength |

| Leak-Free Operation | Designed to prevent fluid leaks | Sealing Technology |

| Customization | Can be tailored to specific operational needs | User-Specific Configurations |

| Safety Features | Incorporates features to enhance operational safety | Integrated Safety Solutions |

| Cost Efficiency | Long lifespan reduces overall costs | Economical Choice |

Versatility of Applications: How Saunders Valves Are Used in Industries

Saunders valves are renowned for their versatility across a multitude of industries, primarily due to their robust design and reliable performance in various applications. From pharmaceutical manufacturing to food processing and water treatment, these valves provide a reliable solution for controlling the flow of fluids. According to the Global Valve Market report, the demand for versatile valve designs is projected to grow at a CAGR of 4.2% from 2021 to 2026, highlighting the increasing reliance on such components in critical industries. The adaptability of Saunders valves to operate under extreme temperatures and pressures makes them suitable for environments where traditional valves may fail.

In the pharmaceutical industry, for example, the strict compliance with sanitary standards necessitates the use of reliable valve systems. Saunders valves, designed to minimize dead legs and facilitate easy cleaning, ensure that production processes remain sterile, thereby adhering to FDA regulations. Additionally, their use in water treatment systems contributes to the effective management of waste and safe distribution of potable water. A recent industry study indicated that using high-quality valves can reduce maintenance costs by up to 20%, underscoring the financial benefits of investing in durable and efficient valve systems.

**Tip:** When selecting valves for specific applications, it's crucial to consider not only the operational requirements but also the long-term maintenance implications. Regular audits and utilizing predictive maintenance tools can enhance the lifespan of valves and ensure optimal performance.

Moreover, the application of Saunders valves is not limited to traditional sectors. Their integration in emerging fields like renewable energy, particularly in biogas production, showcases their flexibility. With the renewable energy sector projected to grow significantly, the demand for specialized fluid control systems is expected to rise, further cementing the role of such valves in innovative applications.

**Tip:** Implementing a comprehensive training program for staff on valve maintenance can greatly improve safety and operational efficiency while extending the service life of the equipment.

Top 10 Benefits of Saunders Valves in Various Industries

This chart illustrates the versatility of Saunders Valves across different industries, showcasing their top applications and the corresponding percentage of usage.

Energy Efficiency: The Cost-Effectiveness of Saunders Valves

Energy efficiency is a crucial factor in the operational costs of industrial facilities, and the utilization of high-performance valves can significantly impact overall energy expenditure. The implementation of advanced valve technology, such as those designed with precision engineering, can reduce energy loss and enhance system reliability. According to a report from the International Energy Agency (IEA), optimized valve mechanisms can improve energy efficiency in fluid systems by up to 20%, contributing to substantial cost savings over time.

In addition to direct energy savings, efficient valve solutions can lead to a decrease in maintenance costs. A study by the American Society of Mechanical Engineers (ASME) indicated that maintenance-related expenses account for approximately 10-30% of the total operating budget in industrial applications. By investing in energy-efficient valve systems, businesses can minimize wear and tear, leading to longer intervals between necessary repairs and replacements, thus further enhancing the cost-effectiveness of their operations. The choice of valves that promote energy efficiency not only supports sustainability efforts but also aligns with the industry's broader goals of reducing operational costs while optimizing performance.

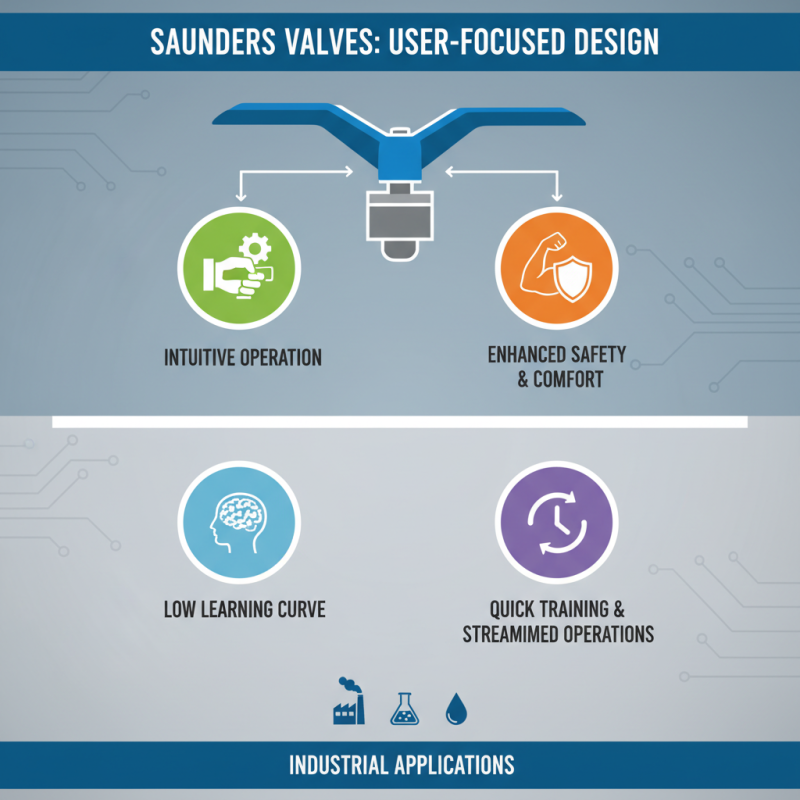

User-Friendly Design: Benefits of Operating Saunders Valves

Saunders valves are designed with user-friendliness at their core, making them an ideal choice for various industrial applications. One of the standout features of these valves is their intuitive operating mechanism, which allows for easy manipulation even in demanding environments. The ergonomic handle design ensures that operators can make adjustments comfortably and efficiently, reducing the risk of operator fatigue and enhancing safety in the workplace. This thoughtful design consideration significantly lowers the learning curve for new users, allowing for quick training and streamlined operations.

Additionally, the versatility of Saunders valves contributes to their user-friendly nature. They can be easily integrated into existing systems, providing flexibility across different applications without necessitating extensive modifications. The straightforward assembly and maintenance processes further enhance their accessibility, allowing operators to perform routine checks and repairs with minimal downtime. This reliability and ease of use help users maintain consistent operational efficiency, making Saunders valves a preferred choice for those seeking practical solutions that prioritize ease of use and performance.

Related Posts

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Understanding the Importance of Shut Off Valves in Home Plumbing Systems: A Comprehensive Guide

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

2025's Top 5 Flow Valve Innovations You Need to Know About