Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

In contemporary plumbing systems, the combination valve plays a pivotal role in ensuring both efficiency and safety. According to a report from the International Association of Plumbing and Mechanical Officials (IAPMO), approximately 30% of plumbing-related failures can be attributed to outdated or improperly functioning valves. Combination valves, which integrate multiple functions such as pressure regulation, backflow prevention, and temperature control, have emerged as essential components that enhance system performance and reliability.

By addressing critical issues such as water hammer and thermal expansion, these valves not only optimize water usage but also contribute to energy savings, making them a smart investment for modern households. Understanding the intricacies of combination valves is thus vital for plumbing professionals and homeowners alike, as it can lead to improved system longevity and user satisfaction.

By addressing critical issues such as water hammer and thermal expansion, these valves not only optimize water usage but also contribute to energy savings, making them a smart investment for modern households. Understanding the intricacies of combination valves is thus vital for plumbing professionals and homeowners alike, as it can lead to improved system longevity and user satisfaction.

The Essential Functions of Combination Valves in Plumbing Systems

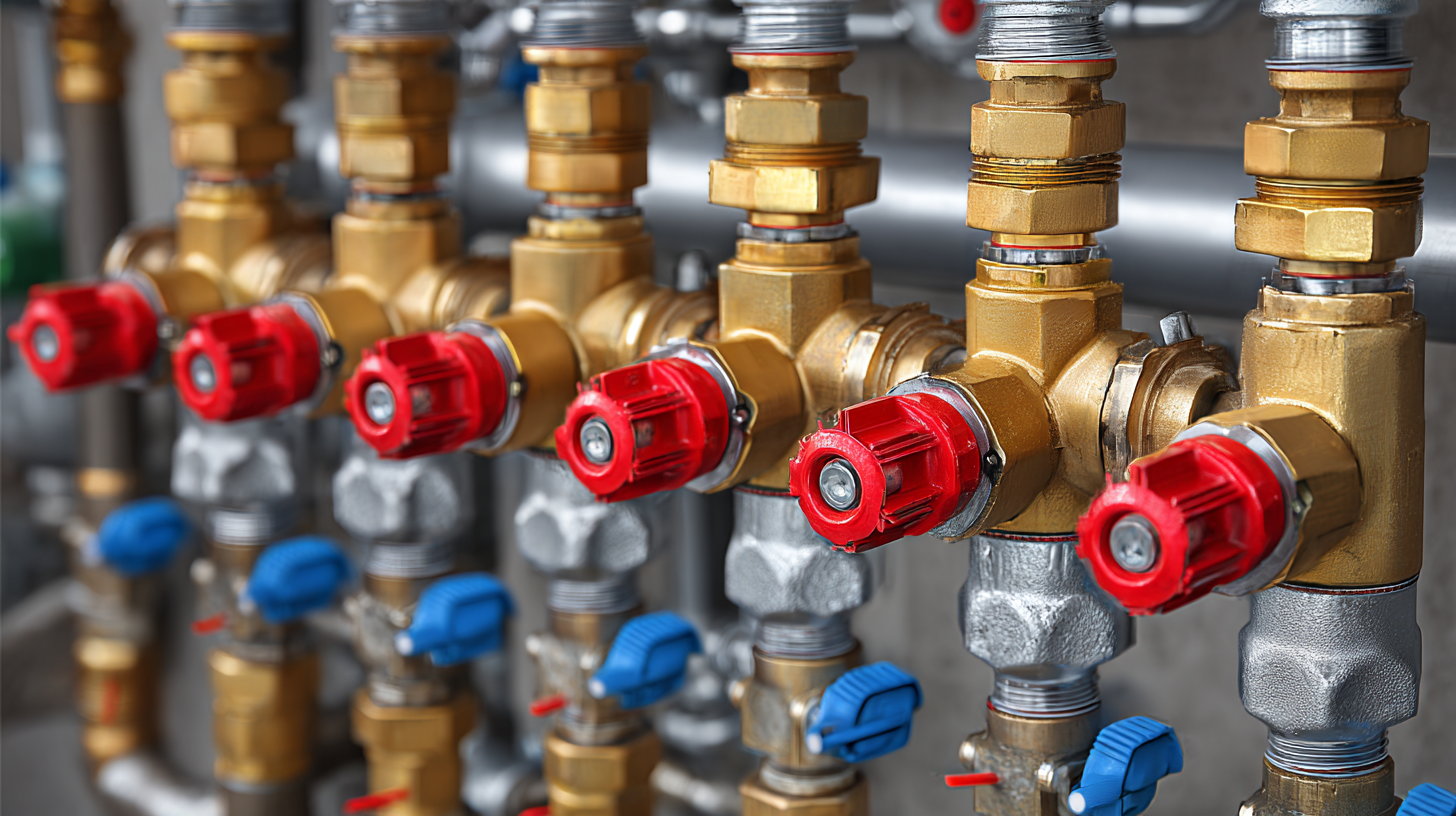

Combination valves play a crucial role in modern plumbing systems by integrating multiple functions into a single device. These valves are essential for regulating water flow, maintaining the desired temperature, and providing safety features to protect against potential hazards such as backflow and flooding. According to recent trends in the plumbing component market, the demand for efficient and multifunctional valves is rising, particularly in multi-occupancy buildings where effective management of water resources is critical.

Tips: When selecting a combination valve, consider systems that offer easy temperature control and improved flow regulation, which can enhance the comfort and efficiency of shower experiences. Additionally, ensure that the selected valve is compliant with current plumbing codes to avoid costly adjustments later. Regular maintenance of these valves is also vital; check for any signs of wear or malfunction to prevent disruptions in your plumbing system.

Furthermore, with the growing emphasis on safeguarding buildings against environmental risks, combination valves equipped with backwater prevention features are becoming increasingly important. These valves help mitigate the risks associated with sewer backups and stormwater flooding, enhancing the safety of residential and commercial properties alike.

Key Types of Combination Valves and Their Applications in Modern Plumbing

Combination valves are integral components in modern plumbing systems, particularly in multi-occupancy buildings where diverse needs must be met effectively. Among the key types of combination valves are thermostatic mixing valves (TMVs), which are designed to blend hot and cold water, delivering water at a consistent, safe temperature. This functionality is crucial not only for user comfort but also for safety, as TMVs can prevent scalding incidents, reducing the risk of injuries in households and public facilities. According to industry reports, the implementation of TMVs has been shown to significantly improve safety standards, with a notable reduction in hot water-related accidents.

The relevance of combination valves extends beyond basic safety; they also play a vital role in enhancing energy efficiency in plumbing systems. Effective use of these valves can lead to reduced energy consumption by ensuring that water is heated to the optimal temperature for use. Reports indicate that buildings equipped with modern plumbing solutions that include TMVs can achieve energy savings of up to 20%. This not only contributes to lower utility bills for residents but also aligns with sustainability efforts by decreasing overall energy demands. As plumbing systems evolve, the importance of combination valves in enhancing functionality, safety, and efficiency continues to grow, underscoring their critical role in the design of modern plumbing installations.

Performance Metrics: Evaluating the Efficiency of Combination Valves

Combination valves play a crucial role in modern plumbing systems by ensuring efficient water flow and maintaining pressure balance. Evaluating their performance is essential for understanding their efficiency in real-world applications. According to the American Society of Plumbing Engineers (ASPE), combination valves can reduce water waste by up to 30% when properly installed and maintained. This reduction is significant, especially as the plumbing industry faces increasing pressure to implement water conservation measures.

To quantify the efficiency of combination valves, it is vital to assess metrics such as flow rate, pressure drop, and response time. A recent report by the Plumbing Efficiency Research Coalition (PERC) indicated that high-efficiency combination valves exhibit a 15-20% lower pressure drop compared to standard models, enhancing overall system performance. Furthermore, valves equipped with advanced technology, such as smart sensors, can provide real-time data on water usage and pressure levels, allowing for proactive maintenance and reducing downtime. By focusing on these performance metrics, plumbing professionals can ensure the optimal functionality of their systems, leading to long-term reliability and sustainability.

Installation Best Practices for Combination Valves in Residential and Commercial Settings

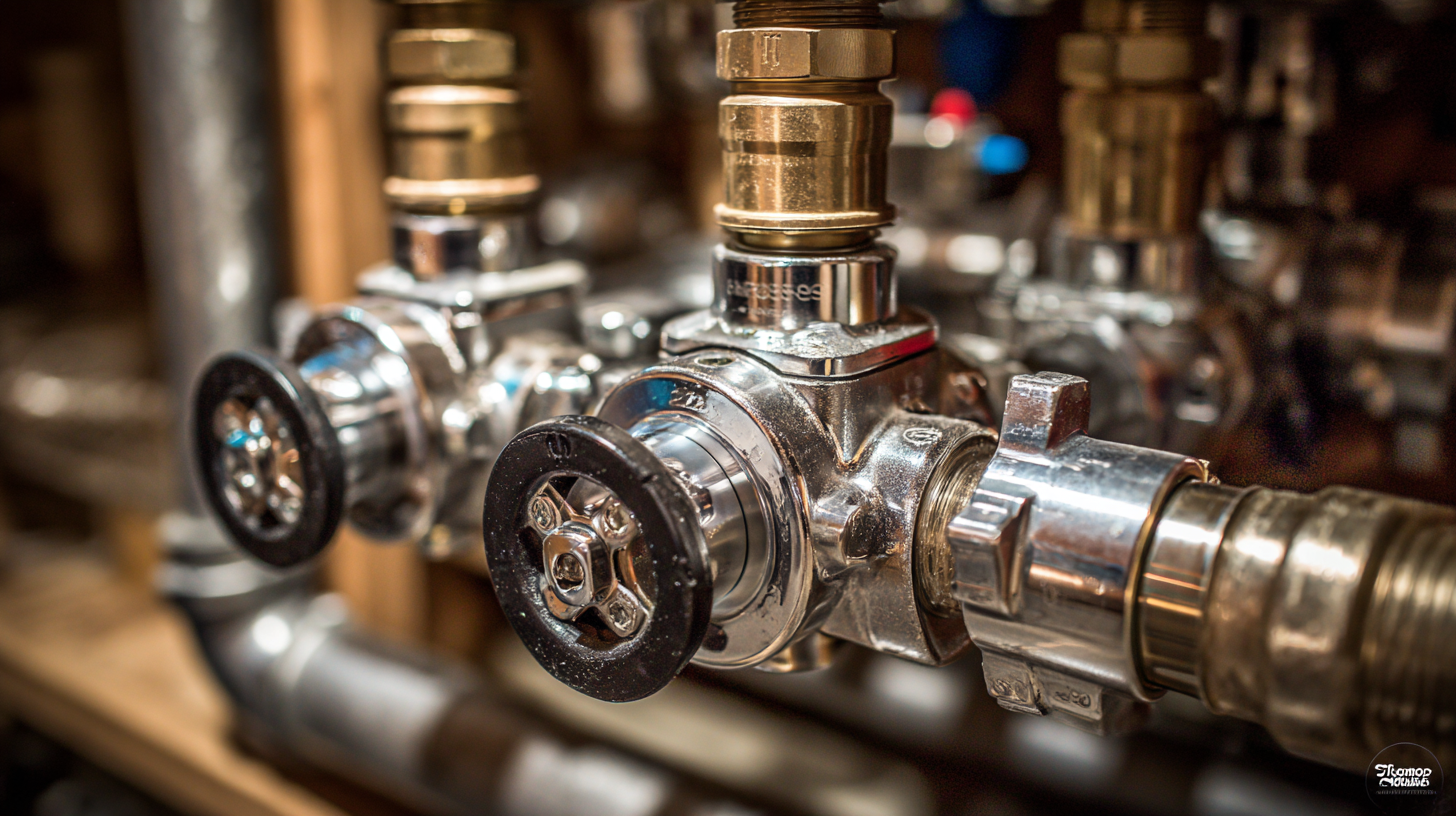

When installing combination valves in both residential and commercial settings, it is crucial to adhere to best practices to ensure optimal performance and safety. First, selecting the right valve type is essential, as combination valves serve multiple functions including pressure regulation, backflow prevention, and temperature control. Proper sizing according to the plumbing system's requirements prevents issues such as pressure drops or inefficiencies. Before installation, verify that all components, including fittings and pipes, are compatible with the valve specifications to avoid future complications.

Once the right combination valve is chosen, proper installation techniques must be followed. Begin by shutting off the water supply to the area, ensuring that no pressure remains in the pipes. Align the valve according to manufacturer instructions, ensuring that flow direction markers are respected. Tightening connections should be done carefully—over-tightening can lead to leaks or damage. After installation, conduct thorough testing by gradually restoring water flow to check for any signs of leakage or malfunctioning. Regular maintenance routines should also be established to monitor the valve’s effectiveness and to address any potential issues before they escalate.

Maintenance Guidelines to Enhance Longevity and Functionality of Combination Valves

Combination valves play a critical role in modern plumbing systems, facilitating efficient water flow and pressure control. However, to maximize their longevity and functionality, regular maintenance is essential. According to the Plumbing-Heating-Cooling Contractors Association (PHCC), approximately 30% of plumbing system issues arise from neglected valve maintenance. Regular inspections can help identify potential leaks or malfunctions before they escalate into costly repairs.

**Tip:** Schedule routine checks at least once a year, focusing on the seals and fittings of combination valves to ensure optimal performance. Keeping the valves clean and free of debris can also significantly reduce wear and tear.

Another key aspect of maintaining combination valves is ensuring proper water pressure. The American Society of Plumbing Engineers recommends keeping residential water pressure between 40 to 60 psi to not only enhance the efficiency of combination valves but also to prolong their lifespan. Over-pressurization can lead to premature valve failure and leaks, which can cause damage to your plumbing system.

**Tip:** Install a pressure gauge to monitor your water pressure regularly, making adjustments as necessary to stay within the recommended range. By adhering to these maintenance guidelines, homeowners can ensure their combination valves operate effectively and last longer.

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

| Valve Type | Operation Mechanism | Main Functions | Maintenance Frequency | Lifespan |

|---|---|---|---|---|

| Pressure Reducing Valve | Regulates upstream pressure | Maintains consistent pressure | Every 6 months | 10-15 years |

| Backflow Preventer | Prevents reverse water flow | Protects potable water supply | Annually | 5-10 years |

| Pressure Relief Valve | Relieves excess pressure | Protects against overpressure | Every 6 months | 10-12 years |

| Combining Valve | Combines several functions | Regulates and prevents backflow | Annual check-up | 15-20 years |