What is a Recirculation Valve and How Does It Work?

The recirculation valve plays a crucial role in optimizing system efficiency. Its primary function is to regulate fluid flow within various industries, particularly in heating and cooling systems. According to a report by the International Energy Agency (IEA), implementing efficient recirculation valves can lead to energy savings of up to 30%. This is significant as energy efficiency becomes increasingly important in today's climate-conscious world.

In terms of functionality, the recirculation valve ensures that fluids are redirected, reducing waste and maintaining the desired temperature. However, not all systems utilize these valves effectively. Many installations still operate with outdated technology, losing potential efficiency gains. Consequently, reflecting on previous analyses highlights a noticeable gap in performance.

Moreover, the lack of proper maintenance can hinder the performance of recirculation valves. This neglect often results in increased energy consumption. Regular checks and timely replacements are essential for maintaining optimal functionality. Addressing these areas can lead to improved operational efficiency and a reduction in environmental impact.

What is a Recirculation Valve?

A recirculation valve is an essential component in various systems. It allows the controlled flow of fluids. Typically, you find it in water heating systems or hydraulic machinery. When the system operates, this valve ensures that fluid circulates efficiently.

The primary function is to manage pressure. Without it, pressure could rise too high or drop too low, which can be inefficient. The valve opens and closes based on specific conditions. This regulation helps maintain the system's balance. However, some might overlook routine checks.

Neglecting valve maintenance can lead to failures. Understanding how a recirculation valve works is vital. It helps pinpoint issues in fluid dynamics. You might find it challenging at first, yet recognizing its role is the key to efficient operation.

The balance between flow and pressure is crucial. If the system isn’t performing well, it might be time to reflect on the valve's condition.

The Purpose of a Recirculation Valve in Engine Systems

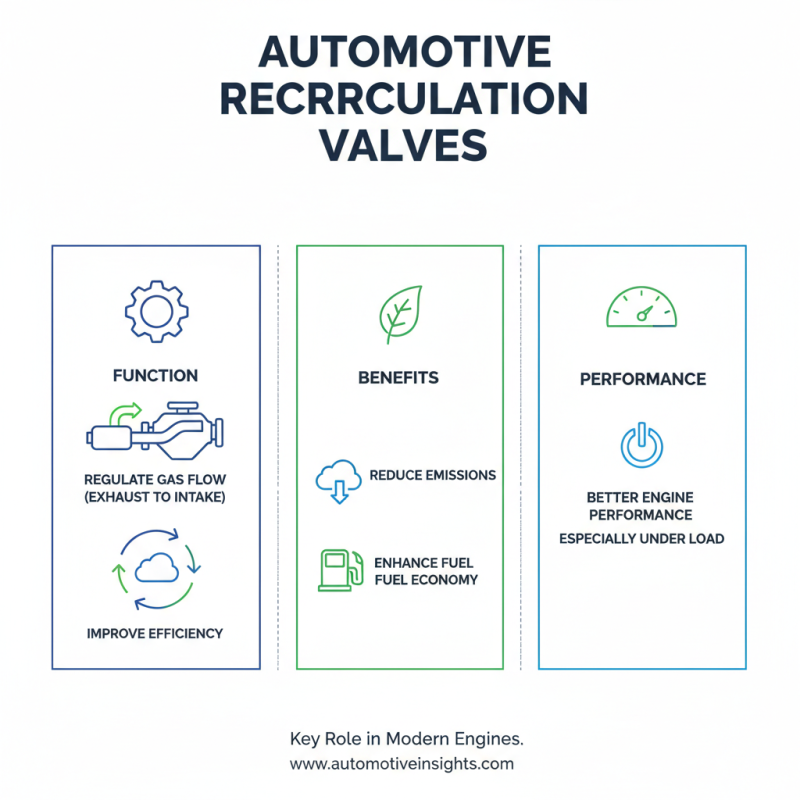

A recirculation valve plays a crucial role in engine systems. Its main purpose is to manage the flow of air and exhaust gases. By regulating these flows, the valve ensures that the engine runs efficiently. This efficiency can lead to better fuel economy and reduced emissions.

When the engine is under load, the recirculation valve opens. This allows a portion of exhaust gases to re-enter the intake system. The gases mix with fresh air, which helps in burning excess fuel. However, if the valve fails, it can lead to performance issues. The engine may stall or lose power. Regular checks can prevent these problems.

In some cases, drivers might notice strange sounds or flickering dashboard lights. These can signal an issue with the valve. Ignoring such signs can lead to costly repairs. Keeping an eye on engine performance is vital for maintaining a healthy system. Addressing small concerns can save time and money later.

What is a Recirculation Valve and How Does It Work?

| Dimension | Details |

|---|---|

| Function | Regulates air flow in engine systems |

| Location | Typically found in turbocharged engines |

| Operation Mechanism | Diverts excess air back to the intake |

| Advantages | Improves engine efficiency and performance |

| Potential Issues | Can cause turbo lag if malfunctioning |

| Maintenance | Regular inspection and cleaning recommended |

How a Recirculation Valve Operates Mechanically

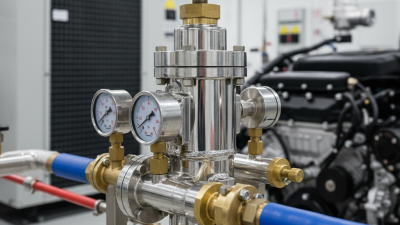

A recirculation valve is essential in various systems, helping manage fluid flow efficiently. Its mechanical operation is intricate yet fascinating. When the valve is actuated, it opens or closes a pathway for fluid. This action controls the recirculation process, ensuring a constant flow and maintaining pressure.

Mechanically, the valve uses a diaphragm or piston to operate. When pressure builds, the diaphragm flexes, prompting movement. This movement can lead to the regulated release of excess fluid. However, the calibration of these components can be tricky. If the valve is slightly miscalibrated, it can cause back pressure or sluggish flow.

Understanding the mechanics can be quite complex. Small variances in design can lead to significant performance differences. Regular inspection and maintenance are necessary to avoid inefficiencies. A minor leak or blockage can disrupt the entire system. It’s vital to grasp these details for optimal functioning.

Common Applications of Recirculation Valves in Vehicles

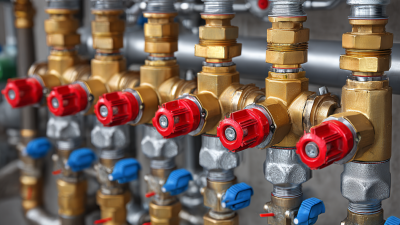

Recirculation valves play an important role in vehicles. They control the flow of air or exhaust gases, enhancing performance. These valves are essential in turbocharged engines. They help reduce turbo lag by allowing some exhaust gases to return to the intake. This process keeps the turbo spinning, providing quicker acceleration.

In vehicles equipped with superchargers, recirculation valves also shine. They prevent compressor surge, which occurs when the throttle closes suddenly. Fluid dynamics can be tricky here, but the valve regulates the pressure. A sudden change in pressure can be harmful. Many enthusiasts appreciate this component, but not everyone understands its mechanics.

Recirculation valves have other uses too. Fuel systems often utilize them to maintain optimal pressure. They can improve fuel efficiency when functioning correctly. However, if they malfunction, it can cause issues. Engine performance might suffer, leading to unexpected repairs. Balancing efficiency and reliability is crucial in these applications.

Recirculation Valve Applications in Vehicles

This bar chart illustrates the common applications of recirculation valves in vehicles, showing the percentage frequency of each application, such as engine coolant, fuel management, and turbocharger systems.

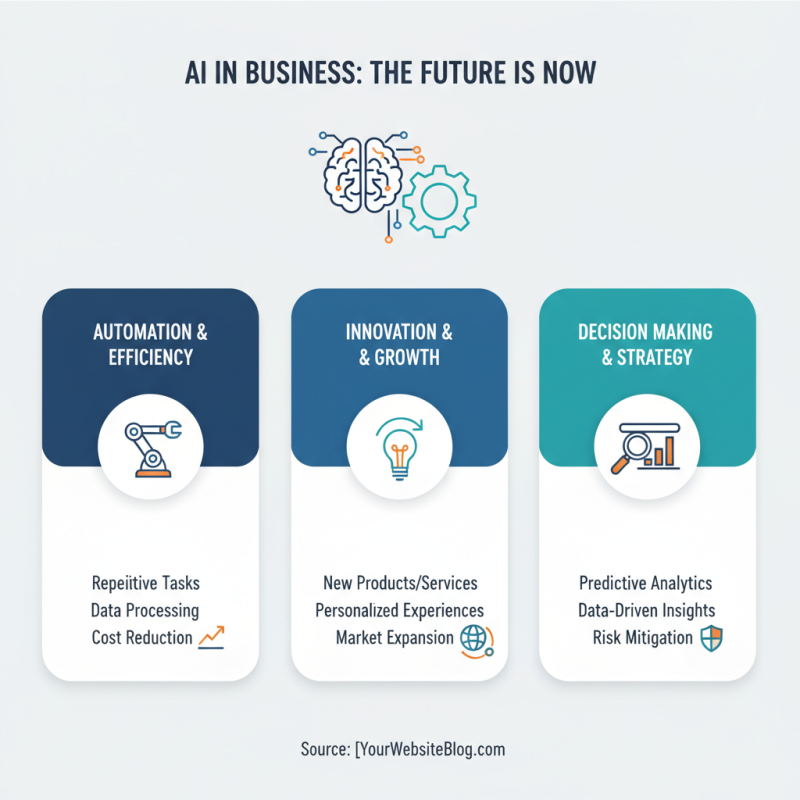

Benefits of Using Recirculation Valves in Automotive Engineering

Recirculation valves play a vital role in automotive engineering. These components regulate the flow of gases within an engine. By allowing exhaust gases to re-enter the intake system, they help improve efficiency. This process reduces emissions and enhances fuel economy. Engines with recirculation valves often perform better, especially under load.

Using recirculation valves has several benefits. They lower the combustion temperature, which can help prevent knocking. This prevents engine damage and promotes longevity. Additionally, with fewer harmful emissions, vehicles meet stricter environmental standards. Yet, it’s important to acknowledge potential downsides. Some systems may become clogged over time, reducing their effectiveness. Regular maintenance is necessary for optimal performance.

The design of these valves hinges on precise engineering. A poorly designed valve can lead to power loss. Engineers must constantly evaluate materials and performance. This is a challenge. Not every solution works for all engines. Experimentation is critical, yet not every iteration will yield success. Understanding the unique needs of each system is essential for advancement in this technology.

Related Posts

-

Top 10 Benefits of Recirculation Valve for Efficient Performance

-

Unlocking Efficiency: How Lever Valves Can Reduce Energy Consumption by Up to 30% in Industrial Applications

-

How to Choose the Right Flow Check Valve for Your Application Needs

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

How to Choose the Right Gas Valves for Your Home and Business Needs