Top 10 Important Facts About Natural Gas Shut Off Valve You Need to Know

When it comes to ensuring safety in homes or commercial properties that utilize natural gas, the natural gas shut off valve plays a crucial role. This essential component is a safety device designed to quickly stop the flow of gas in case of emergencies, such as leaks or fires. Understanding the functionality and importance of the natural gas shut off valve is vital for homeowners, renters, and maintenance personnel alike.

In this article, we will explore the top 10 important facts about the natural gas shut off valve that everyone needs to know. From its location and operation to maintenance tips and regulatory standards, having this knowledge will help ensure that you and your loved ones remain safe while using natural gas. As we delve into each fact, we will highlight how being proactive with natural gas shut off valves can prevent accidents and protect your property. Knowledge is power, and being informed about these vital safety measures is the first step towards responsible gas usage.

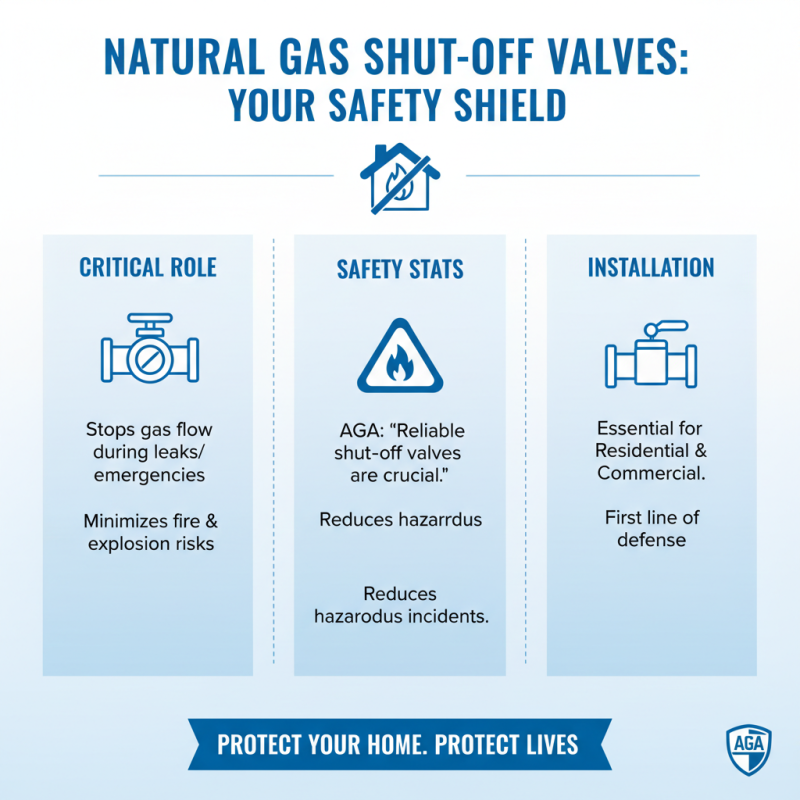

Understanding the Purpose of Natural Gas Shut Off Valves

Natural gas shut-off valves play a critical role in ensuring the safety and functionality of gas supply systems. These valves are designed to stop the flow of natural gas in the event of a leak or emergency, thereby minimizing the risk of fires or explosions. According to the American Gas Association, natural gas leaks are responsible for numerous incidents each year; thus, the presence of a reliable shut-off valve can be a crucial line of defense. Installing these valves in residential and commercial settings can significantly reduce the potential for hazardous situations.

Understanding the purpose of natural gas shut-off valves extends beyond mere safety; it also encompasses maintenance and compliance with regulatory standards. The U.S. Department of Energy reports that proper installation and regular inspections of shut-off valves can lead to improved energy efficiency and lower utility costs. In many regions, building codes require the installation of such valves, emphasizing their importance in modern construction. Homeowners and property managers alike should familiarize themselves with the functionality and proper management of these valves to ensure a safer environment and compliance with safety regulations.

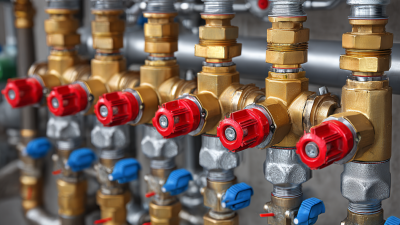

Types of Natural Gas Shut Off Valves and Their Applications

Natural gas shut off valves are critical components in the gas distribution system, ensuring safety and control over gas flow. There are several types of valves, each with unique applications. The most common types include manual shut off valves, which require physical operation to turn the gas flow on or off, and automatic shut off valves, which activate in response to certain conditions, such as a gas leak or a pressure malfunction. Additionally, there are pressure relief valves that prevent excessive pressure build-up in gas lines, providing an extra layer of safety.

When selecting a natural gas shut off valve, consider the specific application requirements. For residential settings, manual shut off valves are generally adequate for everyday use, while commercial or industrial environments may benefit from automatic options that enhance safety and efficiency. It’s also essential to ensure compatibility with existing gas systems and to follow local building codes and regulations.

Tips: Regular maintenance of natural gas shut off valves is crucial for ensuring their proper function. Check valves periodically for signs of wear or leaks, and replace them as needed. Furthermore, educating household members or employees on the location and operation of these valves can be invaluable during emergencies, ensuring a swift response if required.

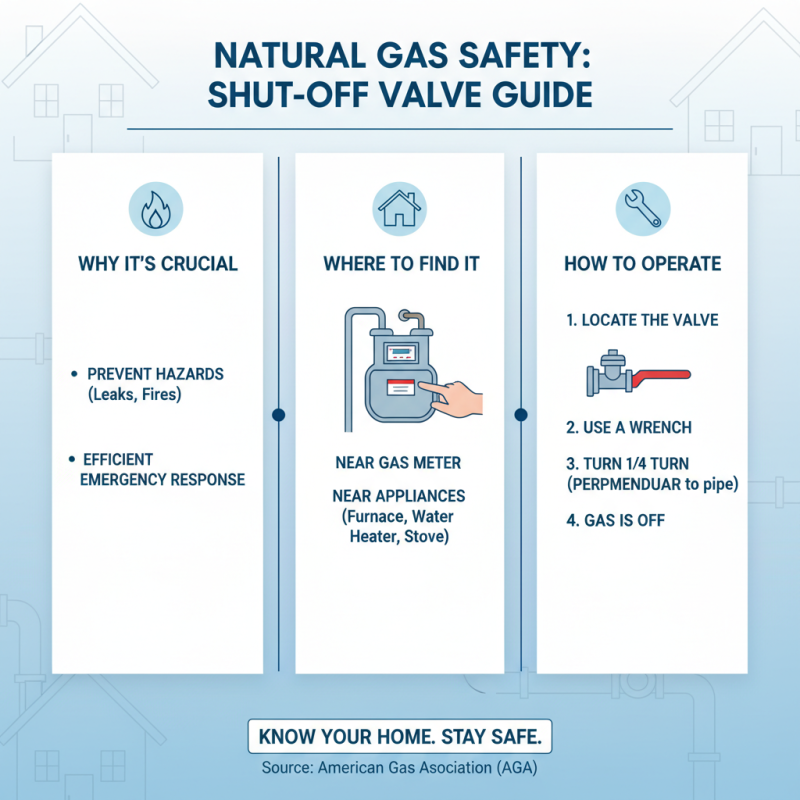

How to Operate a Natural Gas Shut Off Valve Safely

Operating a natural gas shut-off valve safely is crucial for both preventing potential hazards and ensuring efficient emergency response. According to the American Gas Association, around 22 million residential customers rely on natural gas for heating and cooking purposes. Knowing how to quickly locate and operate these valves can significantly mitigate risks associated with gas leaks or emergencies. Typically, shut-off valves are installed close to the gas meter or appliances, making it essential for homeowners to familiarize themselves with their location and functionality.

When operating a natural gas shut-off valve, always ensure your safety first. Before turning the valve, check for signs of gas leaks, such as a foul odor or hissing sounds. If you detect a leak, evacuate the area immediately and contact emergency services. To close the valve, turn it clockwise until it stops; for most valves, this means they are perpendicular to the pipe when shut. A report from the U.S. Department of Energy highlights that proper training and awareness can reduce the risks associated with gas exposure by up to 45%. Regular maintenance and inspections of gas connections can further ensure that emergencies are avoided, promoting a safer environment for all users.

Signs of a Faulty Natural Gas Shut Off Valve to Watch For

When it comes to the safety and efficiency of natural gas systems, the shut-off valve serves as a critical component. Recognizing the signs of a faulty natural gas shut-off valve is essential for homeowners and property managers alike. According to the American Gas Association, issues with shut-off valves can lead to significant safety hazards, including gas leaks that may pose serious health risks.

One common indicator of a failing shut-off valve is a noticeable drop in gas pressure, which may be detected via your gas meter. Additionally, if you smell gas near the valve or experience an unusual sound—like hissing or whistling—it may signal a critical problem. Regular inspections are recommended, as the National Fire Protection Association suggests that up to 70% of gas-related incidents could be mitigated through proper maintenance practices.

Tips: Always keep the shut-off valve accessible and educate all household members on its location and operation. If you suspect a malfunction, it is vital to act quickly. Immediate professional assistance can prevent potential accidents and ensure that your natural gas system remains safe and functional. Regularly test the function of your shut-off valve and consider installing a surveillance system to monitor any changes in gas pressure or leakage.

Maintenance Tips for Ensuring Optimal Performance of Shut Off Valves

Shut off valves are critical components in natural gas systems, ensuring safety and operational efficiency. To maintain their optimal performance, regular maintenance practices are essential. According to a report by the American Gas Association, approximately 70% of gas system failures can be traced back to inadequate valve maintenance. Therefore, routine inspections should focus on checking for leaks, corrosion, and ensuring that each valve operates smoothly under pressure.

One effective maintenance tip is to perform annual testing of shut off valves to verify their functionality. This involves opening and closing the valve to ensure it operates without obstruction. In addition, applying a suitable lubricant can prevent mechanical wear and protect against environmental factors that may cause deterioration. The U.S. Department of Energy emphasizes that such preventative measures can extend the lifespan of shut off valves, potentially reducing operational costs by 30%. Proper documentation of maintenance activities also plays a role in tracking the condition and performance of valves, allowing for timely interventions when issues arise.

Top 10 Important Facts About Natural Gas Shut Off Valve You Need to Know - Maintenance Tips for Ensuring Optimal Performance of Shut Off Valves

| Fact No. | Fact Description | Maintenance Tip | Recommended Frequency |

|---|---|---|---|

| 1 | The shut off valve is crucial for safety in gas installations. | Inspect for leaks regularly. | Every 6 months |

| 2 | Shut off valves should be easily accessible. | Ensure there are no obstructions around the valve. | Annually |

| 3 | Valves may corrode over time. | Apply a protective coating to prevent corrosion. | Every 2 years |

| 4 | Know how to turn off the gas in emergencies. | Practice emergency shut off procedures. | Quarterly |

| 5 | Check for proper valve operation once a year. | Lubricate the valve mechanism as necessary. | Annually |

| 6 | Regular maintenance can prevent costly repairs. | Schedule a professional inspection annually. | Yearly |

| 7 | There are different types of shut off valves for various applications. | Ensure the correct type is installed for your system. | As needed |

| 8 | Shut off valves need to be replaced every few years. | Know your valve's lifespan and replace as needed. | Every 5-7 years |

| 9 | Labels are important to indicate shut off valves. | Ensure valve is properly labeled. | Every 2 years |

| 10 | Training is essential for handling gas systems. | Participate in gas safety training sessions. | As available |

Related Posts

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

How to Choose the Right Flow Check Valve for Your Application Needs

-

2025's Top 5 Flow Valve Innovations You Need to Know About

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide