Top Gas Valves: Essential Types, Uses, and Buying Guide

Gas valves are essential components in various systems. They regulate the flow and pressure of gas, ensuring safety and efficiency. Understanding the types and uses of gas valves is crucial for anyone working with gas systems.

These devices come in different shapes and sizes. Some control high pressures, while others handle lower ones. Choosing the right gas valve is not always straightforward. Many factors influence the decision-making process, including pressure ratings and material compatibility.

It's vital to recognize the importance of quality in gas valves. A poorly chosen valve can lead to leaks or system failures. Reflecting on this, one should ensure to weigh all options carefully. Selecting the correct gas valve can prevent costly repairs down the line.

Essential Types of Gas Valves and Their Applications in Industry

Gas valves are crucial in various industries, controlling the flow of gas safely and efficiently. There are several essential types of gas valves, each serving different functions. One common type is the ball valve. It offers a straightforward design that provides a reliable seal. According to industry reports, around 40% of operational failures in gas systems stem from valve malfunctions. This shows the importance of choosing the right valve.

Another key type is the gate valve, widely used in pipelines. Its primary function is to fully open or close the flow. However, it is not ideal for regulating flow. Many operators mistakenly assume gate valves can control pressure. This misconception can lead to severe safety issues. Reports indicate that improper usage leads to increased maintenance costs, sometimes reaching 15% of annual operational budgets.

Lastly, butterfly valves are known for their compact design. They are suitable for large volumes of gas. However, they can suffer from wear if not properly selected. Many professionals overlook this, resulting in frequent replacements. Nearly 25% of companies report issues linked to valve selection errors. This indicates a pressing need for better education on gas valve applications and specifications in industrial environments.

Top Gas Valves: Essential Types, Uses, and Buying Guide

| Valve Type | Description | Applications | Key Features |

|---|---|---|---|

| Ball Valve | A valve with a spherical disc to control flow. | Water supply, gas pipelines, oil industries. | Quick operation, minimal flow resistance. |

| Gate Valve | A valve that opens by lifting a round or rectangular gate. | Oil and gas applications, water distribution. | Full flow with minimal obstruction, durable. |

| Globe Valve | A valve with a spherical body used to regulate flow. | Heating systems, water treatment plants. | Good throttling capability, high pressure containment. |

| Check Valve | A valve that prevents backflow in a piping system. | Pumps, compressors, process pipelines. | Automatic operation, prevents reverse flow. |

| Pressure Relief Valve | A safety device that releases pressure to prevent system failure. | Boiler systems, gas storage tanks. | Prevents overpressure, ensures safety. |

Understanding the Mechanisms: How Gas Valves Operate Safely

Gas valves play a crucial role in maintaining safety when using gas appliances. They control the flow of gas, ensuring it reaches the intended location. Understanding how gas valves operate safely is vital for anyone handling them. Basic types include manual, automatic, and solenoid valves. Each serves a unique purpose, directing gas flow precisely when needed.

When using gas valves, remember to check for leaks regularly. You can use soap and water to find bubbles indicating a leak. Closing valves when not in use is also advisable. It's easy to forget, but this simple act enhances safety.

Proper installation matters too. Incorrect setup can lead to serious issues. Take the time to review guidelines or consult a professional. It can save you from danger. Always ensure the area around the valve is clear of obstructions. This helps in maintaining safe operation and allows for easy access in emergencies.

Gas Valves Usage by Type

Key Considerations for Selecting the Right Gas Valve for Your Needs

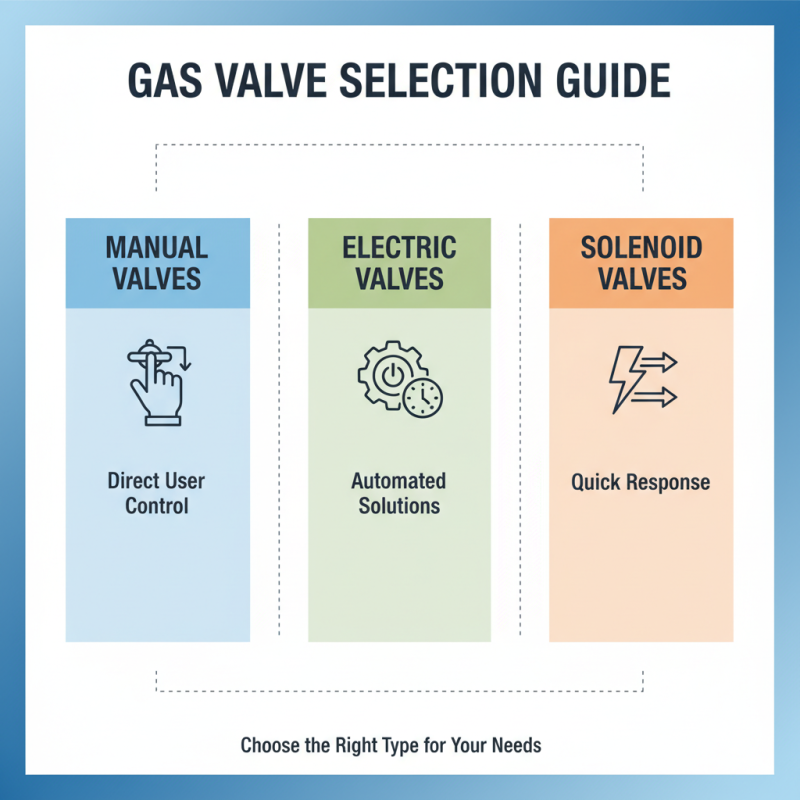

When selecting the right gas valve, several key factors need consideration. The type of valve matters significantly. Common types include manual, electric, and solenoid valves. Each has distinct functions and uses. Manual valves allow for direct user control. Electric valves offer automated solutions for convenience. Solenoid valves are ideal for quick response needs.

Another crucial aspect is the size and pressure rating of the valve. You must match these specifications to your gas system. An undersized valve can lead to pressure issues. An oversized valve may cause inefficient gas flow. Evaluate your requirements carefully. This step is often overlooked but can impact performance.

Material choice also influences durability and safety. Common materials include brass, stainless steel, and plastic. Each material serves different environments. For corrosive gases, a resistant material is essential. Think about where the valve will be used. Each decision link matters, and pondering these choices is vital. Neglecting them could lead to costly mistakes.

Industry Standards and Regulations Governing Gas Valve Usage

Gas valves play a crucial role in various industries. They regulate the flow of gas, ensuring safety and efficiency. Understanding industry standards is essential for making informed decisions. There are several regulations governing gas valve usage. These include providing guidelines on materials, design, and testing methods. Regulations can differ by region, impacting installation practices.

Standards ensure that gas valves meet safety requirements. They help prevent accidents and leaks. Common standards come from organizations focusing on public safety. Compliance with these standards is not just a legal obligation; it promotes a culture of safety. Yet, many still overlook the importance of these regulations during installations.

Choosing the right gas valve is not straightforward. Many factors, such as size and application, must be considered. It is often a learning process filled with complexities. Some users may not fully grasp the implications of poor valve choice. This can result in inefficient systems or safety hazards. Reflecting on past experiences reveals gaps in knowledge. Regular training and updates on regulations can help bridge these gaps.

Maintenance Practices for Ensuring Longevity and Safety of Gas Valves

Proper maintenance of gas valves is crucial for safety and longevity. Regular inspections can prevent leaks and malfunctions. According to industry reports, around 30% of gas-related incidents stem from faulty valves. Conducting regular checks significantly reduces these risks.

One key practice is to check for corrosion. Corroded valves can lead to dangerous leaks. Use a mild detergent to clean the exterior and ensure all connections are tight. Replace any outdated or damaged parts promptly. This helps maintain efficiency and safety.

Tips: Inspect for rust or wear every six months. Schedule maintenance annually with a certified technician.

Also, pay attention to the operational environment. Extreme temperatures or exposure to moisture can affect valve performance. Keeping valves dry and protected can extend their lifespan. Ignoring these factors can lead to costly repairs. Regular maintenance is not just wise; it’s essential for safe operations.

Related Posts

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

How to Choose the Right Gas Valves for Your Home or Business Needs

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

Top 10 Valve Home Innovations to Watch in 2025

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance