What is a Gas Shut Off Valve and How Does It Work?

A gas shut off valve is crucial in preventing gas leaks and ensuring safety in homes and businesses. Expert engineer Laura Martinez emphasizes, "A gas shut off valve is your first line of defense against potential hazards." This statement highlights the valve's importance. When a gas leak occurs, the valve can quickly stop the flow, minimizing risks.

Understanding how a gas shut off valve works is essential. These valves automatically close in emergencies, but they aren't infallible. Regular maintenance is vital to ensure they function properly. A neglected valve could fail when needed most. It's a reminder that safety measures must be routinely checked.

Incorporating a gas shut off valve in your system is a wise choice. However, relying solely on it isn't enough. Educating yourself about its operation and maintenance is equally important. Awareness can prevent dangerous situations and protect lives. Reflection on these aspects can reinforce the significance of this vital safety device.

What is a Gas Shut Off Valve?

A gas shut off valve is a critical safety feature in homes and commercial spaces. It controls the flow of natural gas or propane. When there is a gas leak or an emergency, the valve can be turned to stop the gas immediately. This quick response can prevent accidents and ensure safety.

These valves come in various types, including manual and automatic options. A manual valve typically requires a person to turn it off. In contrast, an automatic valve can detect leaks and shut off the gas without human intervention. Many people may not realize the importance of regularly checking these valves. Neglecting maintenance could lead to serious issues down the line.

In homes, gas shut off valves are usually located near the gas meter. It's essential to know where yours is and how to operate it. Some may find it challenging to access their valves due to clutter or improper placement. This can be an area for improvement. Ensuring easy access can save time in an emergency. Regularly checking your valve can foster a sense of preparedness and safety.

Types of Gas Shut Off Valves and Their Applications

Gas shut off valves are crucial for controlling the flow of gas in various applications. There are different types of these valves. The most common types include manual, automatic, and solenoid valves. Manual valves require human intervention to operate. Automatic valves, on the other hand, respond to system conditions. Solenoid valves utilize electromagnetic coils for quick actuation. Each type serves unique applications, from residential to industrial uses.

According to the American Gas Association, about 60% of residential natural gas customers rely on manual shut off valves. However, many don’t understand how to use these valves effectively. In industrial settings, automatic valves are essential for safety. They help prevent leaks and explosions by shutting off gas during emergencies. Yet, reports indicate that about 30% of gas incidents stem from malfunctioning valves. This highlights a need for better maintenance and awareness.

The choice of valve can significantly impact safety and efficiency. It’s important to assess the specific requirement of the installation site. Poor selection may lead to failures, posing risks. Training personnel on valve operation is also critical. Many systems lack proper training, leading to improper usage. This gap can have severe consequences. Each type of gas shut off valve carries its own responsibilities and risks. Careful consideration and consistent evaluation are essential.

How Does a Gas Shut Off Valve Work?

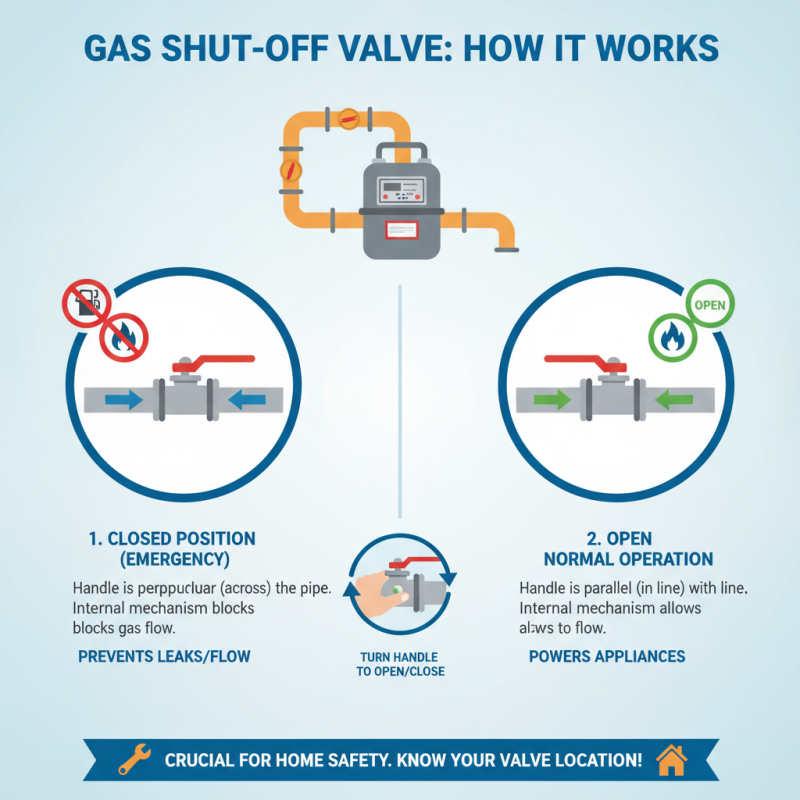

A gas shut off valve is crucial for safety in any gas system. It controls the flow of gas and can prevent leaks. But how does it work? When you turn the handle or lever, it either opens or closes the valve. In the closed position, gas cannot flow, which is vital during emergencies.

These valves come in various designs, such as ball valves or gate valves. The mechanism relies on a simple principle: a barrier that opens or closes a pathway. If a leak occurs, activating the valve quickly can mitigate potential hazards. It’s a small but powerful tool often overlooked.

Yet, many don’t understand their importance until it’s too late. Regular checks are essential. A valve not functioning correctly can lead to severe issues. It's easy to assume everything is fine, but that’s risky. Remember, safety begins with awareness and action.

Importance of Proper Installation and Maintenance

Proper installation and maintenance of gas shut-off valves are crucial for safety and efficiency. According to a recent report by the National Fire Protection Association, around 50% of home fires involve gas appliances. These numbers highlight the importance of ensuring that gas shut-off valves are correctly installed to prevent leaks and accidents.

Regular inspections can make a significant difference. A study by the American Gas Association shows that 30% of gas-related incidents can be traced back to improper valve maintenance. Checking seals and connections should be part of routine home safety checks. If you notice rust or corrosion, it may indicate a need for replacement. Ignoring such signs can lead to catastrophic failures.

Understanding the nature of gas valves is vital. These valves function similarly to a faucet, controlling gas flow to appliances. A malfunctioning valve could result in gas accumulation, posing severe risks. Regular maintenance can help detect wear early, reducing the chances of dangerous situations. Make it a habit to test these valves annually to ensure they operate smoothly.

What is a Gas Shut Off Valve and How Does It Work? - Importance of Proper Installation and Maintenance

| Feature | Description | Importance |

|---|---|---|

| Type of Valve | Two main types: manual and automatic | Ensures proper shut-off during emergencies |

| Installation Location | Near gas appliances and at the main gas line | Critical for safety and accessibility |

| Maintenance Frequency | Recommended every 6 months | Prevents leaks and malfunctions |

| Material | Common materials include brass and stainless steel | Durability and resistance to corrosion |

| Signs of Fault | Strange odors, unusual sounds, or visual leaks | Immediate action required to ensure safety |

Signs of a Malfunctioning Gas Shut Off Valve

A gas shut off valve is crucial for safety in homes. It controls the flow of gas to appliances. Knowing how it works is essential. However, a malfunctioning valve can create risks.

Signs of a malfunctioning gas shut off valve can be subtle. A sudden smell of gas is alarming. This may indicate a leak. If the valve feels unusually hot, it could signal a problem too. Inconsistent gas flow to appliances is another warning. If your stove or heater sparks issues, check the valve.

**Tips:** Regular inspection is important. Look for corrosion or physical damage. When in doubt, consult a professional to assess the valve. It's better to be safe than sorry. Keep your space ventilated. Always prioritize safety over convenience. Act when you notice these signs. Ignoring can lead to severe consequences.

Gas Shut Off Valve Performance Statistics

This bar chart represents the performance and common issues encountered with gas shut off valves, based on various observed parameters such as frequency of malfunctions and response time during tests.

Related Posts

-

10 Essential Tips for Locating and Operating Your Natural Gas Shut Off Valve

-

Best Home Valves for Energy Efficiency in 2023 Based on Industry Data

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

How to Choose the Best Ball Valve Manufacturers for Your Needs?

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Top 10 Important Facts About Natural Gas Shut Off Valve You Need to Know