What is the Function of Saunders Valves in Fluid Control Systems?

Fluid control systems utilize various components to ensure effective operation. One such vital component is the saunders valve. These valves play a crucial role in managing fluid flow in different applications, from industrial processes to water treatment.

Saunders valves are designed for specific tasks. They can regulate flow, control pressure, and manage system efficiency. In many cases, efficiency can be compromised if the wrong valve is selected. The choice of a saunders valve should consider factors like media type and operating conditions. Yet, many systems still face challenges due to improper valve selection.

Understanding the full function of saunders valves is essential for engineers and operators. Their unique design provides advantages, but mistakes can lead to leaks or failures. Reflecting on these issues helps improve overall system reliability. It also underscores the importance of selecting the right valve for each situation.

Overview of Saunders Valves and Their Design Features

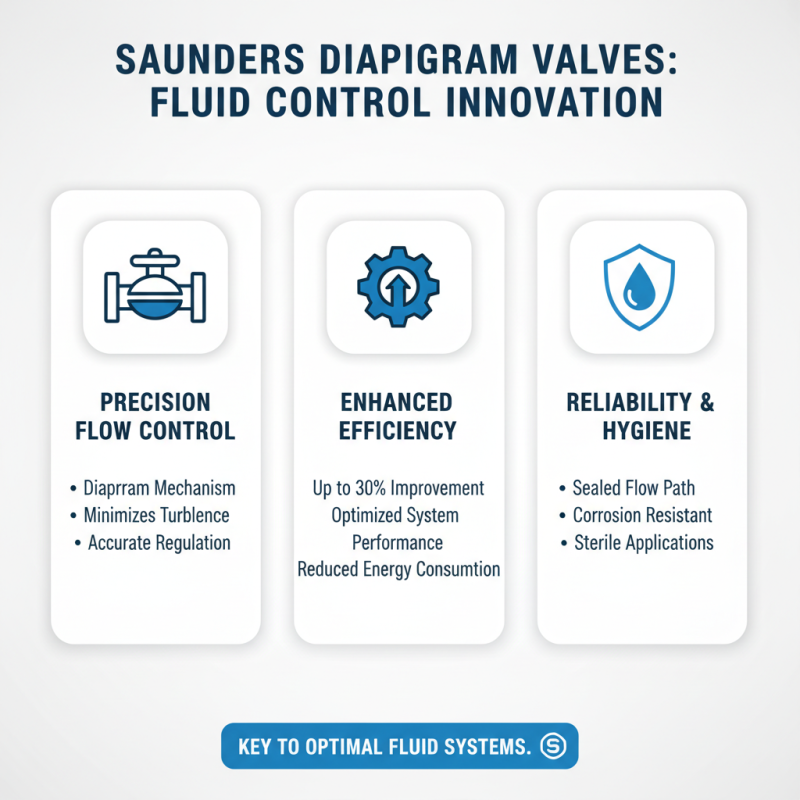

Saunders valves play a critical role in fluid control systems. Their unique design features include a diaphragm mechanism. This mechanism allows for precise control of fluid flow while minimizing turbulence. According to industry reports, fluid control systems can see improvements in efficiency by up to 30% with the right valve selection.

The valve's body is often constructed from durable materials like polypropylene. This enhances longevity and resistance to corrosion, particularly in harsh environments. Studies show that these materials can withstand extreme temperatures, making them ideal for various applications. The user-friendly design also facilitates easy maintenance, which is crucial for continuous operation.

However, not all installations go smoothly. Improper sizing or installation can lead to leaks or inefficient operation. A review highlighted that nearly 15% of fluid control systems experience failures due to valve issues. Regular assessments and adjustments are necessary to optimize performance. Understanding the specific design features of Saunders valves can help mitigate these risks, ensuring better fluid control and system reliability.

Types of Saunders Valves Used in Fluid Control Systems

Saunders valves are essential in fluid control systems. They come in various types, each serving specific applications. Common types include diaphragm valves, pinch valves, and check valves. Diaphragm valves use a flexible membrane. This allows for precise flow control. They are often used in the pharmaceutical and food industries. Their design reduces contamination, which is crucial for safety.

Pinch valves have a simple mechanism. They consist of a rubber tube that is pinched to stop flow. This design is effective for slurries or viscous fluids. They are reliable and easy to maintain. However, they may wear out over time. Users must monitor their condition regularly.

Check valves are crucial for preventing backflow. They allow fluid to flow in one direction only. These valves are vital in various systems, including water supply and drainage. They help protect pumps and other equipment from damage. Maintenance can be a challenge, though. Users should periodically check for clogs or leaks. Different types have strengths and weaknesses. Understanding these can lead to better fluid system design.

What is the Function of Saunders Valves in Fluid Control Systems? - Types of Saunders Valves Used in Fluid Control Systems

| Type of Valve | Function | Application | Material |

|---|---|---|---|

| Rubber Lined Saunders Valve | Allows smooth flow control and shut-off | Slurry handling in mining and mineral processing | EPDM, Nitrile |

| Plastic Saunders Valve | Corrosion resistant, used for aggressive fluids | Chemical processing and waste management | PVC, PP |

| Metal Saunders Valve | High pressure tolerance and durability | Oil and gas industry | Stainless steel, Carbon steel |

| PTFE Lined Saunders Valve | Excellent chemical resistance and low friction | Pharmaceutical and food processing | PTFE |

Operating Principles of Saunders Valves in Fluid Dynamics

Saunders valves play a crucial role in fluid control systems, particularly in regulating flow and pressure. These valves are designed based on a specific operating principle that leverages their unique structure. When activated, the valve creates a mechanical seal that effectively controls the flow of liquids or gases. This process relies on the valve body's geometric configuration, ensuring minimal turbulence and efficient flow rates. Data indicates that well-designed valves can improve system efficiency by up to 25%.

In fluid dynamics, the operating principles of Saunders valves highlight their adaptability. They can handle various fluid types, including slurries and corrosive substances. The materials used in their construction are essential. Advanced composites and metal alloys typically offer better resistance to wear and corrosion. Moreover, the simplicity of their design can lead to maintenance challenges. Incorrect handling may result in premature failure, affecting system reliability and performance.

Despite their advantages, the operational efficiency of Saunders valves needs regular assessment. Factors like pressure variations and temperature changes can influence their effectiveness. Organizations should monitor these parameters to ensure optimal performance. Adapting to changing conditions is necessary, but it can be daunting. Understanding the underlying principles can aid in decision-making, helping to avoid potential pitfalls in fluid control systems.

Applications of Saunders Valves in Various Industries

Saunders valves play a crucial role in various fluid control systems across industries. In pharmaceutical applications, these valves ensure precise flow control. They are often utilized in processes that require stringent hygiene standards. Their design minimizes dead space, making cleaning easier. However, during manufacturing, some valves may require frequent maintenance. This adds to operational costs.

In the food and beverage industry, Saunders valves help maintain product integrity. They control the flow of liquids without introducing contaminants. This is essential for quality assurance. Yet, not all facilities are equipped to handle their maintenance needs. Some operations experience breakdowns, which could lead to product loss.

Chemical processing is another area where Saunders valves are indispensable. These valves manage corrosive substances efficiently. Their rugged construction withstands harsh environments. However, compatibility issues with certain chemicals must be addressed. Using the wrong materials can lead to system failures. Awareness of these challenges is critical for safe operation.

Application of Saunders Valves in Various Industries

Benefits of Using Saunders Valves in Fluid Control Solutions

Saunders valves play a crucial role in fluid control systems.

These valves manage the flow of liquids and gases efficiently. They are designed to handle a variety of pressures

and temperatures, making them versatile for many applications. Common uses include chemical processing

and water treatment.

Benefits of using Saunders valves include superior sealing capabilities.

They minimize leaks, which is essential for preventing contamination. These valves also offer easy maintenance.

Many designs allow for quick access for repairs or replacements. This feature saves time and money in the long run.

Tips: Always inspect valves regularly.

Look for signs of wear or corrosion. Regular checks can prevent unexpected failures.

Use the right valve for your specific application. Mismatched valves may lead to suboptimal performance.

Consider the environment and fluid types mentioned in the system's design.

Related Posts

-

How to Choose the Right Pilot Valve for Your Application?

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Top 10 Saunders Valves Benefits You Should Know

-

Top 10 Tips for Choosing the Best Valve Suppliers for Your Projects