How to Choose the Right Valve for Your Plumbing Needs?

Choosing the right valve for your plumbing needs can feel overwhelming. Numerous options are available, and understanding each is crucial. A single valve can impact your entire plumbing system. Selecting the wrong one may lead to leaks or insufficient water flow.

Take, for example, a standard ball valve and a gate valve. They both control water flow, yet their mechanisms differ. A ball valve provides a tight seal, ideal for shut-off applications. Meanwhile, a gate valve excels in regulating flow, but it may not seal as well. Such differences illustrate the importance of understanding your requirements.

Remember, it’s easy to overlook specifics. You might prioritize cost over quality, risking future issues. Each valve serves a unique purpose, and neglecting this can lead to frustration. Assess your plumbing system carefully. Evaluating options, ensuring compatibility, and acknowledging potential pitfalls are vital steps. A well-chosen valve can enhance your plumbing experience significantly.

Factors to Consider When Selecting a Valve for Plumbing Applications

When selecting a valve for plumbing applications, several important factors should be considered. First, it's essential to understand the type of fluid flowing through the system. Is it water, gas, or something else? Each fluid type has specific valve requirements. According to industry reports, nearly 70% of plumbing failures arise from improper valve selection. This highlights the need for careful consideration.

Material choice is another critical factor. Valves made from brass or stainless steel are durable and corrosion-resistant. However, they may be costlier than plastic options. The right material ensures longevity and efficiency in your plumbing system. Assess the temperature and pressure ratings of the valve as well. Each valve has its limits. Exceeding these may lead to leaks or failure.

**Tips:** Always check compatibility with existing plumbing materials. A mismatched valve can cause serious issues over time. Pay attention to installation spaces and maintenance access as well. Not all valves are easy to reach once installed. Remember to evaluate your long-term plumbing needs too. What works now might not be suitable in the future.

How to Choose the Right Valve for Your Plumbing Needs? - Factors to Consider When Selecting a Valve for Plumbing Applications

| Valve Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Application |

|---|---|---|---|---|

| Ball Valve | Brass | 600 | -20 to 200 | Water, Gas |

| Gate Valve | Cast Iron | 250 | -10 to 150 | Water, Sewage |

| Globe Valve | Stainless Steel | 300 | -50 to 400 | Oil, Gas |

| Check Valve | PVC | 150 | 32 to 140 | Water |

| Butterfly Valve | Aluminum | 200 | -40 to 250 | HVAC, Water |

Types of Valves Commonly Used in Plumbing Systems

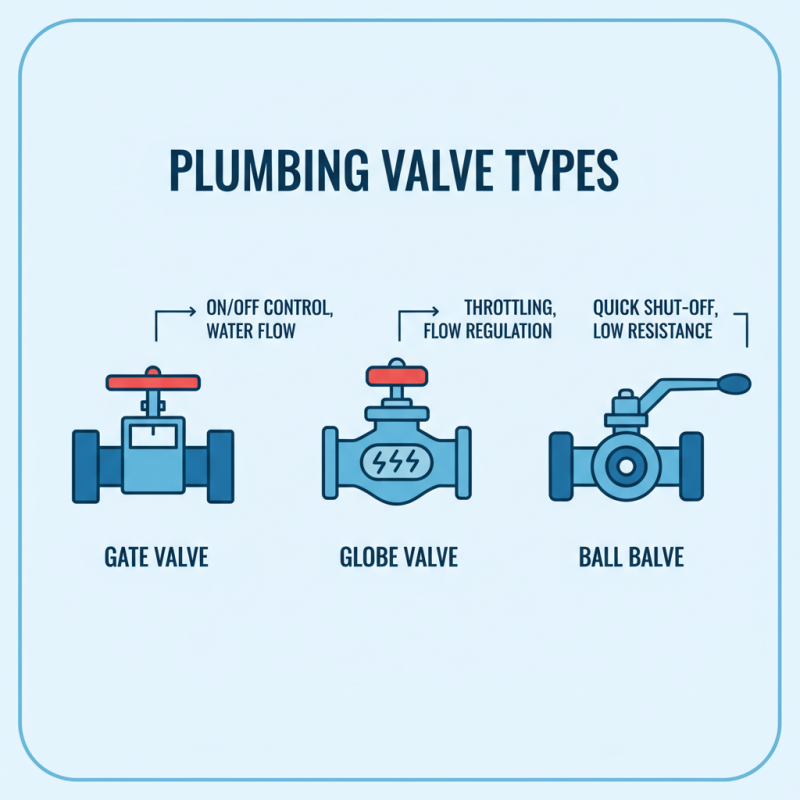

When selecting a valve for plumbing, it’s important to know the types available. Common valves include gate valves, globe valves, and ball valves. Each type serves specific purposes. Gate valves are great for on/off control, ideal for water flow regulation. Globe valves provide better throttling ability. They can restrict flow more efficiently compared to others. Ball valves, on the other hand, are perfect for quick shut-off. Their design allows for minimal flow resistance.

Consider using gate valves in outdoor applications. They often handle larger volumes. Globe valves can be used in heating systems. They're not as common but can be quite effective in specific setups. For most household tasks, ball valves work well. They are easy to operate and maintain.

Tips: Always consider the pressure ratings. Ensure they match your plumbing system. A mismatch can lead to leaks or failure. Check materials too. Copper, PVC, and brass are common choices. Each type has different longevity and suitability. Avoid rushing into a decision. Take time to reflect on your needs. A thoughtful choice will save you trouble later.

Understanding Valve Specifications and Ratings

When selecting a valve for plumbing needs, understanding specifications and ratings is crucial. Valves control flow, pressure, and direction within a system. Material is one of the first elements to consider. Brass and stainless steel are common choices. They offer durability and corrosion resistance. However, the right material depends on the specific application.

Pressure rating is another critical aspect. It indicates how much pressure a valve can handle. Look for the maximum pressure rating that matches your plumbing requirements. A mismatch can cause leaks or breakage. Pay attention to temperature ratings as well. High temperatures can alter material properties, affecting performance.

Finally, usability features also matter. Some valves are easier to operate than others. Consider whether you need manual or automatic operation. The size and connection type can also influence the installation process. It’s easy to overlook these details, but doing so can lead to frustration later. Ensure you review specifications carefully before making a decision.

Installation Guidelines for Different Valve Types

When selecting a valve for your plumbing system, installation guidelines are crucial. Different valve types, such as gate, globe, and ball valves, have unique installation requirements. For instance, ball valves require a straight alignment with the pipeline. Misalignment can lead to leaks and operational issues.

According to industry reports, improper installation leads to 30% of all plumbing failures. It's vital to ensure the valve is oriented correctly. Tightening should be done gradually. Over-tightening can damage the valve and joints. Many professionals recommend using a torque wrench for accuracy.

Also, consider the valve's material. Brass and stainless steel are commonly used for durability. Proper sealing is essential. Teflon tape or thread sealant should be applied to threaded connections. This prevents leaks and prolongs valve life. Keep in mind, not all valves perform well under high pressure. Research helps avoid costly mistakes.

Valve Types Used in Plumbing

This chart demonstrates the popularity of various valve types used in plumbing systems. Ball valves are the most commonly used, accounting for 40% of applications, followed by gate valves at 25%. Other valves like globe, check, and butterfly valves also serve important roles but are less common.

Maintenance Tips for Ensuring Valve Longevity and Performance

When it comes to plumbing valves, maintenance is key. Regular checks can prevent larger issues down the line. For instance, inspect the valve body for signs of corrosion or leakage. A few drops can mean something serious. It's wise to tighten any loose fittings immediately. Moreover, replacing old valves can save water and reduce bills.

Another crucial aspect is proper lubrication. Many valves require specific lubricants to function smoothly. Dry valves tend to stick, leading to potential malfunctions. It’s easy to forget lubrication, but it’s essential for performance. Use a gentle approach when applying, as too much can cause blockage.

Don't overlook temperature changes. Extreme heat or cold can affect valve function. Insulating your pipes may prevent damage. Regularly flushing out your system can also help avoid buildup. Pay attention to how your valves react seasonally. Sometimes, a little observation can highlight underlying problems before they escalate. Keeping a maintenance schedule can be difficult, but it is necessary for longevity.

Related Posts

-

Top 10 Benefits of Recirculation Valve for Efficient Performance

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

Top 10 Saunders Valves Benefits You Should Know

-

2025 How to Choose the Best Valve Products for Your Industry Needs

-

How to Choose the Right Combination Valve for Your Plumbing System

-

Top 10 Gate Valves Types and Their Best Applications for Your Projects