How to Choose the Right Gas Valves for Your Home or Business Needs

Choosing the right gas valves is crucial for both residential and commercial settings, as these essential components ensure the safe and efficient operation of gas systems. Gas valves control the flow and pressure of gas, making them integral to heating, cooking, and numerous industrial processes. When selecting gas valves, it is important to consider various factors such as the type of gas being used, the valve's pressure rating, material compatibility, and operational requirements. Understanding these aspects can help you make informed decisions that prioritize safety and performance.

Additionally, the application environment plays a significant role in the selection process. Whether for a home kitchen, a heating system, or an industrial application, the right gas valve must meet specific demands and regulations. This not only helps prevent potential hazards but also ensures optimal functionality. As we delve into the process of selecting the appropriate gas valves, we will explore key aspects to consider, allowing you to navigate the options available with confidence and clarity. Through careful evaluation, you can enhance safety, efficiency, and reliability in your gas installations.

Factors to Consider When Selecting Gas Valves

When selecting gas valves for residential or commercial applications, several critical factors must be considered to ensure safety, efficiency, and compliance with industry standards. One of the primary aspects is the specific type of gas being handled, as different gases can have varying properties that affect valve suitability. According to a report by the Gas Technology Institute, natural gas, propane, and butane each require valves designed to withstand unique pressure and temperature conditions. For instance, valves used for high-pressure applications need to be constructed from materials that can handle increased stress without compromising performance.

Another significant consideration is the valve's pressure rating. The American Society of Mechanical Engineers (ASME) provides guidelines indicating that selecting a valve with a pressure rating that exceeds the maximum expected operating pressure can prevent catastrophic failures. This is particularly crucial in settings like restaurants or industrial kitchens, where the demand for gas is high and consistent. Furthermore, the size of the valve should be appropriate for the gas line's diameter to maintain optimal flow and prevent blockages, which can lead to inefficiency and safety hazards. Regularly consulting industry reports and adhering to local regulations will also aid professionals in making informed choices, ultimately enhancing the safety and reliability of gas systems in any environment.

Gas Valves Selection Criteria

Understanding the key factors when selecting gas valves for your home or business needs.

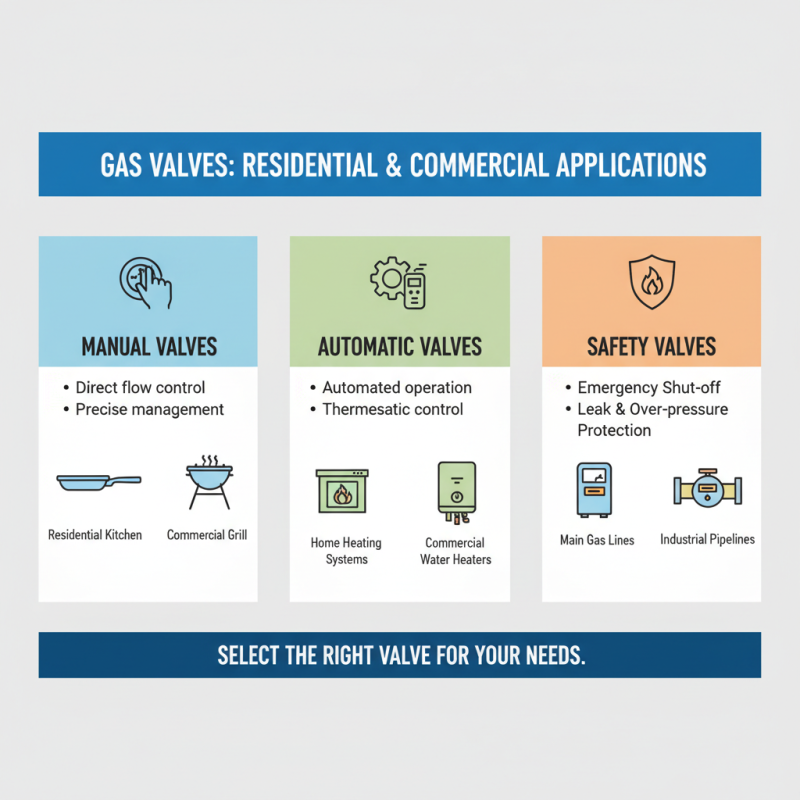

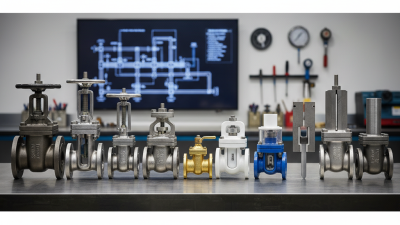

Types of Gas Valves Suitable for Residential and Commercial Use

When selecting gas valves for residential or commercial use, it's essential to understand the various types available and their specific applications. The most common types of gas valves include manual valves, automatic valves, and safety valves. Manual gas valves allow users to control the flow of gas directly, making them ideal for areas where precise management of gas usage is necessary, such as in a residential kitchen or a commercial grill.

On the other hand, automatic gas valves provide enhanced convenience and safety, as they can be controlled remotely or automatically shut off during emergencies. These valves are particularly beneficial in commercial applications where gas equipment runs continuously, such as in industrial kitchens or manufacturing facilities. Additionally, safety valves are critical components that help prevent over-pressurization and protect against leaks, ensuring a secure environment for both home and business operations. Choosing the right valve type based on your specific needs will enhance safety and efficiency in managing gas systems.

Understanding Gas Pressure Ratings and Their Importance

When selecting gas valves for your home or business, understanding gas pressure ratings is crucial for safety and efficiency. Gas pressure ratings indicate the maximum amount of pressure a valve can handle without compromising its integrity. These ratings are generally categorized into low, medium, and high-pressure systems.

Low-pressure valves are typically used in residential applications where the gas demand is lower, while high-pressure valves are essential for industrial settings that require greater volumes of gas to function effectively.

Properly matching the right valve to the corresponding pressure rating is vital. Using a valve with an insufficient pressure rating can lead to leaks, system failures, or even hazardous situations. It is also important to consider the specific requirements of your gas system, such as the type of gas being used and the operating conditions.

By carefully evaluating these factors, you can ensure that you select the best gas valve that not only meets legal safety standards but also enhances the functionality of your gas system.

Material Compatibility of Gas Valves with Different Gas Types

When selecting gas valves for residential or commercial purposes, understanding the

material compatibility of gas valves with various gas types is crucial. Different gases,

such as natural gas, propane, and butane, have unique

chemical properties that can affect the integrity of the valve materials over time. According to the

American National Standards Institute (ANSI), using the right materials is essential to prevent leaks and ensure

safety in gas delivery systems.

For instance, brass is commonly used for natural gas applications due to its

resistance to corrosion and ability to withstand high pressures. However, it may not be suitable for environments

involving hydrogen, which can embrittle brass, leading to potential

failures. On the other hand, stainless steel performs well across a wider

range of gases and is resistant to rust and degradation, making it a reliable choice for many

industrial applications. Research from the Gas Technology Institute indicates that using

the correct valve material can enhance system longevity and significantly reduce maintenance costs over time.

Tips: Always consult the gas valve specifications and

compatibility charts supplied by industry standards to ensure the materials you choose meet the requirements for

the specific type of gas being used. Additionally, consider environmental factors such as temperature and exposure

to chemicals, as these can influence material performance and lifespan. Regular inspections also help identify

potential material degradation before it leads to serious issues.

Installation and Maintenance Tips for Optimal Performance

When it comes to gas valve installation, ensuring optimal performance should be a priority. Start by assessing the specific needs of your home or business. Select a valve that matches your system's pressure requirements and type of gas. Proper sizing is critical; an oversized valve can lead to inefficiencies, while an undersized valve may restrict flow, creating dangerous situations. Always work with valves designed for the specific application, whether for heating systems, appliances, or industrial processes.

Maintenance is equally important for ensuring the longevity and safety of gas valves. Regular inspections should be conducted to check for signs of wear, leaks, or corrosion. It’s crucial to ensure that all connections are tight and that seals are intact. Cleaning the valve components periodically can prevent buildup that may affect performance. If you notice any irregularities or performance issues, consult a professional to address potential problems before they escalate. Establishing a routine maintenance schedule can significantly enhance efficiency and reliability, providing peace of mind in gas management.

Related Posts

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

Top 10 Gate Valves Types and Their Best Applications for Your Projects

-

Top 10 Valve Home Innovations to Watch in 2025

-

How to Choose the Right Flow Check Valve for Your Application Needs

-

2025 How to Choose the Best Valve Products for Your Industry Needs