How to Choose the Right Gas Valves for Your Home and Business Needs

Choosing the right gas valves for your home or business is a crucial decision that can significantly impact safety and efficiency. Gas valves are essential components in any system that utilizes gas for heating, cooking, or powering appliances. With various types and specifications available on the market, it can be daunting to select the appropriate gas valves that meet your specific needs.

In this guide, we will explore the key factors to consider when choosing gas valves, including the type of gas used, the pressure requirements, and the environment where the valves will be installed. Understanding these elements will not only ensure optimal functionality but also provide peace of mind regarding safety. Whether you are a homeowner looking to retrofit your kitchen or a business owner in need of industrial solutions, equipping yourself with the right knowledge about gas valves will empower you to make informed decisions.

Stay tuned as we delve into practical advice and tips that will help you navigate through the selection process, ensuring that you find the perfect gas valves tailored for your unique requirements.

Choosing the Right Gas Valves: Understanding Pressure Ratings and Flow Capacities

When selecting gas valves for home and business applications, understanding pressure ratings and flow capacities is crucial. According to the American National Standards Institute (ANSI), gas valves are classified based on their pressure ratings, typically ranging from ½ psi for residential use to over 50 psi for industrial applications. This classification aids in ensuring the safety and efficiency of gas systems, as using a valve with an inadequate pressure rating can lead to system failures or hazardous leaks.

Flow capacity is another essential factor to consider. The Gas Research Institute (GRI) suggests evaluating the cubic feet per hour (CFH) requirements of your appliances to determine the right valve size. For instance, a typical household gas water heater may require a flow capacity of approximately 100 CFH, while commercial cooking equipment might demand significantly higher rates. Choosing a gas valve that meets or exceeds these CFH requirements will help maintain optimal performance and safety in gas distribution systems, ultimately enhancing the reliability of your appliances.

Key Industry Standards: ANSI, API, and Their Importance in Gas Valve Selection

When selecting gas valves for your home or business, understanding key industry standards such as ANSI (American National Standards Institute) and API (American Petroleum Institute) is essential. These standards ensure the safety, reliability, and efficiency of gas valves, making them crucial for effective gas flow management. According to a recent report by the Global Gas Valve Market, adherence to ANSI standards is linked to increased operational safety, reducing potential hazards by up to 30%. In contrast, API standards specifically address the needs of the oil and gas sector, reinforcing the structural integrity and performance capabilities of valves under high-pressure conditions.

Tips for selecting gas valves include consulting with industry professionals to determine the specific requirements of your application. Whether you need a valve for a commercial kitchen or an industrial operation, ensure that the selected valve complies with the relevant ANSI or API standards. Furthermore, consider factors such as pressure rating, gas type, and environmental conditions to ensure optimal valve performance.

Another important tip is to regularly review equipment maintenance schedules in line with industry best practices. A report by the National Association of Corrosion Engineers indicates that proactive maintenance can extend the lifespan of gas valves by up to 50%. This approach not only ensures safety but also enhances the overall efficiency of gas systems in both residential and commercial settings.

Gas Valve Selection Standards and Popularity

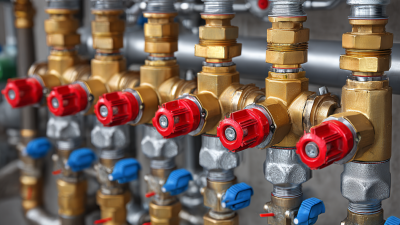

Assessing Application Requirements: Residential vs. Commercial Gas Valve Specifications

When selecting gas valves for residential versus commercial applications, understanding their specific requirements is crucial. Residential gas valves typically need to accommodate lower pressure settings and are designed for standard home appliances such as stoves, heaters, and water heaters. These valves prioritize safety features like over-pressure protection and easy shut-off mechanisms, as they operate in an environment where user accessibility and safety are paramount.

Conversely, commercial gas valves must handle higher pressures and larger flows to support equipment like industrial boilers and commercial kitchens. These valves often feature more rugged construction to endure frequent use and higher gas volumes. Additionally, they may require advanced control systems to integrate with more complex setups, ensuring regulatory compliance and optimal performance in a bustling business environment. Understanding these distinctions will guide users in selecting the right gas valve products tailored to their specific operational needs.

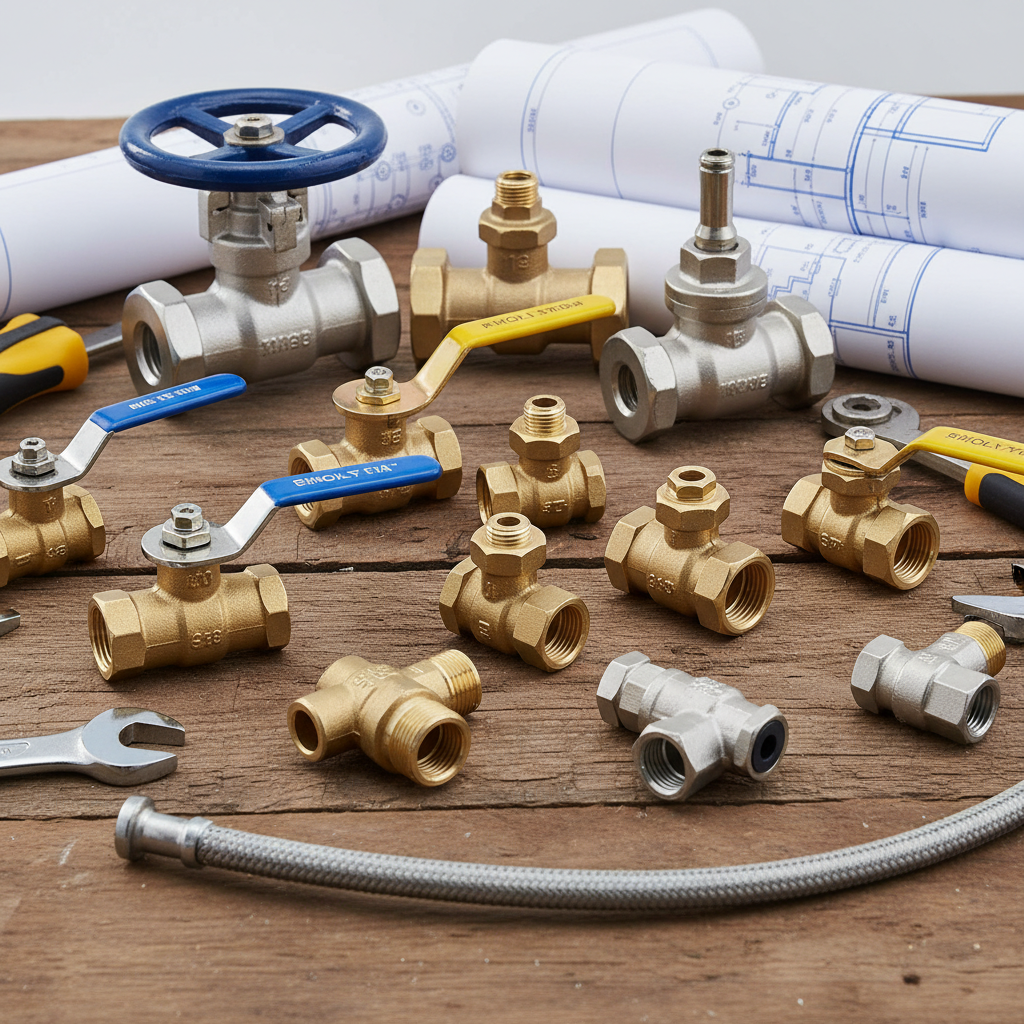

Material Selection: Comparing Brass, Stainless Steel, and Plastic Gas Valves

When selecting gas valves for your home or business, the choice of material is crucial for safety and efficiency. Brass, stainless steel, and plastic are three common materials used in gas valves, each with its unique properties and applications. According to a report from the National Institute of Standards and Technology (NIST), brass valves are known for their excellent corrosion resistance and durability, making them ideal for residential use. They can withstand high temperatures and pressures, which ensures long-term performance in standard gas applications.

On the other hand, stainless steel valves are favored in industrial settings due to their superior strength and resistance to aggressive chemicals. A study published by the American Society of Mechanical Engineers (ASME) highlighted that stainless steel valves can better handle corrosive environments, which is essential in commercial facilities involving harsh working conditions. Furthermore, plastic gas valves are increasingly being used for lighter applications where weight and cost are considerations. The Plastics Industry Association (PIA) has indicated that while plastic valves are generally less durable than metal counterparts, advancements in material technology have significantly improved their performance in non-critical applications. Each of these materials offers distinct advantages, and understanding these differences is vital for making an informed decision based on your specific needs.

How to Choose the Right Gas Valves for Your Home and Business Needs

| Material | Durability | Corrosion Resistance | Temperature Resistance | Cost |

|---|---|---|---|---|

| Brass | High | Moderate | Up to 200°C | Medium |

| Stainless Steel | Very High | High | Up to 600°C | High |

| Plastic | Moderate | Low | Up to 90°C | Low |

Safety Features in Gas Valves: Understanding the Importance of Automatic Shut-off Mechanisms

Automatic shut-off mechanisms in gas valves are crucial for ensuring the safety of both residential and commercial environments. These mechanisms serve as a first line of defense against potential hazards such as gas leaks, which can lead to catastrophic incidents, including fires and explosions. Recent advancements in safety valve technology highlight the importance of such features. For example, innovations in industrial safety valves demonstrate how quickly these automatic shut-off systems can respond—often within one to five seconds—preventing the leakage of combustible gases and significantly enhancing overall plant safety.

The growing emphasis on safety regulations across multiple industries underscores the necessity of incorporating automatic shut-off valves into gas management systems. A failure to implement these technologies can result in severe consequences, as improper management of gas systems can provoke disastrous events. Historical incidents, such as gas leaks triggered by equipment malfunctions, have shown the critical nature of robust safety systems. Therefore, as individuals and businesses look to select the right gas valves, prioritizing options that feature reliable automatic shut-off mechanisms is essential for safeguarding their operations and ensuring a secure environment.

Related Posts

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

Best Home Valves for Energy Efficiency in 2023 Based on Industry Data

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance