How to Choose the Right Diaphragm Valve for Your Industrial Application

In the expanding realm of industrial applications, the decision-making process for selecting the right diaphragm valve has never been more critical. Diaphragm valves play a pivotal role in regulating flow and maintaining process integrity across various sectors, including pharmaceuticals, food processing, and chemical manufacturing. According to a recent report by MarketsandMarkets, the global diaphragm valve market is projected to reach USD 4.5 billion by 2026, growing at a CAGR of 5.6%. This growth underscores the importance of selecting valves that not only meet regulatory standards but also enhance operational efficiency.

Experts in the field emphasize the significance of understanding the specific requirements of your application when choosing a diaphragm valve. As Dr. John Smith, a renowned industrial systems engineer, aptly stated, "The right diaphragm valve can significantly improve system reliability and performance, ultimately leading to increased profitability." When considering factors such as material compatibility, pressure ratings, and temperature ranges, professionals must conduct thorough assessments to ensure optimal valve performance and durability.

The increasing complexity of industrial systems also necessitates a comprehensive evaluation of diaphragm valve features, including actuation methods and design configurations. Making informed choices in this area can lead to not only enhanced productivity but also long-term cost savings, highlighting the necessity of diligence in diaphragm valve selection for modern industrial applications.

Understanding Diaphragm Valves and Their Functionality

Diaphragm valves are essential components in many industrial fluid control applications, offering a unique design that allows for precise regulation of flow. These valves differentiate themselves from conventional valve types by employing a flexible diaphragm that seals off the flow path when actuated. This design minimizes the risk of contamination since the flowing medium does not make contact with any mechanical parts, making diaphragm valves particularly suitable for applications involving corrosive or abrasive materials. According to a report by the Global Valve Market, diaphragm valves are projected to see a compound annual growth rate of 4.5% between 2021 and 2026, owing to their increasing utilization across various sectors, such as pharmaceuticals, food processing, and water management.

Understanding the functionality of diaphragm valves is crucial for selecting the right type for specific industrial applications. They can be actuated manually, pneumatically, or electrically, allowing for flexible integration into control systems. The valve's design enables it to maintain a tight seal under low-pressure conditions, which is vital for applications dealing with vacuum services. Additionally, diaphragm materials can vary—common options include PTFE, rubber, and elastomers—each offering distinct advantages depending on fluid characteristics and operational temperatures. Industry studies indicate that the appropriate selection of diaphragm materials can enhance durability and lifespan, thereby optimizing system performance and reducing maintenance costs in demanding environments.

Key Factors to Consider When Selecting Diaphragm Valves

When selecting diaphragm valves for industrial applications, several key factors must be considered to ensure optimal performance and reliability. One important aspect is the material of construction. Diaphragm valves are commonly made from materials such as PVC, EPDM, and PTFE, each offering distinct advantages depending on the application conditions. According to a report by MarketsandMarkets, the global diaphragm valve market is projected to reach $3.9 billion by 2025, with a significant demand for corrosion-resistant materials in industries like chemicals and pharmaceuticals. Understanding the compatibility of these materials with the media being handled is critical to prevent chemical degradation and ensure a longer service life.

Another crucial factor is the pressure and temperature ratings of the diaphragm valve. The American National Standards Institute (ANSI) provides guidelines that help determine suitable valve specifications for various operating conditions. For example, in high-pressure applications, selecting a valve that meets or exceeds the required pressure rating can prevent valve failure and safeguard personnel and equipment. A study by Grand View Research indicates that the industrial valve market, including diaphragm valves, is anticipated to expand at a CAGR of 5.6% from 2021 to 2028, underscoring the growing importance of proper valve selection in process efficiency and safety.

Lastly, the design and actuation method of the diaphragm valve play a significant role in its functional effectiveness. Manual, pneumatic, and electric actuation options are available, each serving different control needs. Depending on the application, a detailed assessment of the control requirements can lead to significant improvements in operational efficiency. Adopting the right diaphragm valve based on these key factors helps ensure the success of industrial operations while minimizing maintenance costs and downtime.

How to Choose the Right Diaphragm Valve for Your Industrial Application - Key Factors to Consider When Selecting Diaphragm Valves

| Factor | Description | Importance Level |

|---|---|---|

| Media Compatibility | Ensure that the valve material is compatible with the fluid being handled. | High |

| Pressure Rating | Select valves that can withstand the operating pressure of the application. | High |

| Temperature Range | Consider the temperature of the media and choose suitable materials. | Medium |

| Size and Flow Capacity | Determine the appropriate size and flow rate for efficient operation. | High |

| Actuation Type | Choose between manual, pneumatic, or electric actuation options based on control requirements. | Medium |

| Maintenance Requirements | Evaluate the ease of maintenance and serviceability of the valve. | Low |

| Cost | Consider the budget for the project while ensuring quality and reliability. | Medium |

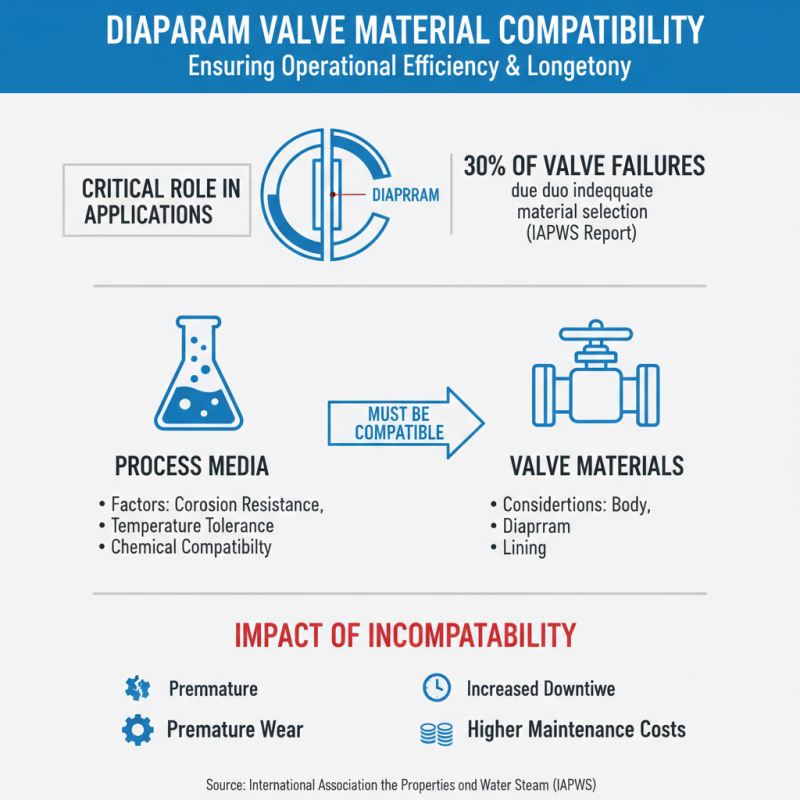

Material Compatibility and Its Importance in Valve Selection

When selecting a diaphragm valve for industrial applications, material compatibility plays a critical role in ensuring operational efficiency and longevity. According to a report by the International Association for the Properties of Water and Steam (IAPWS), approximately 30% of valve failures can be attributed to inadequate material selection, highlighting the need for careful consideration of both the process media and the valve materials. Factors such as corrosion resistance, temperature tolerance, and chemical compatibility are paramount. For instance, a valve made from a material that is incompatible with the process fluid can lead to premature wear or catastrophic failure, increasing maintenance costs and downtime.

Tips for selecting the right materials include conducting thorough compatibility tests using data from organizations like the Corrosion Engineering Association, which provides detailed guidelines on material interactions with various chemicals. It is also advisable to consider environmental factors such as temperature fluctuations and exposure to aggressive substances, which can significantly impact material performance. Utilizing databases that compile material properties and their compatibility with specific fluids can aid in making informed decisions.

Another crucial consideration in diaphragm valve selection is the operational conditions such as pressure and flow rates. A mismatch between the valve material and the operational parameters can lead to stress and eventual failure. Consulting with industry standards outlined by ASTM International can ensure that chosen materials meet the necessary requirements for safety and performance under given conditions.

Evaluating Size and Pressure Requirements for Optimal Performance

When selecting a diaphragm valve for industrial applications, evaluating size and pressure requirements is crucial for ensuring optimal performance. Diaphragm valves are commonly used in systems that involve corrosive fluids or slurries, where maintaining leak-tight integrity is essential. Industry standards indicate that the valve's size should align with the flow requirements of the system. According to a 2021 report by the Fluid Control Institute, improper sizing can lead to inefficient flow, increased energy consumption, and potential system failures.

In addition to size, pressure considerations are paramount. Diaphragm valves typically operate at varying pressure ranges, and selecting a valve rated for higher pressures than your application requires a good practice. This factor not only enhances safety but also ensures longevity in performance. As noted by the International Society of Automation, about 30% of valve failures in industrial settings stem from pressure mishandling.

**Tips:** When assessing pressure requirements, always consult pressure drop charts and consider the system's maximum allowable working pressure. Additionally, factor in ambient conditions, as temperature and fluid characteristics can affect the optimal pressure ratings. Choosing the right size and pressure will deliver reliable and efficient service life across your valve applications.

Maintenance and Longevity Considerations for Diaphragm Valves

Maintaining diaphragm valves is crucial for ensuring their longevity and optimal performance in industrial applications. According to the Valve Manufacturers Association (VMA), proper maintenance practices can extend the lifespan of diaphragm valves by up to 50%. Regular inspections and routine maintenance, including cleaning and lubricating, help prevent wear and detect potential issues early, reducing the risk of unexpected failures. It is recommended that operators establish a maintenance schedule based on the manufacturer’s guidelines and industry standards, which can also include checking for leaks and ensuring that the diaphragm material is compatible with the fluids being handled.

Another vital consideration is the operational environment of the diaphragm valves. The American Society of Mechanical Engineers (ASME) emphasizes that factors such as temperature extremes, pressure fluctuations, and exposure to corrosive substances can significantly affect valve performance and durability. Operators should analyze process conditions to select the right materials, such as elastomers or thermoplastics, that can withstand operational stresses. Additionally, utilizing diaphragm valves with features like blowout prevention and tamper-proof designs may further enhance longevity and reliability in demanding industrial settings.

Related Posts

-

2025's Top 5 Flow Valve Innovations You Need to Know About

-

Best Home Valves for Energy Efficiency in 2023 Based on Industry Data

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Top 5 Home Valve Solutions to Improve Your Plumbing Efficiency

-

Top 10 Valve Home Innovations to Watch in 2025