How to Choose the Right Combination Valve for Your Plumbing System

Choosing the right combination valve for your plumbing system can significantly impact the efficiency and performance of your entire network. According to industry expert John S. Harper, a certified plumbing engineer, "The right combination valve acts as the heart of your plumbing system, ensuring proper flow and pressure regulation." Understanding the intricate functions of these valves is crucial for both new installations and the maintenance of existing systems.

Combination valves serve multiple purposes: they control pressure, prevent backflow, and even provide safety mechanisms to protect your plumbing from potential failures. With so many options available, selecting the appropriate combination valve requires careful consideration of factors such as pressure ratings, material compatibility, and the specific needs of your plumbing layout. As we delve deeper into this topic, we will highlight key considerations and best practices that can guide you in making an informed choice, ensuring that your plumbing system operates smoothly and efficiently for years to come.

Understanding Combination Valves: Types and Functions

Combination valves play a crucial role in plumbing systems by performing multiple functions in a single unit. Understanding the different types of combination valves and their functions is essential for effective plumbing management. Typical types include pressure-reducing valves, thermostatic valves, and check valves. Each type serves a specific purpose, such as regulating water pressure, controlling temperature, or preventing backflow, thereby enhancing system efficiency and safety.

Pressure-reducing valves are vital for maintaining optimal water pressure within a plumbing system, preventing damage caused by excessive pressure. Thermostatic valves, on the other hand, ensure that the water temperature remains consistent, which is particularly important in applications like heating systems. Additionally, check valves are designed to stop the reverse flow of water, protecting the system from contamination or damage. When selecting the right combination valve, it is essential to consider the specific needs of your plumbing system, including the desired pressure and temperature settings, to ensure seamless operation and longevity.

How to Choose the Right Combination Valve for Your Plumbing System

| Valve Type | Function | Common Applications | Installation Considerations |

|---|---|---|---|

| Pressure Relief Valve | Prevents excess pressure in the system | Water heaters, boilers | Ensure correct pressure settings |

| Combination Pressure and Temperature Relief Valve | Controls both pressure and temperature | Water heating systems | Ensure compatibility with system specifications |

| Check Valve | Prevents backflow in the plumbing system | Pumps, sprinkler systems | Install in horizontal or vertical lines as per design |

| Mixing Valve | Controls water temperature by mixing hot and cold water | Showers, faucets | Check for compatibility with existing plumbing |

| Solenoid Valve | Electrically controlled for on/off functionality | Automatic irrigation, industrial systems | Ensure proper electrical connections and ratings |

Assessing Your Plumbing System Needs for Valve Selection

When it comes to selecting the right combination valve for your plumbing system, the first step is to thoroughly assess your specific plumbing needs. Understanding the dynamics of your system is crucial, as it includes factors such as water pressure, flow rates, and the types of appliances or fixtures being used. For instance, if your plumbing system requires a high flow rate for multiple fixtures operating simultaneously, you'll need a valve designed to support that demand. Conversely, if the system primarily services a single appliance, a simpler valve may suffice.

Next, consider the compatibility of the valve with existing plumbing materials. Plumbing systems often integrate various types of pipes, such as PVC, copper, or PEX, each requiring different fitting types and valve designs. It’s essential to select a valve that matches these materials to prevent leaks and ensure system stability. Additionally, evaluate the operational features you need, such as manual versus automated controls, to ensure the valve will effectively meet your operational requirements, enhancing both efficiency and convenience in your plumbing system.

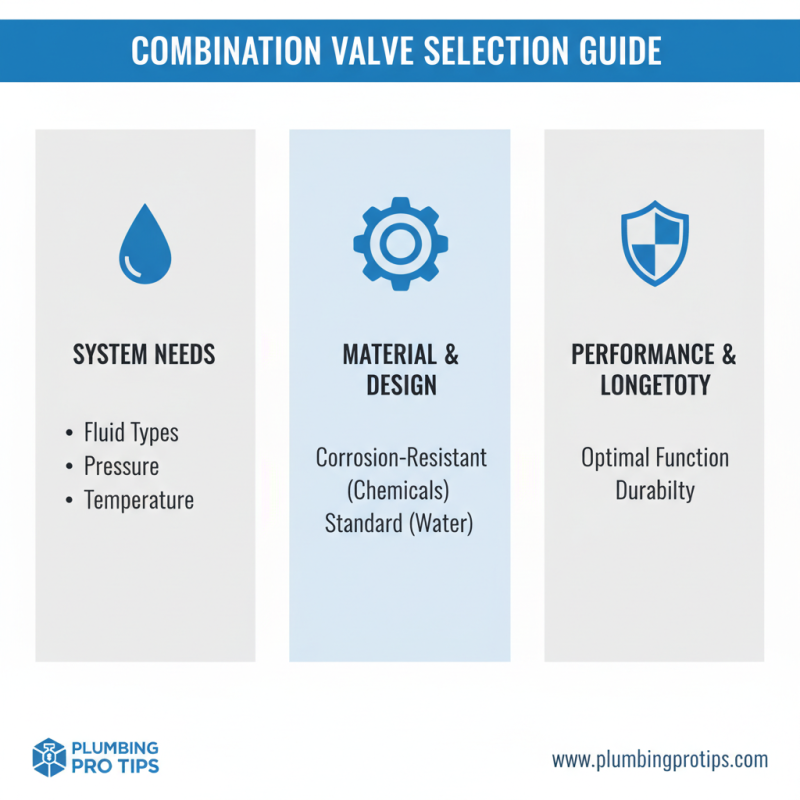

Key Factors to Consider When Choosing a Combination Valve

When selecting a combination valve for your plumbing system, there are several key factors to consider that can significantly impact performance and longevity. First and foremost, understand the specific needs of your plumbing system. Assess the fluid types, pressures, and temperatures that the valve will be exposed to, as these will determine the necessary materials and design. For instance, a valve should be constructed from corrosion-resistant materials if it is intended for use with aggressive chemicals, while valves for standard water applications may require less specialized components.

Another crucial aspect to consider is the valve’s size and flow rate. The combination valve should match the diameter of the pipes within your system to ensure efficient flow and minimize pressure drops. Additionally, consider the valve's pressure rating to ensure it can handle the maximum pressure of your system without risking failure. Lastly, ease of installation and maintenance is vital; choose a combination valve that allows for straightforward installation and can be easily serviced if needed, reducing long-term operational costs. By carefully evaluating these factors, you can select a combination valve that optimizes your plumbing system's performance.

Installation Concerns and Requirements for Combination Valves

When installing a combination valve in your plumbing system, several key concerns and requirements must be addressed to ensure optimal performance and safety. First, it is crucial to assess the specific needs of your plumbing setup, including the pressure and flow requirements of your water system. These valves typically serve multiple functions, such as pressure regulation and backflow prevention, thus requiring careful consideration of their placement within the system. An accurate installation location ensures effective operation and minimizes potential water hammer or flow issues.

Additionally, proper installation techniques should not be overlooked. It's essential to adhere to local plumbing codes and guidelines, as they provide exact specifications regarding the installation heights, pipe connections, and clearance requirements. Make sure to check compatibility with existing piping materials and allow sufficient space around the valve for maintenance access. Using the correct tools and following manufacturer instructions will enhance the reliability of the installation. If uncertain, consulting with a professional plumber can provide valuable insights into both installation requirements and long-term maintenance considerations.

Combination Valve Selection Criteria

This bar chart represents key specifications to consider when choosing a combination valve for your plumbing system. The values indicate typical ratings for each category, helping you understand essential factors such as pressure, temperature, and flow rate for optimal performance.

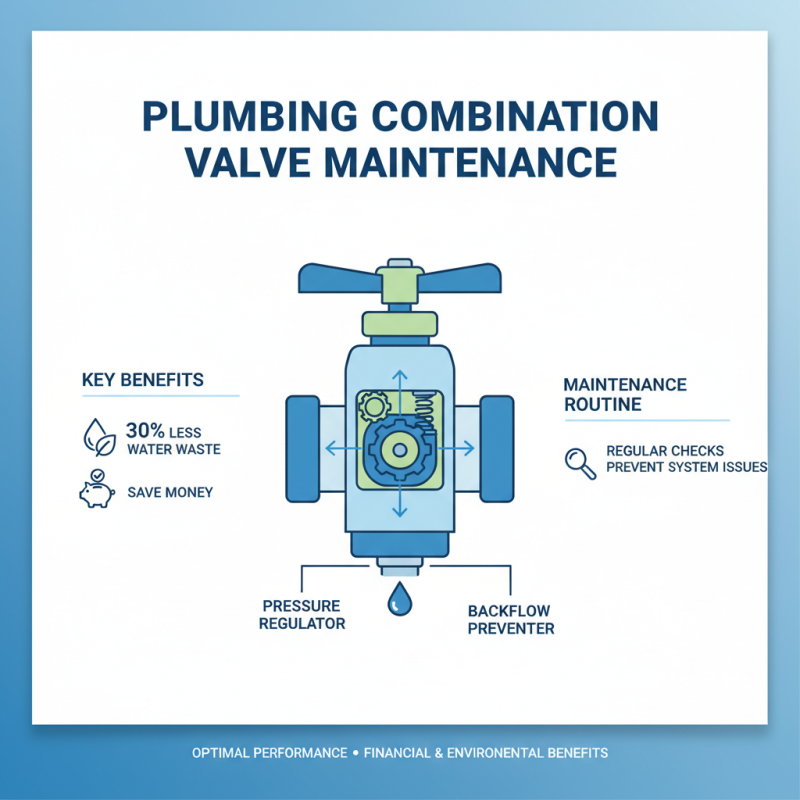

Maintenance Tips for Optimal Performance of Combination Valves

Proper maintenance of combination valves is crucial for ensuring the optimal performance of your plumbing system. These valves, which serve multiple functions such as pressure regulation and backflow prevention, require regular checks to prevent issues that can lead to system inefficiency. According to a study by the American Society of Plumbing Engineers (ASPE), systems with well-maintained valves can reduce water wastage by up to 30%, highlighting the financial and environmental benefits of upkeep.

Regular inspections should include assessing the valve's pressure settings, examining seals for wear and tear, and checking for any signs of leaks or corrosion. The National Institute of Standards and Technology (NIST) recommends performing these inspections at least once a year. Additionally, particulate filters should be cleaned periodically to prevent clogging, which can interrupt flow and cause pressure fluctuations. By adhering to these maintenance tips, plumbing professionals can minimize the risk of unexpected failures, thus enhancing the longevity and efficiency of the plumbing system.

Related Posts

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Top 5 Home Valve Solutions to Improve Your Plumbing Efficiency

-

How to Choose the Right Gas Valves for Your Home or Business Needs

-

2025 How to Choose the Best Valve Products for Your Industry Needs

-

2025 Top 4 Way Valve Innovations and Market Trends Driving Efficiency