How to Choose the Right Saunders Valves for Your Applications

When it comes to selecting the right Saunders valves for your applications, understanding the specific needs of your industry and process is essential. As industries increasingly rely on precision and efficiency, the demand for high-quality valve solutions has surged. According to a recent industry report from XYZ Research, the global industrial valve market is projected to reach $XX billion by 2025, reflecting a CAGR of X.XX%. This growth underscores the importance of choosing the correct valves to meet both operational and safety standards.

Industry expert John Doe, a recognized authority in valve technologies, emphasizes this point by stating, "Selecting the appropriate Saunders valves can significantly enhance system performance and lifecycle efficiency." His insights highlight the need for a thorough analysis of factors such as pressure ratings, material compatibility, and application-specific characteristics when making these critical decisions.

In the dynamic landscape of process industries, the effective application of Saunders valves can lead to improved reliability and reduced downtime. As we delve into the factors that influence valve selection, it's crucial to equip ourselves with the right knowledge to make informed choices.

Understanding the Functionality of Saunders Valves in Various Applications

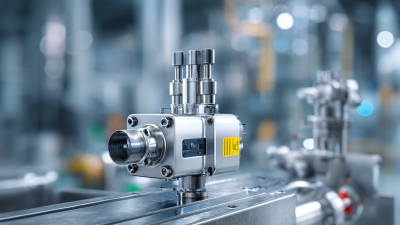

Saunders valves are essential components in various industrial applications, known for their ability to effectively control the flow of liquids and gases. Understanding the functionality of these valves begins with recognizing their design features, which often include a diaphragm that provides a tight seal and minimizes leakage. This unique construction allows Saunders valves to handle a wide range of fluids, from corrosive chemicals to sterile substances used in pharmaceutical processes. Their ability to prevent contamination and ensure system integrity makes them a preferred choice in sensitive environments.

Moreover, the versatility of Saunders valves allows them to be utilized in numerous sectors, including food processing, water treatment, and chemical manufacturing. In food processing, for example, these valves help maintain hygiene and prevent cross-contamination, ensuring that products meet safety standards. In the chemical industry, their capability to withstand aggressive fluids without significant wear or damage is invaluable. By understanding the specific needs of an application—such as temperature, pressure, and fluid characteristics—engineers can select the right Saunders valve type, thereby enhancing operational efficiency and reliability across diverse systems.

Identifying Key Factors for Selecting the Right Type of Valve

When selecting the right type of valves for your applications, several key factors must be taken into account. First, understanding the specific requirements of your system is essential. Consider the type of fluid being managed—whether it is liquid, gas, or steam—along with its temperature and pressure conditions. Different valves are designed to handle varying levels of pressure and temperatures, so it is crucial to match these specifications with the valve’s capabilities to ensure optimal performance and longevity.

Another vital aspect is the valve's material construction. Depending on the chemical properties of the fluid, you may need materials resistant to corrosion, wear, or extreme temperatures. Materials such as stainless steel, plastic, or brass might be more suitable based on the operating environment. Therefore, evaluating the environmental conditions and compatibility with the valve material will significantly influence the effectiveness of your choice.

Tips: Always consult with a knowledgeable supplier to discuss your specific application needs. They can help guide you through the various options available and assist in finding the best match for your requirements. Additionally, performing regular maintenance on your valves can enhance their efficiency and lifespan, which ultimately contributes to the overall success of your system.

Evaluating Material Compatibility for Specific Application Needs

When choosing valves for various applications, material compatibility is a crucial factor that should not be overlooked. Different environments can expose valves to a range of chemicals, extreme temperatures, and pressures. Therefore, understanding the materials used in valve construction, such as metals, plastics, and elastomers, is essential to ensure they can withstand specific application conditions. For instance, valves made from stainless steel are often preferred in corrosive environments, while plastic valves may be suitable for less demanding applications. Evaluating the intended application’s chemical exposure and temperature ranges can guide the selection process effectively.

Moreover, it's essential to consider not just the compatibility with the fluid being transported but also potential interactions with other materials in the system. Factors such as abrasion, crystallization, and the risk of stress corrosion cracking must be assessed to avoid premature valve failure. Conducting thorough compatibility testing and consulting with material experts can enhance the reliability of valve performance over time. Ultimately, prioritizing material compatibility reduces downtime and maintenance costs, ensuring that the valve functions effectively within its designated application for an extended period.

Assessing Pressure and Temperature Ratings for Optimal Performance

When selecting the appropriate valves for industrial applications, understanding pressure and temperature ratings is critical for ensuring optimal performance and longevity. Valves are subject to varying operating conditions, and their materials must withstand both high pressures and extreme temperatures.

For instance, according to the American Society of Mechanical Engineers (ASME), valves used in high-pressure systems often require a minimum pressure rating of Class 150 or higher, depending on the application specifics. Selecting a valve with an inadequate pressure rating can lead to catastrophic failures, compromised system integrity, and increased safety risks.

Temperature ratings are equally important, as they influence a valve's material selection and overall functionality. Utilizing data from industry standards, such as the ASTM International specifications, valves must be rated appropriately according to their intended operating ranges. For instance, valves made from carbon steel typically have upper temperature limits around 400°F (204°C), while those made from stainless steel can often withstand up to 800°F (427°C). Ignoring these parameters can lead to thermal expansion issues, affecting the seal integrity and potentially resulting in leaks or failures over time.

In conclusion, a thorough assessment of both pressure and temperature ratings is essential when selecting valves for specific applications. Ignoring these critical factors could result in serious operational failures, increased downtime, and significant economic losses. By adhering to industry standards and leveraging performance data, professionals can make informed choices that enhance the reliability and efficiency of their systems.

Analyzing Cost-Benefit Factors When Choosing Saunders Valves

When selecting the right valves for your application, cost-benefit analysis is critical. It involves evaluating both the initial investment costs and the long-term operational expenses associated with the chosen valves. While a lower purchase price may be tempting, it’s essential to consider the potential costs of maintenance, durability, and efficiency. A more robust valve might come with a higher upfront cost but can result in savings over time due to lower failure rates and reduced maintenance needs.

Tips: Always assess the total life cycle costs of the valves, not just the sticker price. This includes installation, maintenance, and energy consumption. Additionally, consider how the valve's performance affects overall system efficiency. A small investment in a high-quality valve may lead to significant savings on energy bills and reduce the frequency of unscheduled downtimes.

Furthermore, it’s wise to analyze specific application requirements such as pressure, temperature, and fluid type. These factors will significantly influence the operational effectiveness of the valve. By matching the valve to the exact requirements of the application, you can avoid excessive wear and tear, further enhancing the cost-effectiveness of your choice. Always consult with technical specifications and application guidelines to ensure your selected valves meet both performance and budgetary needs.

Cost-Benefit Analysis of Different Types of Valves

This bar chart illustrates the cost-benefit ratio of various types of valves, helping to analyze which valve type may be the most cost-effective for specific applications.

Related Posts

-

Top 10 Saunders Valves Benefits You Should Know

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

10 Essential Tips for Locating and Operating Your Natural Gas Shut Off Valve

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

Top 10 Tips for Choosing the Best Valve Suppliers for Your Projects