Top Tips for Choosing and Maintaining Your Recirculation Valve

Choosing and maintaining a recirculation valve is crucial for ensuring the efficiency and longevity of various systems, particularly in HVAC and water heating applications. The recirculation valve serves a vital role in controlling the flow of fluid, allowing for optimal temperature regulation and energy savings. With proper selection and maintenance, a recirculation valve can significantly improve system performance and reduce operational costs.

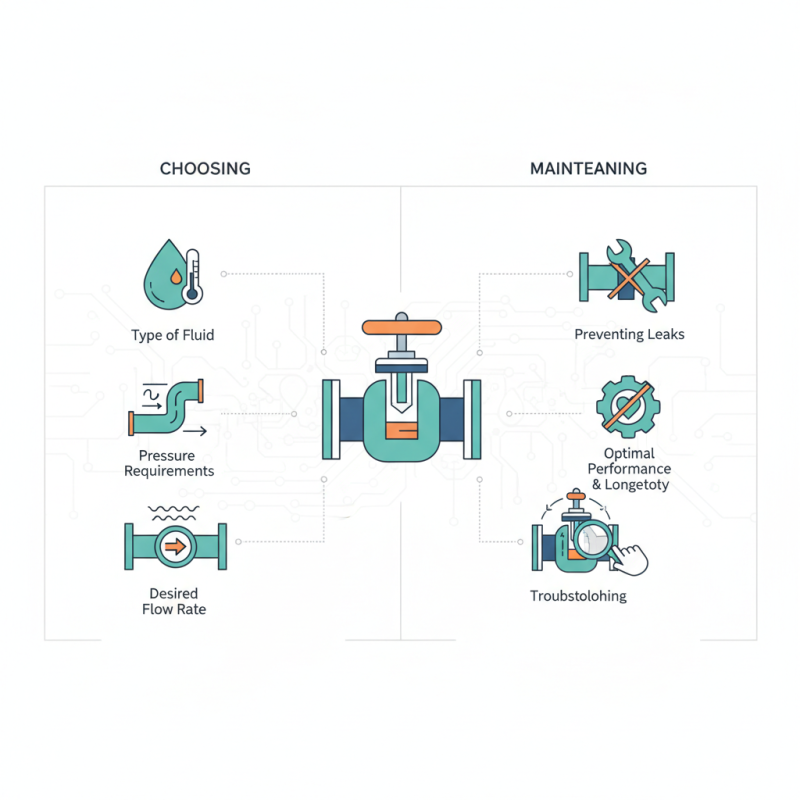

When it comes to selecting the right recirculation valve, there are several key factors to consider, such as the type of fluid, pressure requirements, and the desired flow rate. Each of these elements plays a critical part in determining the most suitable valve for your specific application. Additionally, regular maintenance is essential to prevent common issues such as leaks or blockages that can hinder performance. Understanding how to care for and troubleshoot your recirculation valve can ensure that it functions efficiently throughout its lifespan.

In this article, we will explore essential tips for choosing the right recirculation valve and best practices for maintaining it. Whether you're a homeowner looking to improve your plumbing system or an HVAC professional aiming to optimize installations, these insights will help you make informed decisions and keep your systems running smoothly.

Understanding Recirculation Valves and Their Functionality

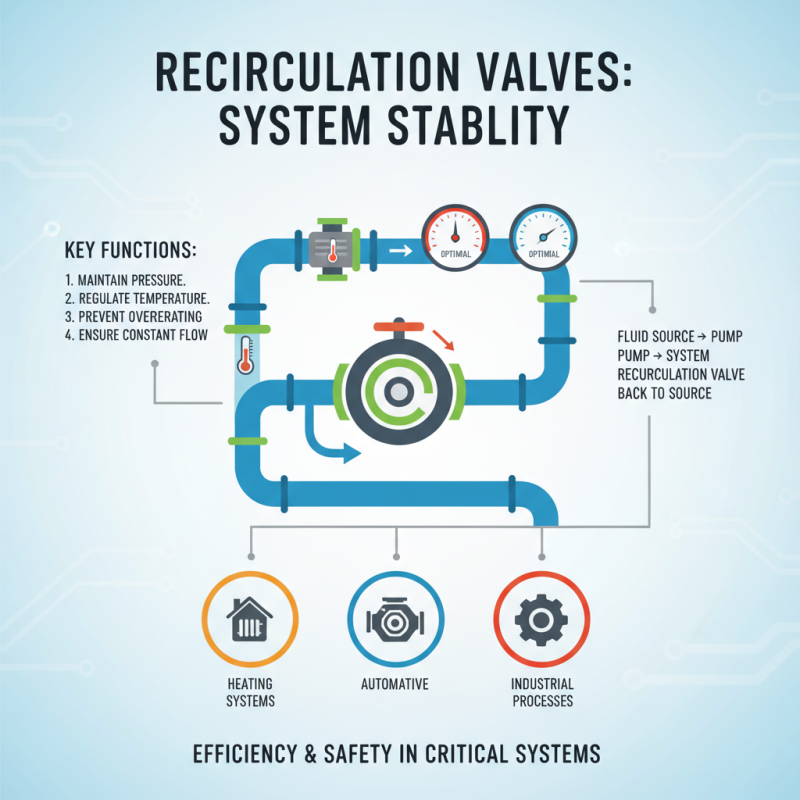

Recirculation valves are essential components in various systems, primarily functioning to maintain optimal pressure and temperature. By rerouting fluids back to a source, these valves help to maintain stable conditions within the system, preventing issues like overheating or pressure drops. They play a crucial role in applications such as heating systems, automotive engines, and industrial processes, where constant flow is necessary for efficiency and safety.

Understanding the functionality of recirculation valves is vital for anyone looking to implement or maintain such systems. The design typically includes features like a variable or fixed orifice, which allows for control over the flow rate. Additionally, these valves can be actuated either manually or automatically, depending on the system's needs. Regular maintenance, including cleaning and inspecting seals and actuators, ensures these valves operate effectively, minimizing the risk of failure and prolonging the life of associated equipment. A thorough comprehension of these components not only aids in proper selection but also in choosing the right maintenance routines to keep them functioning optimally.

Key Factors to Consider When Choosing a Recirculation Valve

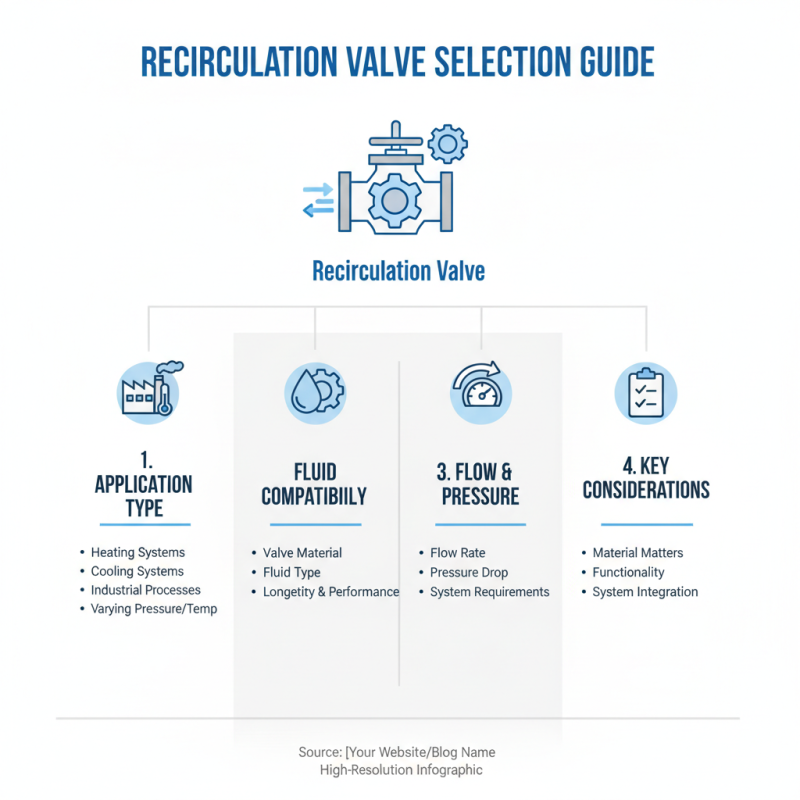

When selecting a recirculation valve, the first key factor to consider is the application it will serve. Different systems, such as heating, cooling, and industrial processes, may require specific types of valves that can handle varying pressures and temperatures. Ensure that the valve material is compatible with the fluids it will manage, as this plays a crucial role in longevity and performance. Additionally, assessing the flow rate and pressure drop across the valve can help determine if it meets your system’s requirements effectively.

Another important aspect is the maintenance of the recirculation valve. Regular inspection for wear and tear is vital to prevent unexpected failures. Look for valves equipped with features that simplify maintenance, such as easily accessible stems or removable components. Moreover, consider the ease of installation, as a straightforward installation process can significantly reduce downtime during maintenance operations. Always refer to the manufacturer’s guidelines and recommendations to ensure optimal performance and reliability of the valve throughout its lifespan.

Best Practices for Installing a Recirculation Valve Properly

When it comes to installing a recirculation valve, attention to detail is essential. According to a report by the American Society of Plumbing Engineers, improper installation can lead to inefficiencies that may increase energy costs by up to 20%. To achieve optimal performance, it is vital to follow best practices that begin with selecting the right location. The valve should be installed close to the hot water source, such as a water heater, to minimize waiting time for hot water and enhance overall system efficiency.

Furthermore, ensuring that the plumbing connections are secure and leak-free is crucial. A study published by the International Association of Plumbing and Mechanical Officials indicates that 30% of plumbing issues stem from poor installation practices. Proper torque specifications should be adhered to, and the use of thread sealant suitable for your system type can help prevent leaks. Additionally, consider employing a professional with experience in system installations to avoid common pitfalls and ensure compliance with local codes and regulations. Following these best practices will not only extend the lifespan of your recirculation valve but also improve energy efficiency in your plumbing system.

Top Tips for Choosing and Maintaining Your Recirculation Valve

This chart displays the frequency of key best practices for installing and maintaining recirculation valves based on a survey of industry professionals.

Routine Maintenance Tips to Ensure Optimal Valve Performance

Routine maintenance is essential for ensuring the optimal performance of your recirculation valve. Regularly check for leaks or signs of wear around the valve body. Addressing these issues early can prevent costly repairs and ensure that your valve operates efficiently.

Another crucial tip is to clean the valve and its surrounding area regularly. Dust and debris can build up and interfere with the valve's operation. Use a soft cloth and appropriate cleaning solution to keep the valve clear and functioning smoothly. Additionally, consider inspecting the elastomer seals for any signs of deterioration. Replacing worn seals promptly can help maintain a proper seal, thereby enhancing the overall efficiency of the system.

Lastly, don’t forget to monitor the pressure and flow rates associated with the valve. Keeping track of these metrics can help you identify any irregularities that may indicate a larger issue. Regularly testing these parameters ensures that your recirculation valve performs at its best, prolonging its lifespan and maintaining system integrity.

Top Tips for Choosing and Maintaining Your Recirculation Valve - Routine Maintenance Tips to Ensure Optimal Valve Performance

| Aspect | Recommendation | Frequency | Notes |

|---|---|---|---|

| Choosing the Right Size | Consult with a professional to determine the appropriate size for your system. | Once, during installation | Improper size can lead to inefficiencies. |

| Regular Inspection | Inspect the valve for leaks and wear. | Monthly | Early detection can prevent costly replacements. |

| Cleaning | Clean valve surfaces and surrounding area. | Quarterly | Keep free of debris for optimal performance. |

| Lubrication | Apply lubrication as advised by the manufacturer. | Biannually | Prevents seizing and maintains functioning. |

| System Testing | Perform pressure and flow tests. | Annually | Ensures the valve is operating within specifications. |

Common Issues and Troubleshooting for Recirculation Valves

When it comes to recirculation valves, being aware of common issues can significantly enhance their functionality and longevity. One prevalent problem is improper sealing, which can lead to leaks and reduced system efficiency. Regular inspection of the valve's seals and gaskets is essential to ensure they are in good condition. If any wear is detected, timely replacement can prevent further complications that might arise from continuous leaks, such as pressure drops or system contamination.

Another frequent issue is the buildup of sediment or debris within the valve. This can impede the flow and affect the overall performance of the system. To address this, routine maintenance, including cleaning the valve and flushing the system, is advisable. Additionally, if the valve is failing to open or close properly, it may indicate mechanical failure or inadequate power supply, necessitating a thorough examination of the actuators. Identifying these signs early can prevent costly repairs and ensure that the recirculation system operates smoothly and efficiently.

Related Posts

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Top 5 Home Valve Solutions to Improve Your Plumbing Efficiency

-

Best Home Valves for Energy Efficiency in 2023 Based on Industry Data

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

Top 10 Valve Home Innovations to Watch in 2025