2025 How to Choose the Best Valve Products for Your Industry Needs

Choosing the right valve products is crucial for optimizing operations across various industries. With an ever-expanding range of valves available, the decision-making process can often feel overwhelming. Understanding the specific requirements of your industry—whether it be oil and gas, water treatment, food processing, or manufacturing—is essential for selecting the most appropriate valve solutions. This guide will delve into the key factors you should consider when evaluating valve products to meet your operational needs effectively.

As industries evolve and regulatory standards become more stringent, the importance of selecting quality valve products cannot be overstated. A well-chosen valve can enhance efficiency, ensure safety, and minimize maintenance costs. In this article, we will highlight critical considerations such as fluid compatibility, pressure requirements, and environmental factors, empowering you to make informed decisions. By examining these guidelines, you can navigate the complexities of the valve market and select products that not only meet your immediate needs but also support long-term operational goals.

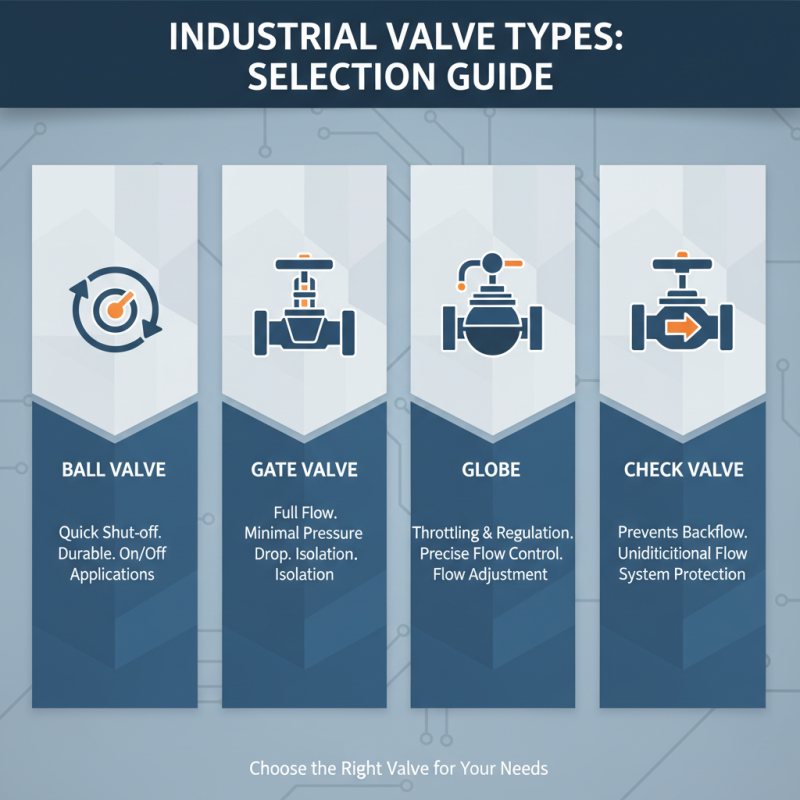

Understanding Different Types of Valves for Industry Applications

When selecting valve products for specific industry applications, it is essential to understand the various types of valves available and their distinct functions. Common types include ball valves, gate valves, globe valves, and check valves, each designed for specific operational needs. For instance, ball valves are favored for their quick shut-off capability and durability, making them suitable for on/off applications. On the other hand, globe valves are ideal for throttling and regulating flow, providing more precise control in processes where flow adjustments are vital.

In addition to recognizing valve types, it’s crucial to consider the materials used in their construction. Valves can be made from metals like stainless steel or brass, or from plastic compounds, impacting their compatibility with different fluids and gases. Factors such as temperature, pressure, and the fluid’s chemical properties are essential when choosing the right material. Moreover, understanding the application environment—whether it is high-pressure, high-temperature, or corrosive—can significantly influence the longevity and performance of the valve. By carefully evaluating these aspects, industries can ensure they select the best valve products tailored to their operational requirements.

Evaluating Valve Materials for Durability and Compatibility

When selecting valve products for specific industry applications, evaluating the materials used in their construction is crucial for ensuring both durability and compatibility with the intended service environment. Valves must be designed to withstand various operational stresses, including pressure, temperature, and chemical exposure. Common materials such as stainless steel, carbon steel, and plastic each offer distinct advantages and limitations. Stainless steel, for instance, is favored for its superior corrosion resistance and strength, making it ideal for demanding applications in chemical processing or oil and gas industries. Conversely, plastic valves can provide lightweight solutions for less demanding environments while still offering good chemical resistance.

Compatibility between the valve material and the operational fluids is also essential to prevent premature failure and ensure safety. For instance, certain rubber and plastic materials may degrade when exposed to aggressive chemicals, while metals may be susceptible to corrosion in certain environments. Conducting thorough compatibility testing is essential, alongside considering factors such as temperature variations and potential stressors that could lead to material fatigue over time. By paying close attention to these material characteristics, businesses can select valve products that not only meet their current needs but also provide reliable, long-term performance across various conditions.

2025 How to Choose the Best Valve Products for Your Industry Needs - Evaluating Valve Materials for Durability and Compatibility

| Valve Type | Material | Temperature Range (°C) | Pressure Rating (PSI) | Applications |

|---|---|---|---|---|

| Ball Valve | Stainless Steel | -30 to 200 | 150 | Water, Oil, Gas |

| Gate Valve | Cast Iron | -10 to 180 | 300 | Water Supply, Drainage |

| Globe Valve | Bronze | 0 to 150 | 200 | Steam, Oil |

| Check Valve | PVC | 5 to 60 | 160 | Chemical Transport |

| Butterfly Valve | Aluminium | -20 to 150 | 250 | HVAC, Water Distribution |

Assessing Valve Performance Metrics and Operational Requirements

When selecting valve products for specific industry needs, it is crucial to assess performance metrics and operational requirements thoroughly. According to a recent report by the Flow Control Association, approximately 60% of valve failures in industrial applications stem from issues related to inadequate performance specifications. This emphasizes the need for a detailed understanding of various performance indicators, such as flow coefficient (Cv), pressure drop, and temperature range. For instance, a valve's flow coefficient directly affects its efficiency in controlling the fluid flow, making it essential to match this metric with the operational conditions of the system.

Moreover, operational requirements, including material compatibility and environmental factors, play a significant role in valve selection. A survey conducted by the American Society of Mechanical Engineers found that 70% of maintenance professionals cite material degradation as a top concern, particularly in corrosive environments. Therefore, choosing materials that withstand specific temperature and pressure conditions while ensuring resistance to corrosion and wear is vital. By focusing on both performance metrics and the specific demands of operational environments, industries can enhance reliability and longevity in their valve systems, ultimately leading to reduced downtime and maintenance costs.

Identifying Industry-Specific Standards and Regulations for Valves

When selecting valve products for specific industry needs, it is crucial to understand the relevant standards and regulations that apply. Different industries, such as oil and gas, pharmaceuticals, and water management, have their unique compliance criteria that ensure safety, efficiency, and environmental protection. Familiarizing yourself with these standards can significantly influence your decision-making process and the selection of appropriate valve types.

**Tips:** Always start by identifying the key regulations governing your industry. For instance, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide vital guidelines for valve specifications in many sectors. Additionally, consider the requirements set forth by industry-specific organizations, as these can provide insights into safety standards and performance expectations.

It is also essential to evaluate how these regulations impact valve materials and designs. For example, valves used in corrosive environments may need to meet specific material standards to prevent failure or leaks. Always consult with regulatory bodies or industry experts to ensure that your chosen valves not only meet but exceed the required standards, allowing for reliable and compliant operations.

**Tips:** Engage with industry forums or workshops to stay updated on best practices and emerging regulations. Networking with peers can provide valuable insights and aid in making informed decisions when selecting valve products tailored to your industry's specific needs.

2025 Valve Product Selection by Industry Standards

Selecting the Right Valve Supplier and Support Services

Choosing the right valve supplier is crucial for ensuring that your industrial applications run smoothly and efficiently. When evaluating potential suppliers, it's important to consider their experience and expertise in your specific industry. A supplier with a proven track record of providing high-quality valve solutions tailored to your needs can make a significant difference in operational performance. Look for suppliers who not only understand the technical specifications required for your application but also offer innovative solutions that can enhance your processes.

In addition to product knowledge, support services play a vital role in selecting a valve supplier. Effective after-sales support ensures that you have access to technical assistance when needed, as well as routine maintenance and emergency repairs. Evaluate the supplier's commitment to customer service by researching their response times and availability of support staff. A supplier that offers comprehensive training for your team can also be invaluable, as it empowers your personnel to operate and maintain valve systems efficiently, minimizing downtime and maximizing productivity. By carefully assessing both the product offerings and the quality of support services, you can choose a valve supplier that aligns perfectly with your industry's needs.

Related Posts

-

Top 10 Valve Home Innovations to Watch in 2025

-

How to Choose the Right Diaphragm Valve for Your Industrial Application

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

Unlocking Efficiency: How Lever Valves Can Reduce Energy Consumption by Up to 30% in Industrial Applications

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

2025 Top 4 Way Valve Innovations and Market Trends Driving Efficiency