How to Choose the Right Flow Check Valve for Your Application Needs

In today's industrial landscape, selecting the appropriate flow check valve is critical to ensuring the efficiency and safety of fluid systems. According to John Stevens, a renowned expert in fluid dynamics, “The right flow check valve can significantly reduce operational costs and enhance system reliability.” With numerous designs and specifications available, the decision-making process can often seem overwhelming. However, understanding your specific application needs can streamline this selection.

Flow check valves play a pivotal role in preventing backflow, protecting pumps, and ensuring consistent flow in various applications—from water treatment to chemical processing. Choosing the right valve involves evaluating factors such as the type of fluid, pressure conditions, and the required flow rate. As industries continue to evolve, the demand for reliable and efficient flow control solutions grows, underlining the importance of making informed decisions when selecting a flow check valve tailored to your unique requirements.

Understanding Flow Check Valves: Types and Applications

Flow check valves are essential components in various fluid systems, playing a crucial role in regulating the direction of flow and preventing backflow.

There are several types of flow check valves—such as swing check, lift check, and ball check valves—each designed to meet specific operational requirements.

Swing check valves utilize a hinged disc that swings open for forward flow and closes to prevent reverse flow, making them ideal for low-pressure applications.

Lift check valves, on the other hand, feature a movable disc that lifts off its seat when fluid flows through, providing a tighter seal and minimizing leakage, which is beneficial in high-pressure environments.

When selecting a flow check valve for a particular application, factors such as fluid type, pressure levels, and temperature must be considered.

For instance, in systems handling viscous fluids, ball check valves can be advantageous due to their ability to manage thicker materials without obstruction.

Additionally, the installation orientation of the valve significantly influences its functionality; some valves are designed to operate effectively in vertical positions, while others are better suited for horizontal installations.

Understanding these various types and their specific applications helps engineers and system designers make informed choices that enhance the performance and reliability of their fluid systems.

Key Factors to Consider When Selecting a Flow Check Valve

When selecting a flow check valve, it's crucial to consider several key factors that directly impact the efficiency and safety of the application. One of the primary factors is the type of fluid being handled. According to a report by the Flow Control Magazine, approximately 70% of industrial applications involve various types of liquids—ranging from water to corrosive substances. Understanding the fluid's viscosity, temperature, and chemical properties can guide engineers in choosing a valve material that can withstand these conditions. For instance, high-performance polymer valves are often recommended for corrosive environments, where metals may falter.

Another significant aspect is the pressure and flow rate requirements. The American Society of Mechanical Engineers (ASME) emphasizes that selecting a valve with the appropriate pressure rating is critical in avoiding system failures. Data shows that nearly 30% of valve failures in pipelines are attributed to mismatched pressure ratings. Additionally, ensuring that the valve can handle the expected flow rate without causing turbulence or cavitation is vital. Engineers should refer to the valve’s flow coefficient (Cv) value, which indicates its capacity to allow flow; this quantification aids in determining if the valve will operate effectively in the desired scenario.

Lastly, installation and maintenance considerations should not be overlooked. Many industry reports highlight the importance of ease of installation—choosing a valve compatible with existing piping systems can reduce downtime and labor costs. Similarly, a valve that requires minimal maintenance will enhance reliability and longevity, contributing to substantial cost savings over time. By addressing these factors—fluid characteristics, pressure/flow requirements, and maintenance ease—one can make an informed decision when selecting the right flow check valve for specific application needs.

Comparison of Flow Check Valve Types

Industry Standards and Certifications for Flow Check Valves

When selecting a flow check valve for specific application needs, understanding the relevant industry standards and certifications is crucial. Flow check valves play a pivotal role in ensuring fluid systems operate efficiently and safely. According to the International Standard Organization (ISO), certain standards such as ISO 9001 emphasize quality management systems that ensure product consistency, reliability, and safety. Incorporating these standards in the selection process guarantees that the valves will adhere to the required operational parameters in a given application.

Additionally, national and international certifications like the American Society of Mechanical Engineers (ASME) codes and the American National Standards Institute (ANSI) guidelines offer critical benchmarks for performance and safety. Reports from industry analysts indicate that approximately 75% of industries rely on such standards to mitigate risks associated with fluid control systems. By choosing flow check valves that comply with these standards, organizations can significantly reduce the likelihood of failure and enhance the longevity of their systems, ultimately leading to lower maintenance costs and higher operational efficiency.

How to Choose the Right Flow Check Valve for Your Application Needs - Industry Standards and Certifications for Flow Check Valves

| Dimension | Standard/Certification | Material | Pressure Rating | Temperature Range |

|---|---|---|---|---|

| 1/2" - 2" | API 600 | Carbon Steel | 150 PSI | -20°F to 250°F |

| 2" - 4" | ASME B16.34 | Stainless Steel | 300 PSI | -40°F to 300°F |

| 4" - 6" | ISO 16069 | Bronze | 150 PSI | -20°F to 200°F |

| 6" - 10" | ANSI/API Spec 6A | PVC | 100 PSI | 32°F to 140°F |

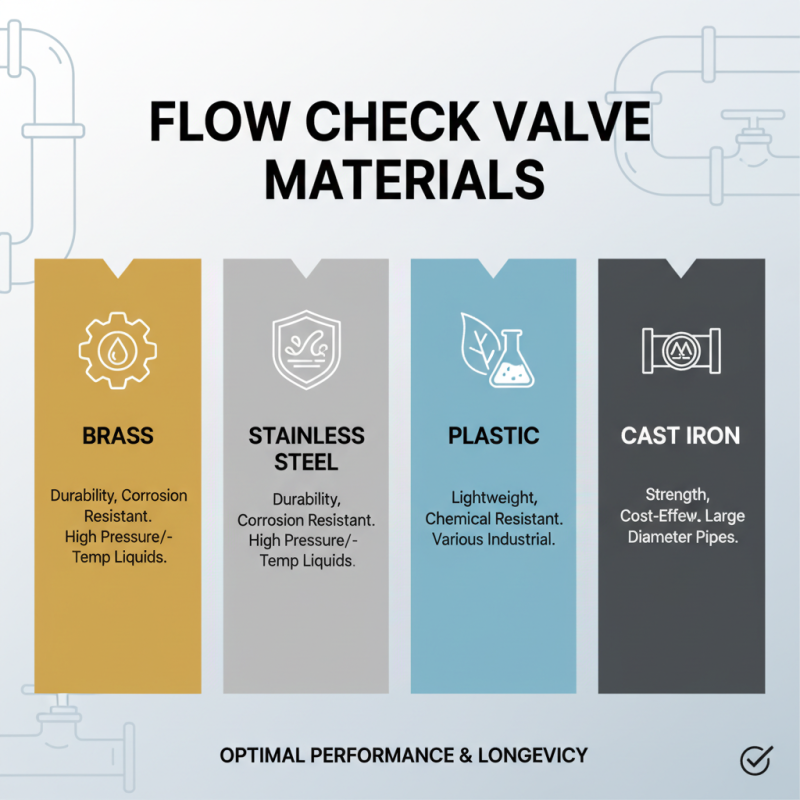

Common Materials Used in Flow Check Valve Construction

When selecting a flow check valve, understanding the materials used in its construction is crucial for ensuring optimal performance and longevity. Common materials include brass, stainless steel, plastic, and cast iron, each offering distinct advantages based on the specific application and environment. For instance, brass and stainless steel are preferred for their durability and resistance to corrosion, making them ideal for applications involving liquids with high pressure or temperature variations. On the other hand, plastic valves are lightweight and resistant to various chemicals, which may be necessary in certain industrial settings.

Tips: When choosing a material, consider the fluid type, temperature, and pressure requirements of your application. Always review compatibility charts for materials to avoid costly failures or leaks in your system.

In addition to material types, the construction quality of the valve itself can greatly affect its functionality. For example, valves with a full-port design allow for maximum flow and minimal turbulence, whereas reduced-port designs can offer cost savings in lighter applications. It's essential to match the valve's construction with your system's demands to enhance efficiency and reliability.

Tips: Before finalizing your selection, conduct a thorough assessment of your application’s pressures and fluid characteristics. A little research into the application context can prevent future operational issues and extend the life of your flow check valve.

Maintenance and Performance Metrics for Flow Check Valves

When selecting a flow check valve for your application, understanding maintenance and performance metrics is essential to ensure optimal functionality. Regular maintenance is crucial to prevent malfunction and extend the lifespan of the valve. This involves routine inspection for any signs of wear or damage, such as corrosion or debris accumulation that may impede flow. Proper cleaning and lubrication of the valve parts are also necessary to maintain smooth operation and reduce friction, which can lead to performance degradation over time.

Performance metrics are key indicators of how effectively a flow check valve performs in its intended application. Factors such as pressure drop, flow rate, and response time should be monitored regularly to ensure the valve operates within the optimal range. Deviations from these metrics could signal underlying issues that require immediate attention. Additionally, understanding the media characteristics—such as temperature, viscosity, and chemical composition—can greatly influence the valve's performance. By closely tracking these parameters, users can make informed decisions regarding maintenance schedules and potential upgrades to enhance system efficiency.

Related Posts

-

2025's Top 5 Flow Valve Innovations You Need to Know About

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

10 Essential Tips for Locating and Operating Your Natural Gas Shut Off Valve

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

How to Choose the Right Diaphragm Valve for Your Industrial Application

-

Top 5 Home Valve Solutions to Improve Your Plumbing Efficiency