How to Choose the Best Ball Valve Manufacturers for Your Needs?

Choosing the right ball valve manufacturers is crucial for various industries. Ball valves are essential components for controlling fluid flow. According to a recent report by MarketsandMarkets, the global ball valve market is expected to grow from $4.2 billion in 2021 to $6.3 billion by 2026. This growth indicates a rising demand for high-quality valves in oil and gas, water treatment, and power generation sectors.

With numerous manufacturers available, selecting the best can be challenging. Quality, reliability, and performance must be prioritized. Not all ball valve manufacturers adhere to industry standards. Some may cut corners to reduce costs, resulting in subpar products. Attention to detail is vital when assessing manufacturer credentials and customer feedback.

Geographical factors also play a significant role in this decision. Proximity to suppliers can affect lead times and logistical costs. Evaluating potential suppliers requires thorough research and practical considerations. Recognizing these factors can lead to better decision-making in choosing ball valve manufacturers that meet industry demands.

Understanding Ball Valves and Their Applications

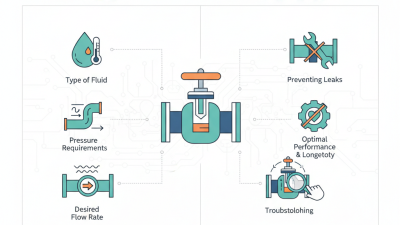

Ball valves are crucial components in various industries. They control the flow of liquids and gases effectively. Available in different sizes and materials, these valves offer versatility and reliability. Understanding their applications helps in selecting the right type for specific needs.

When choosing a ball valve, consider the medium it will handle. For example, some valves are ideal for water, while others excel with chemicals. Temperature and pressure ratings also play a significant role. Using a valve beyond its specifications can lead to failures. Pay attention to the environment in which the valve will operate.

**Tips:** Always verify specifications. A valve that works well in one situation may fail in another. Check for maintenance needs. Some valves require more care than others. Lastly, don't hesitate to seek expert advice. Reflect on your actual needs, and compare options thoroughly.

How to Choose the Best Ball Valve Manufacturers for Your Needs?

| Feature | Importance Level | Considerations |

|---|---|---|

| Material Quality | High | Ensure durability and corrosion resistance. |

| Size Range | Medium | Check compatibility with your piping system. |

| Pressure Rating | High | Ensure it can handle your operational pressure. |

| Leak Rate | High | Consider manufacturing standards for sealing. |

| Certification | Medium | Look for industry certifications like ISO. |

| Warranty | Medium | Check the warranty terms offered. |

| Customer Support | Medium | Assess the responsiveness and availability. |

| Price | Medium | Balance between cost and quality. |

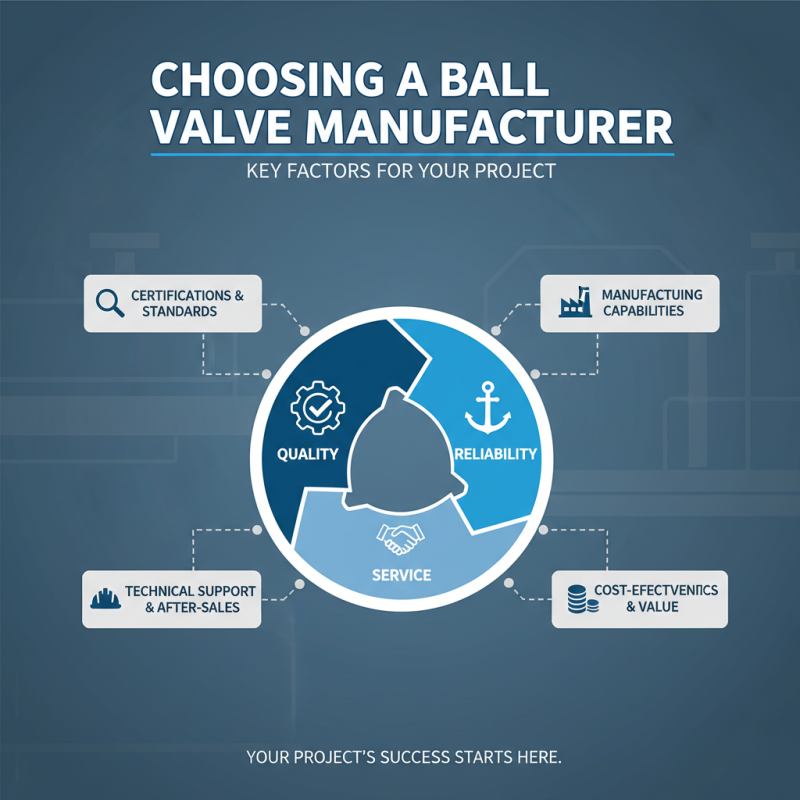

Key Factors to Consider When Choosing a Ball Valve Manufacturer

Choosing the right ball valve manufacturer is crucial for your project. Quality, reliability, and service are key factors to think about. Here are some essential aspects to consider.

Evaluate the manufacturer’s experience in the industry. A company with a history of producing high-quality products will likely offer better options. Look for certifications and standards they meet. This can hint at their manufacturing processes and quality control.

Tips: Always check customer reviews. They provide insights about the manufacturer’s reliability. Ask for samples if possible. Testing products can help you assess their quality before making a large order.

The range of materials they offer is another factor. Different applications require different materials. Make sure the manufacturer provides options suitable for your specific needs. Don’t overlook after-sales support. A manufacturer that offers reliable support can save you time and money in the long run.

Tips: Consider the manufacturer’s location. Local suppliers may offer faster shipping and support. Communication ease is also an important aspect. Effective communication can lead to improved project outcomes.

Evaluating Manufacturer Reputation and Product Quality

When evaluating ball valve manufacturers, reputation is key. Industry studies show that 75% of customers prioritize quality over price. A manufacturer’s track record can reveal much about their reliability. Look for those with a long-standing presence in the market. Newer companies might offer lower prices, but their quality cannot be assured.

Certification is another important factor. Manufacturers often seek ISO certifications to validate their processes. A report from the Valve Manufacturers Association noted that certified products had a 30% lower failure rate in critical applications. However, some companies may exploit this system. Researching their certification claims is crucial.

Product quality speaks volumes. Many manufacturers may promise durability but fail in real-world conditions. Some industry tests show that up to 40% of valve failures occur due to subpar materials. Inconsistencies in manufacturing processes can contribute to this issue. Ask for test results and performance data. Aim for transparency, but remember, a perfect provider may not exist. It’s about finding reliability amid imperfections.

Assessing Customer Support and Technical Assistance Offerings

When selecting a ball valve manufacturer, customer support is vital. A responsive support team can resolve issues quickly. Consider how accessible they are. Do they offer a hotline? Is there an email support option? These aspects can make a big difference in your experience.

Additionally, technical assistance offerings are essential. Manufacturers that provide comprehensive installation guides are very helpful. Look for those with online resources. Video tutorials can simplify complex processes. Engaging live chat options show commitment to customer care. Keep in mind, some manufacturers may not excel in these areas.

Not every company offers robust post-purchase support. You might encounter delays or vague responses. It’s good to question what happens after the sale. Reflection on these aspects can reveal much about a manufacturer’s reliability. The right support can lead to smoother operations. Make an informed choice.

Comparing Pricing and Warranty Options Among Manufacturers

When evaluating ball valve manufacturers, pricing and warranty options are crucial. Different manufacturers offer varying price points. Some may seem cheaper at first glance. However, lower prices can indicate compromised quality. It's essential to balance cost with the reliability of the product. A higher price may reflect superior materials and craftsmanship. Always ask for a detailed quote.

Warranties can provide peace of mind. Many manufacturers offer a limited warranty lasting one to five years. This shows their confidence in their products. A solid warranty can hint at durability. Yet, not all warranties cover the same issues. Make sure to read fine print. Some may have limitations that could surprise you later. Consider both aspects during your selection process.

Keep track of your needs and expectations. Sometimes, manufacturers may not clearly communicate their policies. It can lead to confusion later on. Take the time to ask questions. Clarifying doubts about pricing and warranty will serve you well. Your choice will significantly impact your operations. Thus, careful consideration is necessary.

Comparison of Ball Valve Manufacturers: Pricing and Warranty Options

Related Posts

-

Top Apollo Ball Valves for Optimal Performance and Reliability?

-

Top Tips for Choosing and Maintaining Your Recirculation Valve

-

Top Ball Valve Manufacturers to Watch in 2025 for Your Industry Needs

-

What is the Function of Saunders Valves in Fluid Control Systems?

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Top Gas Valves: Essential Types, Uses, and Buying Guide