Top Butterfly Valves Applications and Benefits Explained

Butterfly valves play a crucial role in various industries. They are widely used for fluid control due to their efficient design and operation. According to a report by MarketsandMarkets, the global butterfly valve market is projected to reach $6.1 billion by 2025. This growth highlights the importance of butterfly valves in sectors like water treatment, oil and gas, and power generation.

Operators often appreciate butterfly valves for their lightweight and compact design. These attributes allow for easier installation and maintenance. However, it is essential to understand that improper installation can lead to leaks. In fact, issues with sealing and wear can arise if the valves are not correctly aligned. These challenges prompt users to re-evaluate their valve selection process.

Moreover, butterfly valves offer excellent flow regulation capabilities. They can handle a wide range of temperatures and pressures. Yet, not all applications may benefit from butterfly valves. The specific requirements of each operation should guide the selection. This ensures optimal performance and longevity of the valves in use.

Overview of Butterfly Valves: Design and Functionality

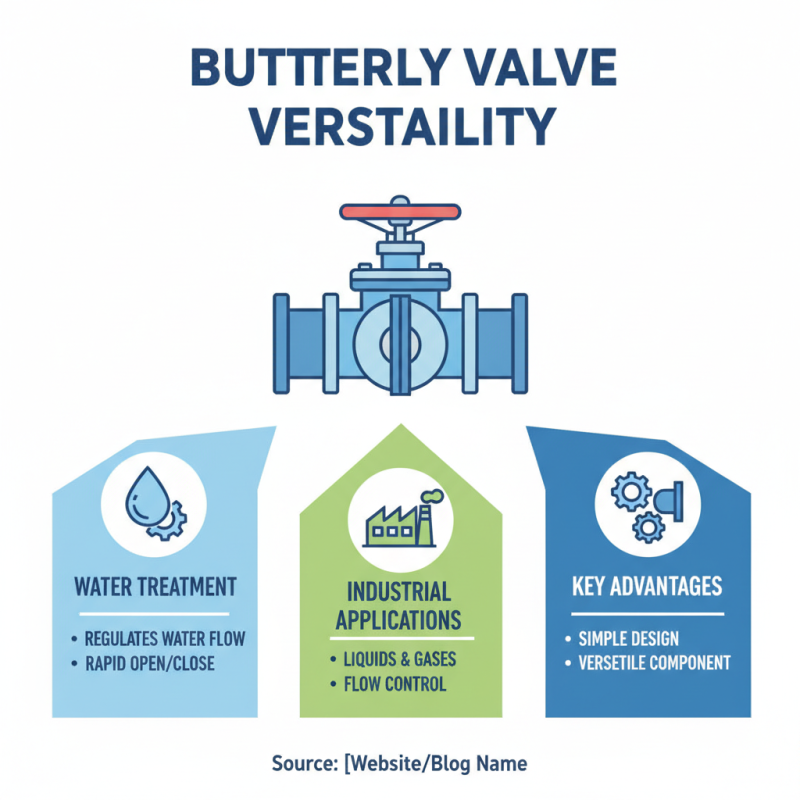

Butterfly valves are essential components widely used in various industries. Their design features a simple yet effective mechanism. A circular disc controls flow by rotating on a shaft. This allows precise flow regulation. The valve opens and closes with minimal effort, making it efficient in controlling process flow.

The functionality of butterfly valves lies in their versatility. They can be employed for throttling or on-off control. The compact design saves space, which is vital in many applications. However, this simplicity has limitations. They may not seal as tightly as other valve types. This can lead to leaking in high-pressure scenarios.

Installation is usually straightforward, but alignment is critical. Misalignment can lead to operational issues. Maintenance is also a concern, especially in harsh environments. Regular inspections are necessary to ensure reliability. Understanding these aspects helps users appreciate the balance between efficiency and potential drawbacks.

Common Applications of Butterfly Valves in Various Industries

Butterfly valves are versatile components used across various industries. They excel in applications involving the flow control of liquids and gases. In water treatment plants, butterfly valves help regulate water flow efficiently. Their simple design allows for rapid opening and closing, making them ideal for this environment.

In the chemical industry, these valves manage corrosive substances. They need to withstand harsh conditions and heavy usage. This requires careful selection and monitoring to prevent failures. Moreover, in HVAC systems, butterfly valves control airflow effectively. They maintain the desired temperature and reduce energy consumption.

Despite their advantages, butterfly valves can encounter issues like wear and tear. Regular inspection is essential to ensure optimal performance. Some users may overlook this important step, leading to operational disruptions. Understanding these applications helps industries choose the right systems for their needs.

Key Benefits of Using Butterfly Valves in Fluid Control Systems

Butterfly valves are essential in fluid control systems. They provide a simple and effective way to manage flow. These valves use a rotating disc to regulate the liquid or gas passing through. This design allows for quick operation and minimal pressure drop. It’s perfect for many applications like water supply and HVAC systems.

One major benefit of butterfly valves is their compact design. They occupy less space compared to other valves. This makes them easy to install in tight areas. Another advantage is their low weight, which reduces the need for heavy supporting structures. However, there can be challenges in high-pressure systems. Users must ensure they select the right materials to prevent wear and tear.

Moreover, the cost-effectiveness of butterfly valves cannot be overlooked. They are generally more affordable than other valve types. Additionally, they are easy to maintain and operate. While butterfly valves are efficient, improper installation can lead to leaks. Users should prioritize training for proper handling. Overall, the application of butterfly valves comes with both benefits and areas for improvement.

Comparison of Butterfly Valves with Other Valve Types

Butterfly valves play a significant role in various industrial applications. They are known for their simple design and efficient operation. Compared to other valve types, such as globe or gate valves, butterfly valves offer faster opening and closing times. This can enhance process control and improve system efficiency. Their compact design allows for more flexible installation, especially in tight spaces.

Butterfly valves are lighter than their counterparts. This reduces the structural load on pipelines. However, they might not provide the same seal quality as gate valves. For high-pressure systems, this can be a concern. Understanding the limitations is essential for making informed choices.

Tips: Always consider the medium flow. Butterfly valves are better for low-pressure systems. Think about maintenance needs; some valve types require more attention. Evaluate your application’s specific requirements carefully before selecting a valve type. Neglecting this could lead to inefficiencies in your system.

Best Practices for Installing and Maintaining Butterfly Valves

Installing and maintaining butterfly valves requires careful attention. Proper installation is crucial for ensuring optimal performance. One common mistake is improper alignment. When flanges are not aligned, it can lead to leaks and functional issues. Each valve must be positioned correctly to function smoothly. Using proper supports and tools can make a big difference.

Regular maintenance is essential. Inspecting valves for wear and tear will help identify problems early. Check for signs of corrosion or damage. It's important not to overlook the seals, as they can degrade over time. Cleaning valves periodically is also recommended to prevent buildup. This can ensure a longer lifespan and better efficiency.

Documentation should not be ignored. Keeping a record of maintenance activities can help track issues. Reflecting on past problems can guide better practices in the future. Sometimes, a thorough review of installation techniques is necessary. Mistakes can lead to costly repairs and downtime. Improvements in both installation and maintenance can lead to enhanced reliability of butterfly valves.

Butterfly Valves Applications and Benefits

This bar chart illustrates the top applications of butterfly valves across various industries, highlighting their usage in water treatment, chemical processing, HVAC, oil & gas, and food & beverage sectors. Each percentage reflects the proportion of applications found in these diverse fields.

Related Posts

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

Top Apollo Ball Valves for Optimal Performance and Reliability?

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

10 Essential Tips for Locating and Operating Your Natural Gas Shut Off Valve

-

How to Choose the Right Diaphragm Valve for Your Industrial Application

-

How to Choose the Right Gas Valves for Your Home and Business Needs