Top 10 Tips for Choosing the Best Valve Suppliers for Your Projects

In the ever-evolving industrial landscape, choosing the right valve suppliers is crucial for the success of any project involving fluid control systems. Experts emphasize that a well-informed decision can significantly impact operational efficiency and project outcomes. As John Anderson, a renowned expert in the valve industry, aptly states, "The choice of valve suppliers can make or break a project, influencing everything from cost-efficiency to system reliability." This underscores the importance of carefully evaluating potential suppliers in order to meet specific project requirements.

When navigating the complex marketplace of valve suppliers, it is essential to consider various factors such as quality, reliability, and customer service. With numerous options available, project managers and engineers must arm themselves with the right knowledge and strategies to identify suppliers who not only provide high-quality products but also understand the unique demands of their projects. As we delve into the top ten tips for selecting the best valve suppliers, we will explore how diligent research and thoughtful assessment can lead to partnerships that enhance project success and sustainability.

Identifying Your Project Requirements for Valve Suppliers

When embarking on a project that requires valve suppliers, the first step is to clearly identify your project requirements. Understanding the specific applications for which the valves will be used is crucial. For instance, a report by the Global Valve Market Research reveals that over 60% of industries, such as oil and gas, water treatment, and power generation, are highly sensitive to parameters like pressure, temperature, and fluid composition. This means that choosing suppliers who specialize in your project's particular environment can ensure longevity and reliability.

In addition to technical specifications, consider the volume and frequency of your valve needs. The same industry report suggests that more than 40% of projects experience delays due to inadequate supplier capacity or higher-than-expected lead times. Identifying whether your project requires bulk orders or custom designs will help in selecting a supplier that can accommodate your timeline and quality standards, ultimately enhancing project efficiency. Furthermore, evaluating supplier certifications and compliance with international standards can contribute significantly to achieving project goals while minimizing potential risks.

Researching the Market: Finding Potential Valve Suppliers

When embarking on a project that requires valve suppliers, the initial step in your procurement process is to conduct thorough market research. This involves not only identifying potential suppliers but also analyzing their capabilities and market standing. According to a recent report from MarketsandMarkets, the global industrial valve market is expected to reach $100 billion by 2025, driven by factors such as increased demand in the oil and gas sector and stringent safety regulations across various industries. This aligns with the need for selecting high-quality valve suppliers who can offer reliable products that meet industry standards.

To find potential valve suppliers, it’s crucial to utilize various research methods. Online platforms, industry trade shows, and technical publications can be invaluable resources. For instance, Global Industry Analysts report that up to 40% of procurement professionals rely on online directories and platforms to shortlist potential suppliers. Evaluating suppliers based on their certifications, previous project experiences, and customer reviews can also provide insights into their reliability. Informing your research with quantitative data and market trends can help you make informed decisions that lead to successful partnerships and ultimately, project success.

Top 10 Valve Suppliers: Market Research Insights

Evaluating Supplier Experience and Reputation in the Industry

When selecting valve suppliers for your projects, assessing their experience and reputation within the industry is crucial. A supplier’s experience often reflects their ability to address a variety of challenges and requirements that may arise during a project. An established supplier typically has a proven track record of delivering quality products and services, best practices honed over years of operation, and a wealth of knowledge about industry standards and regulations. This expertise can significantly enhance project efficiency and minimize delays, ensuring that technical specifications are met consistently.

In addition to experience, reputation plays a vital role in the decision-making process. A supplier known for reliability and integrity is invaluable, as it directly impacts the success of your projects. Researching reviews, testimonials, and case studies from previous clients can provide insight into a supplier's performance. Furthermore, participating in industry forums or seeking recommendations from peers can shed light on which suppliers are held in high regard. Choosing a supplier with a strong reputation not only offers peace of mind but can also foster a more collaborative and successful partnership, contributing to the overall quality of your projects.

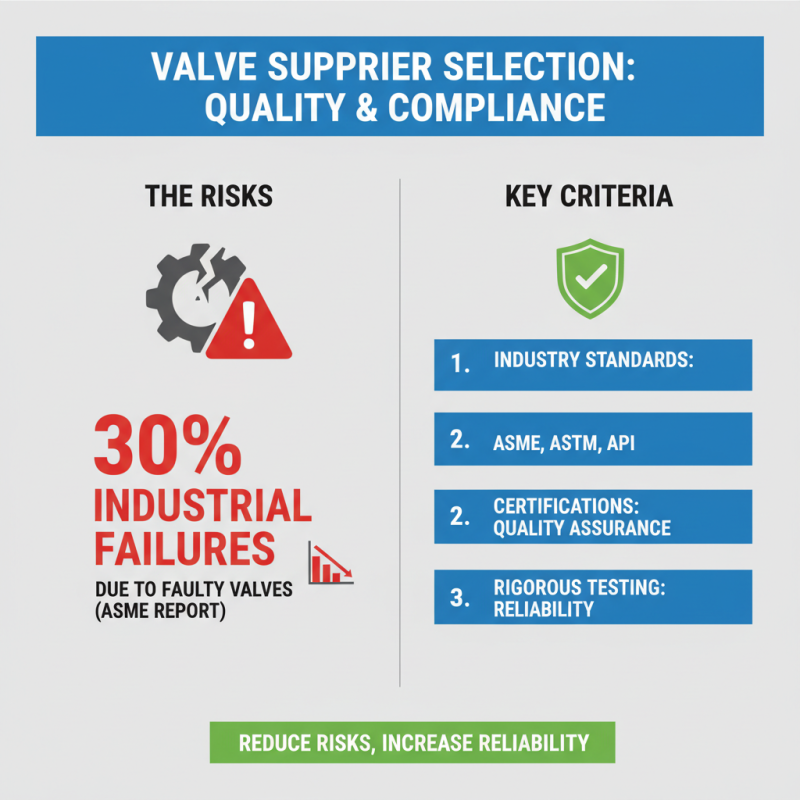

Comparing Product Quality and Compliance Standards

When selecting valve suppliers for your projects, it is crucial to emphasize product quality and compliance standards. According to a recent report from the American Society of Mechanical Engineers (ASME), nearly 30% of industrial failures are attributed to faulty valve performance. Thus, ensuring that the valves you source comply with recognized industry standards, such as ASME, ASTM, or API, can significantly reduce the risk of operational failures and associated costs. Suppliers who demonstrate a commitment to quality assurance, through certifications and rigorous testing protocols, can often provide more reliable products.

Additionally, compliance with environmental regulations is increasingly important in the selection of valve suppliers. A study by the International Organization for Standardization (ISO) indicated that over 70% of businesses see improved operational efficiency when working with suppliers adhering to ISO 9001 standards. This highlights that not only do compliant products enhance safety and performance, but they also contribute positively to the overall sustainability goals of projects. When evaluating suppliers, it is beneficial to examine their certifications, past compliance records, and adherence to international quality management systems, as these factors directly impact the reliability and longevity of the valves utilized in your operations.

Reviewing Customer Support and After-Sales Service Options

When selecting valve suppliers for your projects, the importance of robust customer support and after-sales service cannot be overstated. A recent industry report by MarketsandMarkets indicated that up to 60% of clients place high value on after-sales support when choosing a supplier, as it directly impacts project efficiency and long-term satisfaction. Effective customer support ensures that any issues arising post-purchase are swiftly addressed, which can mitigate potential delays in project timelines.

Furthermore, the capability of a supplier to provide timely technical assistance and product training is crucial. According to a study by Grand View Research, nearly 55% of organizations reported operational challenges due to inadequate technical support. Suppliers offering comprehensive training sessions or 24/7 customer service are often favored, as these services empower teams to maximize the performance of the products supplied. By paying close attention to the support infrastructure of potential valve suppliers, project managers can make informed decisions that contribute to the overall success of their projects.

Related Posts

-

Top 10 Valve Home Innovations to Watch in 2025

-

Top Tips for Choosing and Maintaining Your Recirculation Valve

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

How to Choose the Right Flow Check Valve for Your Application Needs