Exploring the Best Check Valve Options for 2026 Top Industry Trends?

In the ever-evolving world of industrial technology, check valves play a crucial role. They ensure fluid flow in the desired direction, protecting systems from backflow. As we look toward 2026, it's essential to explore the best check valve options available.

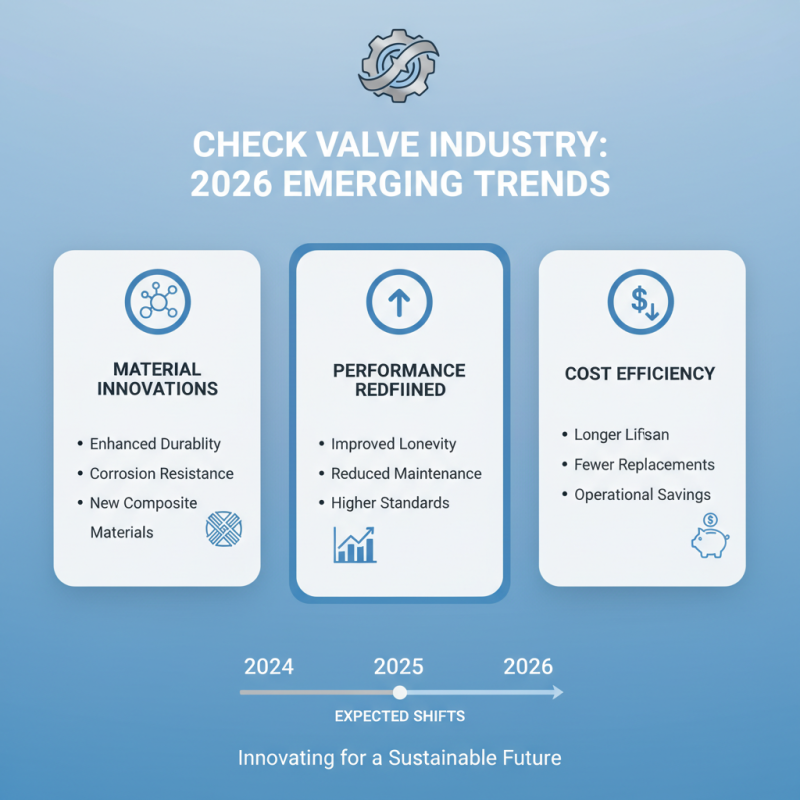

Several trends are emerging in the industry. Innovations in materials are making check valves more durable and efficient. Additionally, smart technologies are being integrated. These advancements help monitor valve performance in real-time. Yet, challenges remain. Manufacturers must balance cost and quality. Choosing the right type can be overwhelming.

Companies must consider various factors when selecting check valves. Understanding the specific application is vital. Each industry has unique requirements. There's no one-size-fits-all solution. As trends develop, it becomes clear: informed choices lead to better outcomes.

Defining Check Valves: Basics and Types for Industrial Applications

Check valves are essential in many industrial applications. They allow fluid to flow in one direction while preventing backflow. This simple mechanism is crucial for maintaining system integrity. There are various types of check valves, each suited for specific tasks.

Key Features to Consider When Selecting Check Valves

When selecting check valves, several key features should be taken into account. The material is crucial. Common options include plastic, metal, and rubber. Each of these materials offers different strengths. For example, metal valves often resist high pressure but may corrode. Plastic valves are lightweight but not ideal for extreme temperatures.

Another important feature is the valve type. There are several types available. Swing check valves, for instance, allow flow in one direction only. They are reliable but can be slower to respond. Spring-loaded checks are responsive. However, they may wear out more quickly. Consider the specific application to choose wisely.

Tips: Always check compatibility with your system. Ensure the valve can withstand the required pressure. Take note of the flow rate too. Too high a rate can cause issues.

Quality control is another aspect to think about. A poorly manufactured valve may leak. Regular maintenance is essential to avoid failures. You may find it necessary to replace them sooner than expected. Validate suppliers and their processes carefully for peace of mind.

Top Industries Utilizing Check Valves and Their Requirements

Check valves play a critical role in various industries. Their primary function is to allow fluid flow in one direction while preventing backflow. Industries such as water treatment, oil and gas, and pharmaceuticals heavily rely on check valves. According to a recent market analysis, the global check valve market is projected to grow by 5.4% annually through 2026. This indicates increasing demand across sectors.

In water treatment, reliable check valves are essential. They prevent contamination and protect pumps from damage. A study highlighted that 30% of water treatment facilities reported issues due to valve malfunction. This underlines the need for robust designs and regular maintenance. Similarly, the oil and gas industry prioritizes high-pressure check valves. Safety regulations require these valves to withstand extreme conditions. Yet, a surprising 20% of companies have not upgraded their aging systems.

Moreover, the pharmaceutical sector demands precise control. Check valves ensure sterile processes in drug manufacturing. An industry report showed that 25% of manufacturers faced challenges with valve leakage, risking product contamination. These statistics reflect an urgent need for enhanced reliability and innovation. Ensuring check valves meet industry standards is non-negotiable.

Exploring the Best Check Valve Options for 2026: Industry Usage Trends

Emerging Trends in Check Valve Technology for 2026

The check valve industry is evolving rapidly. In 2026, we expect several emerging trends that redefine performance standards. Innovations in materials will enhance durability and resistance to corrosion. New composite materials provide better longevity. They promise to reduce maintenance costs over time.

Smart check valves are also gaining attention. These valves integrate sensors and IoT technology. They allow real-time monitoring of flow rates and pressure levels. Users can detect issues before they escalate. However, this technology isn't foolproof. Reliability can vary, and setup costs may deter some.

Sustainability is becoming a priority, too. Eco-friendly designs are on the rise. Manufacturers focus on reducing energy consumption. However, the transition to greener materials presents challenges. Not all new materials perform equally. Balancing sustainability and performance is a key issue for the future.

Sustainability and Innovation in Check Valve Manufacturing Processes

The check valve industry faces evolving challenges in sustainability and innovation. As environmental awareness grows, manufacturers must adapt. Reports indicate that the global valve market could reach $87 billion by 2026, emphasizing the need for sustainable practices.

One effective approach is integrating advanced materials. Research shows that lightweight, corrosion-resistant composites can reduce production waste. These materials allow for longer product life cycles and decreased environmental impact. Investing in additive manufacturing presents another opportunity. This technology enables precise production with minimal waste, addressing the industry's resource-intensive nature.

However, not all innovations come without hurdles. Transitioning to new materials can require significant retooling and retraining. This process may disrupt current supply chains. Additionally, there are concerns about the initial costs of sustainable production. Manufacturers must weigh these factors against long-term benefits to make informed choices. As the industry shifts, the focus should remain on balancing profitability with environmental responsibility.

Exploring the Best Check Valve Options for 2026 Top Industry Trends? - Sustainability and Innovation in Check Valve Manufacturing Processes

| Check Valve Type | Material | Sustainability Feature | Innovative Manufacturing Process | Expected Market Growth (%) |

|---|---|---|---|---|

| Ball Check Valve | Stainless Steel | Recyclable | Additive Manufacturing | 8% |

| Swing Check Valve | Copper Alloy | Low Emission | CNC Machining | 6% |

| Lift Check Valve | Plastic | Biodegradable | Injection Molding | 10% |

| Dual Plate Check Valve | Ductile Iron | Energy Efficient | Robotic Assembly | 5% |

| Check Valve with Solenoid Actuator | Aluminum | Smart Technology Integration | 3D Printing | 12% |

Related Posts

-

Understanding the Importance of Shut Off Valves in Home Plumbing Systems: A Comprehensive Guide

-

Top 10 Valve Home Innovations to Watch in 2025

-

2025 How to Choose the Best Valve Products for Your Industry Needs

-

2026 Best Valve Products for Efficiency and Performance Review?

-

What is a Valve Home and How Does It Work?

-

What are the Best Mechanical Valves to Use in 2026?