Top 10 Benefits of Recirculation Valve for Efficient Performance

The recirculation valve plays a crucial role in enhancing system efficiency. It allows for the controlled flow of fluids. This control ensures optimal performance across various applications. Many industries benefit from implementing recirculation valves. These valves contribute to energy savings and lower operational costs.

In automotive systems, the recirculation valve improves engine efficiency. It can reduce emissions while maintaining power output. In HVAC systems, these valves help regulate refrigerant flow. This regulation provides consistent climate control. However, not all systems utilize recirculation valves effectively. Some designs overlook their importance, leading to potential inefficiencies.

Understanding the benefits of a recirculation valve is key. Each advantage can lead to improved performance. It’s essential to evaluate how these valves fit into your specific system. Sometimes, a simple upgrade can yield significant results. Reflecting on these factors is crucial for optimizing performance.

Understanding the Role of Recirculation Valves in Systems

Recirculation valves play a crucial role in various systems. They help maintain efficient performance by controlling the flow of fluids. When selected and implemented correctly, they improve the overall functionality. It’s fascinating how a small valve can have such a significant impact.

One key benefit is their ability to enhance pressure stability. Fluctuations in pressure can lead to inefficiencies. But with a recirculation valve, pressure remains more consistent. This promotes smoother operations, reducing wear on other components. However, not all systems benefit equally from this feature. Some may require adjustments for optimal performance.

Another aspect to consider is energy savings. A well-functioning recirculation valve can minimize energy waste. Unfortunately, if poorly designed or maintained, it might cause more harm than good. Operators must stay vigilant. Regular checks can ensure these valves operate at their best. It’s essential to strike a balance between efficiency and maintenance for lasting performance.

Enhanced Fluid Control and Stability with Recirculation Valves

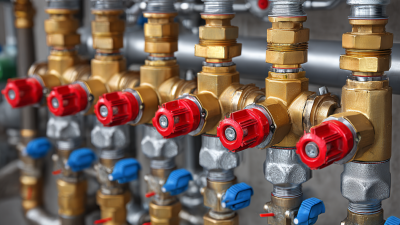

Recirculation valves play a crucial role in enhancing fluid control. These devices allow for the efficient regulation of fluid flow, minimizing disruptions. They enable a smoother operation by maintaining consistent pressure levels. A well-functioning recirculation valve ensures that systems avoid pressure fluctuations that can lead to inefficiencies. For instance, in hydraulic systems, improved stability is vital for performance.

Moreover, these valves can significantly reduce energy consumption. By recirculating fluid, they prevent unnecessary wastage. The fluid remains in motion, which helps maintain the desired temperature. However, improper valve selection can lead to problems. A valve that doesn't match the system's specifications may cause turbulence. This turbulence can disrupt flow patterns, negating the benefits of recirculation.

Regular maintenance is essential for optimal performance. Even minor wear and tear can affect fluid stability. Some users may overlook this aspect. Ignoring regular checks might lead to larger issues down the line. Balancing efficiency and practicality requires careful consideration. Recirculation valves, when properly utilized, truly enhance fluid control while providing stability in various applications.

Energy Efficiency Improvements through Recirculation Systems

Recirculation systems play a crucial role in improving energy efficiency across various industries. According to a report by the U.S. Department of Energy, implementing recirculation valves can reduce energy consumption by up to 30%. These systems streamline the flow of fluids, minimizing waste and ensuring optimal performance.

By using recirculation valves, industries can enhance their operational processes. These valves help maintain consistent temperatures and pressures, which are essential for efficient performance. In a recent study, it was found that companies utilizing these systems reported a 20% increase in overall efficiency. However, not all installations yield positive results. Some systems may require extensive monitoring and maintenance, raising questions about long-term stability.

Inadequate sizing or improper installation can lead to inefficiencies. It is important to consider the specific needs of each application. Many reports highlight that failing to analyze these factors may result in energy losses. Thus, reflecting on the installation process and ongoing management of recirculation valves is critical for maximizing savings.

Top 10 Benefits of Recirculation Valve for Efficient Performance

Reduced Wear and Tear on Equipment by Using Recirculation Valves

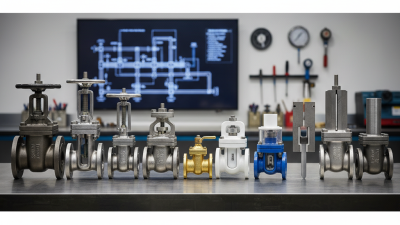

Recirculation valves play a crucial role in enhancing the lifespan of industrial equipment. A recent report by the Fluid Power Society indicates that proper use of recirculation valves can reduce wear and tear by up to 30%. This reduction is vital for maintaining optimal operation and efficiency, especially in high-pressure systems.

Utilizing recirculation valves helps maintain a stable flow rate within systems. It minimizes stress on components by preventing pressure surges. In systems where temperature fluctuation is a concern, these valves help ensure consistent performance. They stabilize the operating conditions, which is particularly beneficial in environments with varying loads.

However, the introduction of recirculation valves requires careful calibration. Improper settings could lead to inefficient operations or increased maintenance needs. The balance between efficiency and risk should be regularly evaluated. Regular assessments ensure that potential setbacks are addressed. Monitoring flow rates and conditions can highlight opportunities for improvement. It is essential to reflect on these areas to maximize the benefits of recirculation valves.

Top 10 Benefits of Recirculation Valve for Efficient Performance - Reduced Wear and Tear on Equipment by Using Recirculation Valves

| Benefit | Description | Impact on Equipment | Efficiency Improvement |

|---|---|---|---|

| Enhanced Equipment Longevity | Reduces stress on components by maintaining optimal flow. | Less frequent replacements. | Improves overall lifespan of machinery. |

| Reduced Maintenance Costs | Less wear leads to fewer repairs and lower expenses. | Direct savings on maintenance services. | Budget allocation can focus on other areas. |

| Increased Energy Efficiency | Optimizes fluid flow, reducing energy consumption. | Lower energy bills. | Enhances productivity without extra costs. |

| Consistent Performance | Maintains stable conditions for equipment operation. | Enhances reliability. | Minimizes downtime. |

| Reduced Noise Levels | Less turbulent flow leads to quieter operation. | Improves working conditions. | Enhances employee satisfaction. |

| Environmental Benefits | Lower emissions due to optimized efficiency. | Contributes to sustainability goals. | Enhances corporate image. |

| Improved Safety | Reduces risk of system failures. | Protects workers from hazards. | Encourages a safe work environment. |

| Versatility | Applicable in various industries and systems. | Adaptable to different setups. | Flexibility in operations. |

| Cost-effectiveness | Lowers operational costs through efficiency. | Maximizes resource allocation. | Enhances financial performance. |

| Simplified System Control | Easier monitoring and adjustments of flow rates. | Reduces operational complexities. | Facilitates better management. |

Environmental Benefits of Implementing Recirculation Valves

Implementing recirculation valves in industrial systems can lead to significant environmental benefits. Specifically, these valves help reduce energy consumption by ensuring optimal use of resources. According to industry reports, energy savings can reach up to 30% in certain applications. This efficiency not only lowers operational costs but also minimizes greenhouse gas emissions. In an era where climate change is a pressing concern, such measures can contribute significantly to sustainability goals.

Moreover, recirculation valves facilitate better water management in processes that require water circulation. For instance, they can prevent water wastage, which is crucial in regions facing water scarcity. Studies show that these systems can reduce water usage by as much as 20%. However, the installation process can be complex and may require adjustments to existing systems. Some facilities experience challenges in adapting to these new setups, and this should not be overlooked.

Additionally, the implementation of these valves supports stricter compliance with environmental regulations. Companies may face challenges in ensuring their systems are up to code. Reports highlight that failure to comply can result in heavy fines and operational shutdowns. Thus, while the benefits are clear, organizations must invest time and resources to manage these transitions effectively. Implementing recirculation valves can pave the way for a greener future, but it requires commitment and careful planning.

Related Posts

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

How to Choose the Right Gas Valves for Your Home or Business Needs

-

Top 10 Saunders Valves Benefits You Should Know

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Top 10 Gate Valves Types and Their Best Applications for Your Projects