Discover the Benefits of Using Butterfly Valves in Industrial Applications

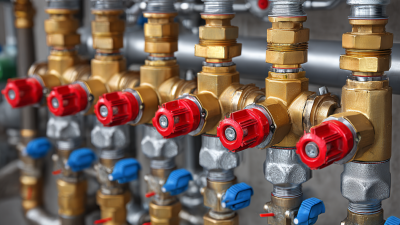

In the realm of industrial applications, the significance of using butterfly valves cannot be overstated.

These valves are renowned for their efficiency, reliability, and simplicity, making them a popular choice across various sectors, including water treatment, oil and gas, and HVAC systems. According to a recent market research report by Mordor Intelligence, the global butterfly valve market is poised to grow at a CAGR of 5.4% from 2021 to 2026, highlighting the increasing adoption of these valves in industrial settings.

These valves are renowned for their efficiency, reliability, and simplicity, making them a popular choice across various sectors, including water treatment, oil and gas, and HVAC systems. According to a recent market research report by Mordor Intelligence, the global butterfly valve market is poised to grow at a CAGR of 5.4% from 2021 to 2026, highlighting the increasing adoption of these valves in industrial settings.

Butterfly valves offer several advantages, such as lightweight design, quick operation, and cost-effectiveness, which contribute to their rising demand. By understanding how to effectively utilize butterfly valves, industries can optimize their operations, enhance flow control, and reduce maintenance costs. This article aims to delve into the benefits of butterfly valves and provide insights on their proper implementation in various industrial applications.

Key Advantages of Butterfly Valves in Process Control Systems

Butterfly valves have emerged as a prominent choice in process control systems due to their unique design and operational efficiency. One of the key advantages is their ability to provide quick and precise flow control, making them ideal for applications requiring rapid response. These valves minimize pressure drops, ensuring that systems operate smoothly while conserving energy. Additionally, their lightweight construction allows for easier installation and maintenance, further enhancing operational efficiency in industrial settings.

Tips: When considering butterfly valves for your process control systems, ensure that the selected valve is compatible with the specific fluid characteristics and operating conditions. Regular maintenance checks can also prolong the lifespan of the valves and maintain optimal performance.

Moreover, butterfly valves are often more cost-effective compared to traditional gate or globe valves. Their compact design requires less space, making them suitable for installations where space is at a premium. With various materials available, including metal and plastic, they can be tailored to withstand different chemical environments, ensuring durability and reliability in diverse industrial applications.

Tips: Evaluate the materials used in butterfly valves to ensure they are suitable for your particular application, especially in corrosive or high-temperature environments. Investing time in the selection process can lead to significant long-term benefits.

How Butterfly Valves Enhance Energy Efficiency in Industrial Settings

Butterfly valves are increasingly recognized for their role in enhancing energy efficiency across various industrial applications. According to the latest market research, the importance of these valves is underscored by the ongoing growth trends within the industrial valves market. The High Performance Butterfly Valve Market is projected to drive efficiencies and innovation in flow control, further establishing butterfly valves as pivotal components in energy-driven sectors.

The optimization of energy consumption in industrial settings can be significantly attributed to the operational characteristics of butterfly valves. These valves are lightweight, capable of quick operation, and provide a tight seal, which minimizes the energy loss associated with fluid flow. As industries strive for more sustainable practices, integrating butterfly valves not only meets operational demands but also aligns with regulatory pressures for energy efficiency. Custom Market Insights projects that enhanced efficiency measures will contribute significantly to the global demand for advanced valve solutions, reflecting a CAGR of 8.8% through 2034 in related markets. Such data highlights the growing recognition of equipment that supports sustainability efforts.

Discover the Benefits of Using Butterfly Valves in Industrial Applications

| Application Area | Energy Efficiency (%) | Cost Savings ($) | Maintenance Frequency (months) |

|---|---|---|---|

| Water Treatment | 20% | 500 | 12 |

| Chemical Processing | 15% | 750 | 8 |

| HVAC Systems | 18% | 600 | 10 |

| Oil & Gas | 22% | 1000 | 6 |

| Food & Beverage | 25% | 800 | 9 |

Comparative Analysis: Butterfly Valves vs. Other Valve Types

When comparing butterfly valves to other valve types, their unique design offers several advantages that make them suitable for various industrial applications. Unlike gate or globe valves, butterfly valves operate using a quarter-turn mechanism, which allows for quick and efficient throttling and isolation. This design reduces the torque required for operation, making them easier to handle and maintain. Additionally, butterfly valves have a compact structure, saving valuable space in pipeline systems while providing reliable flow control.

Another significant aspect of butterfly valves is their versatility across different applications. While other valve types, such as ball and check valves, may excel in specific scenarios, butterfly valves are particularly well-suited for large flow applications in water treatment, HVAC systems, and chemical processing. Their ability to manage high flow rates while maintaining low-pressure drop enhances overall system efficiency. Furthermore, butterfly valves are often constructed with lightweight materials, which can reduce the load on piping and support structures, making them an attractive choice for modern industrial facilities.

Best Practices for Selecting and Maintaining Butterfly Valves

When selecting butterfly valves for industrial applications, it is essential to consider several key factors that ensure optimal performance and longevity. According to a report by the International Journal of Engineering Research and Technology, proper sizing of the valve is crucial; an ill-fitted valve can lead to flow restrictions and increased wear on the system components. It's recommended to analyze the pressure and temperature conditions of your application to choose the appropriate valve material—options range from PVC and carbon steel to stainless steel, each suitable for different environments.

Maintenance practices significantly impact the efficiency and lifespan of butterfly valves. Regular visual inspections can help identify potential issues such as leaks or corrosion early on. A study by the Valve Manufacturers Association indicates that implementing a routine maintenance schedule can reduce valve failure rates by up to 30%. Moreover, lubricating the valve's shaft and seals as part of a regular maintenance plan is vital to prevent seizing and ensure smooth operation.

**Tips:** Always verify the manufacturer's specifications for torque settings when installing the valves. Additionally, ensure that the valve is operated within its designated pressure limits to prolong its service life. Finally, documenting maintenance activities can assist in tracking performance trends and identifying potential problems before they escalate.

Benefits of Using Butterfly Valves in Industrial Applications

This chart displays the percentage of various benefits of using butterfly valves in industrial applications, highlighting their effectiveness and maintenance practices.

Innovative Applications of Butterfly Valves in Modern Industries

Butterfly valves have emerged as a pivotal component in modern industrial applications, significantly transforming operational efficiency across various sectors. Particularly in the water and wastewater treatment industries, butterfly valves can provide effective control over flow rates and pressure management. According to a report from MarketsandMarkets, the butterfly valve market is projected to reach USD 8.1 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.6%. This highlights the increasing adoption of these valves in applications like chemical processing and HVAC systems due to their reliability and performance efficiency.

In the oil and gas sector, the innovative use of butterfly valves for natural gas transport and refining processes has become increasingly prominent. Their lightweight design allows for easier installation and maintenance, while their space-saving characteristics make them ideal for tight installations. Additionally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) emphasizes using valves that reduce the risk of leaks and ensure safety. With rigorous demands for efficiency and safety in industrial operations, butterfly valves are positioned to address these challenges, optimizing performance while adhering to strict regulatory standards.

Related Posts

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Understanding the Importance of Shut Off Valves in Home Plumbing Systems: A Comprehensive Guide

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights