Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

In the realm of industrial applications, the significance of fluid control cannot be understated, with the 4 check valve emerging as a crucial component in a variety of systems. According to a recent report by MarketsandMarkets, the global valve market is projected to reach $88.7 billion by 2025, driven by increasing investments in the oil and gas, water and wastewater, and power generation sectors. The 4 check valve, specifically designed to prevent backflow while allowing forward flow, enhances system efficiency and reliability. Its ability to operate effectively across diverse conditions makes it an indispensable asset. Recent expert analyses indicate that industries utilizing 4 check valves have experienced up to a 30% reduction in maintenance costs, further cementing their role in modern industrial setups. As we delve deeper into the benefits and expert insights surrounding the 4 check valve, it becomes clear why it is increasingly favored in today’s competitive market landscape.

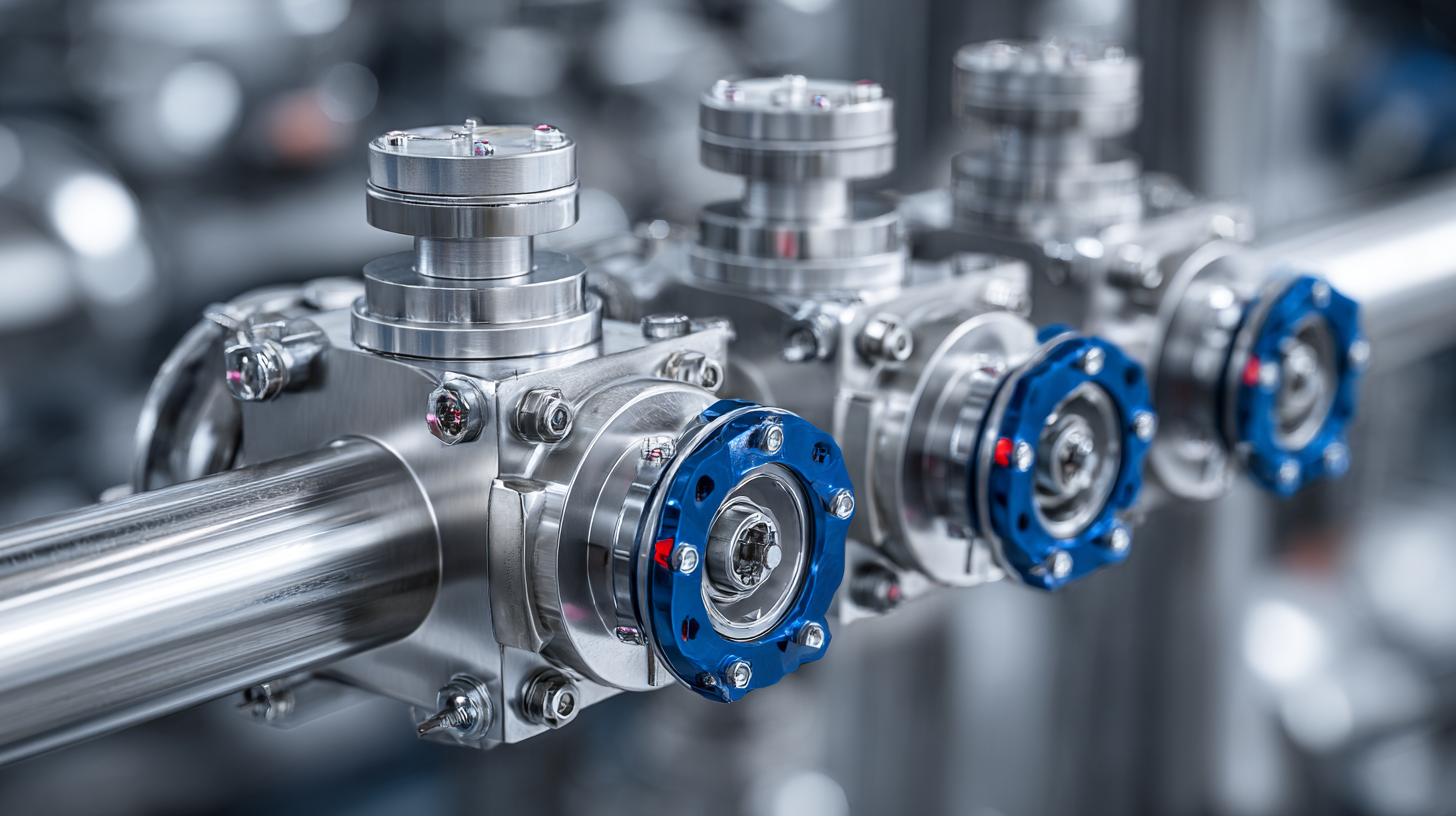

Understanding the Functionality of 4 Check Valves in Industrial Settings

In industrial applications, the functionality of 4 check valves plays a pivotal role in maintaining system efficiency and reliability. These valves are primarily designed to prevent backflow within a piping system, ensuring that fluids flow in only one direction. According to a recent report by Research and Markets, the global check valve market is projected to reach USD 5.3 billion by 2026, reflecting the rising demand in various industries such as oil and gas, water and wastewater, and power generation. This growth underscores the critical role that check valves, particularly the 4 check variety, serve in safeguarding equipment and optimizing operational processes.

Additionally, expert insights reveal that the utilization of 4 check valves can significantly reduce the risk of system malfunctions caused by reverse flow. Data from the American Society of Mechanical Engineers indicates that improper fluid handling can lead to up to 30% of maintenance costs in industrial operations. By employing 4 check valves, industries can not only enhance safety but also achieve improved energy efficiency, reducing costs linked to system repairs and downtime. Their robust design and reliability make them an indispensable component in high-pressure applications and complex piping networks, ensuring the smooth and safe transport of various fluids.

Unveiling the Benefits of 4 Check Valve in Industrial Applications

| Dimension | Specification | Material | Application | Key Benefit |

|---|---|---|---|---|

| 2 Inch | 150 PSI | Stainless Steel | Water Treatment | Prevents Backflow |

| 3 Inch | 200 PSI | Brass | Chemical Processing | Durability |

| 4 Inch | 250 PSI | PVC | Wastewater | Corrosion Resistance |

| 6 Inch | 300 PSI | Aluminum | Oil Extraction | Lightweight |

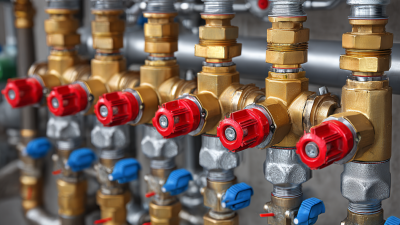

Key Benefits of Implementing 4 Check Valves in Various Industries

Implementing 4 check valves in industrial applications offers a multitude of benefits that can significantly enhance operational efficiency across various sectors. According to a recent industry report by the Hydraulic Institute, the use of check valves can reduce system failures by up to 30%, thereby decreasing maintenance costs and improving the longevity of equipment. These valves help prevent backflow, ensuring that processes remain uninterrupted and that fluid dynamics are maintained, which is crucial in sectors like oil and gas, pharmaceuticals, and water treatment.

Moreover, the versatility of 4 check valves allows them to be utilized in a range of applications, from managing high-pressure systems to supporting low-flow processes. Data from the American Society of Mechanical Engineers indicates that implementing check valves can improve system reliability by 25%, ensuring that operations run smoothly without unexpected downtimes. This reliability is essential for industries striving for high productivity and seamless supply chain management.

**Tip:** When selecting a check valve, consider the specific flow direction and pressure requirements of your system. This ensures optimal performance and minimizes potential leaks. Additionally, regular inspection of these valves can help identify wear and tear early, avoiding costly production interruptions. Always consult with an industry expert to tailor the best solution for your unique operational needs.

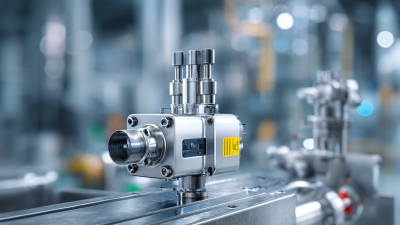

Expert Insights on Selecting the Right 4 Check Valve for Different Applications

When selecting the right 4 check valve for various industrial applications, it's essential to consider factors such as pressure rating, material compatibility, and flow direction. According to industry standards, the right choice can significantly enhance system performance and reliability. A report from the Fluid Control Institute indicates that properly selected check valves can reduce maintenance costs by up to 15%, a substantial saving for any industrial operation. This is particularly vital in sectors like water treatment, chemical processing, and oil and gas, where failure to choose an appropriate valve can lead to catastrophic leaks and extensive downtimes.

Moreover, expert insights suggest that different applications require specific designs; for instance, spring-loaded check valves are ideal for fluctuating pressures, while dual-plate designs are better suited for low-pressure systems. Recent studies show that optimizing valve selection based on application can boost operational efficiency by as much as 20%, underscoring the importance of expert guidance in this process. With advances in materials and design, industries can maximize performance and ensure safety through informed valve choices, aligning with the growing emphasis on efficiency in industrial applications.

Common Challenges and Solutions in Using 4 Check Valves in Industry

In industrial applications, the use of 4 check valves presents several common challenges that can impact operational efficiency. One major issue is the potential for valve failure due to debris or sediment buildup. In environments where fluids carry particulates, these materials can hinder the valve's performance, leading to backflow or leakage. Regular maintenance and the installation of pre-filters are effective solutions to mitigate this problem, ensuring the valve remains fully operational and reducing downtime.

Another challenge relates to installation and orientation concerns. 4 check valves must be installed correctly to function properly; improper installation can result in inadequate sealing and increased wear. To address this, industries should prioritize training and comprehensive installation guidelines, which will help in minimizing errors. Additionally, utilizing valves with visual indicators can assist operators in confirming correct alignment and functionality at a glance, further enhancing reliability and performance in complex systems.

Benefits and Challenges of 4 Check Valves in Industrial Applications

Future Trends and Innovations in 4 Check Valve Technology for Industrial Use

The future of 4 check valve technology in industrial applications is poised for significant transformation driven by emerging trends and innovations. With the focus on sustainability, advancements in materials and design are leading to the development of more efficient and durable check valves. These innovations not only enhance performance but also contribute to energy savings and reduced maintenance costs, aligning with the growing emphasis on eco-friendly industrial practices.

Opportunities in this sector are considerable, especially as industries shift towards renewable energy sources. The integration of 4 check valves in systems like solar and wind energy contributes to enhanced reliability and efficiency. However, challenges such as the need for standardization and adapting to new materials must be addressed. The adoption of IoT solutions for monitoring and controlling valve performance can help mitigate these challenges and drive efficiency.

Tips: When considering upgrades or new installations, evaluate the compatibility of 4 check valves with existing systems and seek expert insights for optimized performance. Regular maintenance and monitoring through IoT can significantly prolong the lifespan of your valves while ensuring operational efficiency.

Related Posts

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Understanding the Importance of Shut Off Valves in Home Plumbing Systems: A Comprehensive Guide

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide