How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

In the ever-evolving landscape of industrial automation, the integration of advanced technologies is paramount for enhancing efficiency and productivity. Among these innovations, the automatic valve stands out as a pivotal component that revolutionizes the management of fluid control systems. This comprehensive guide delves into the transformative role of automatic valves in automating processes across various industries, from manufacturing to energy and beyond. By eliminating the need for manual intervention, these intelligent devices not only streamline operations but also reduce the risk of human error and improve safety protocols.

Furthermore, we will explore the different types of automatic valves, their applications, and practical tips for optimizing their performance within an automation framework. As we navigate the intersection of technology and industry, understanding the advantages and complexities of automatic valves becomes essential for engineering professionals seeking to harness the full potential of industrial automation systems.

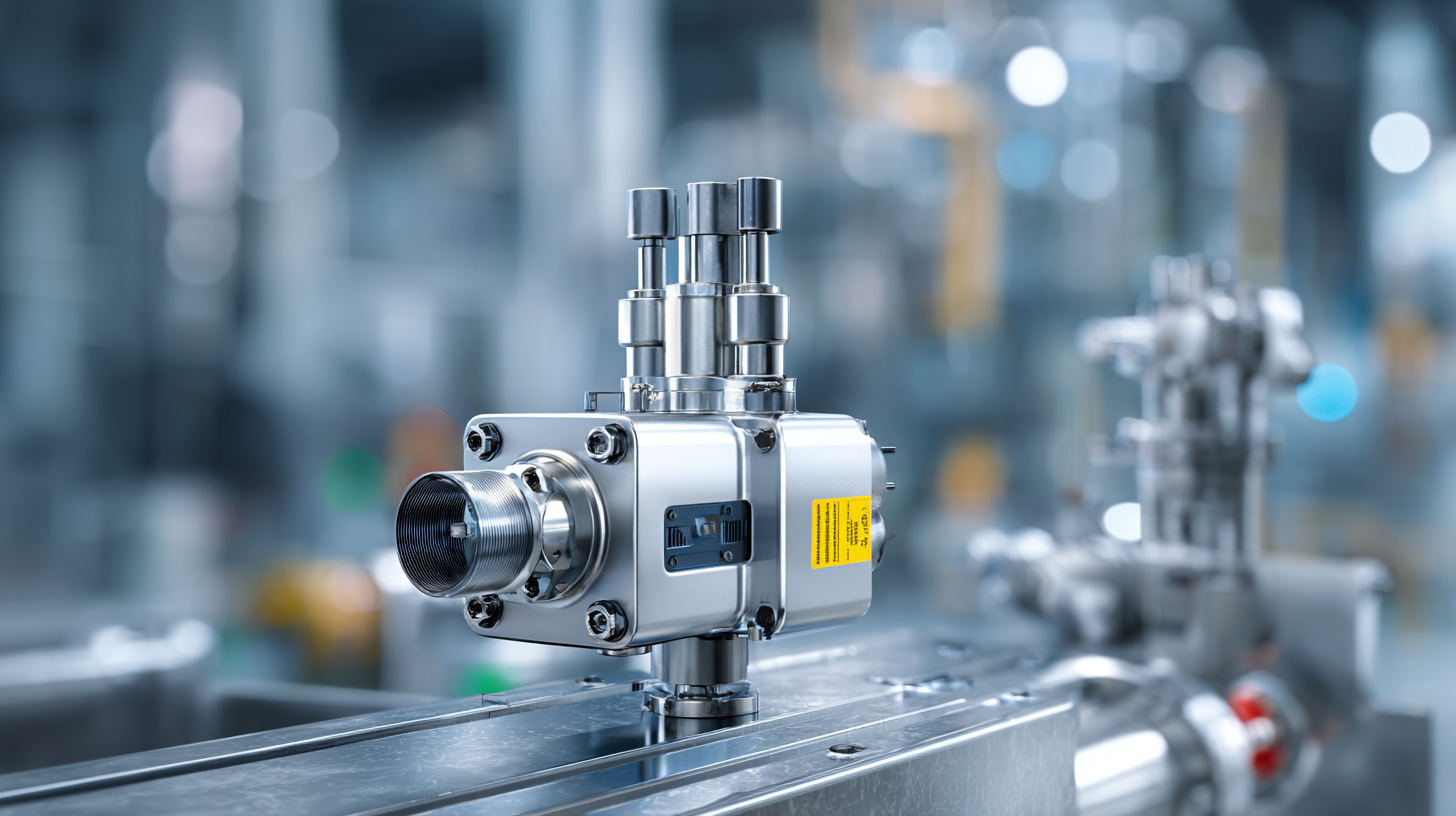

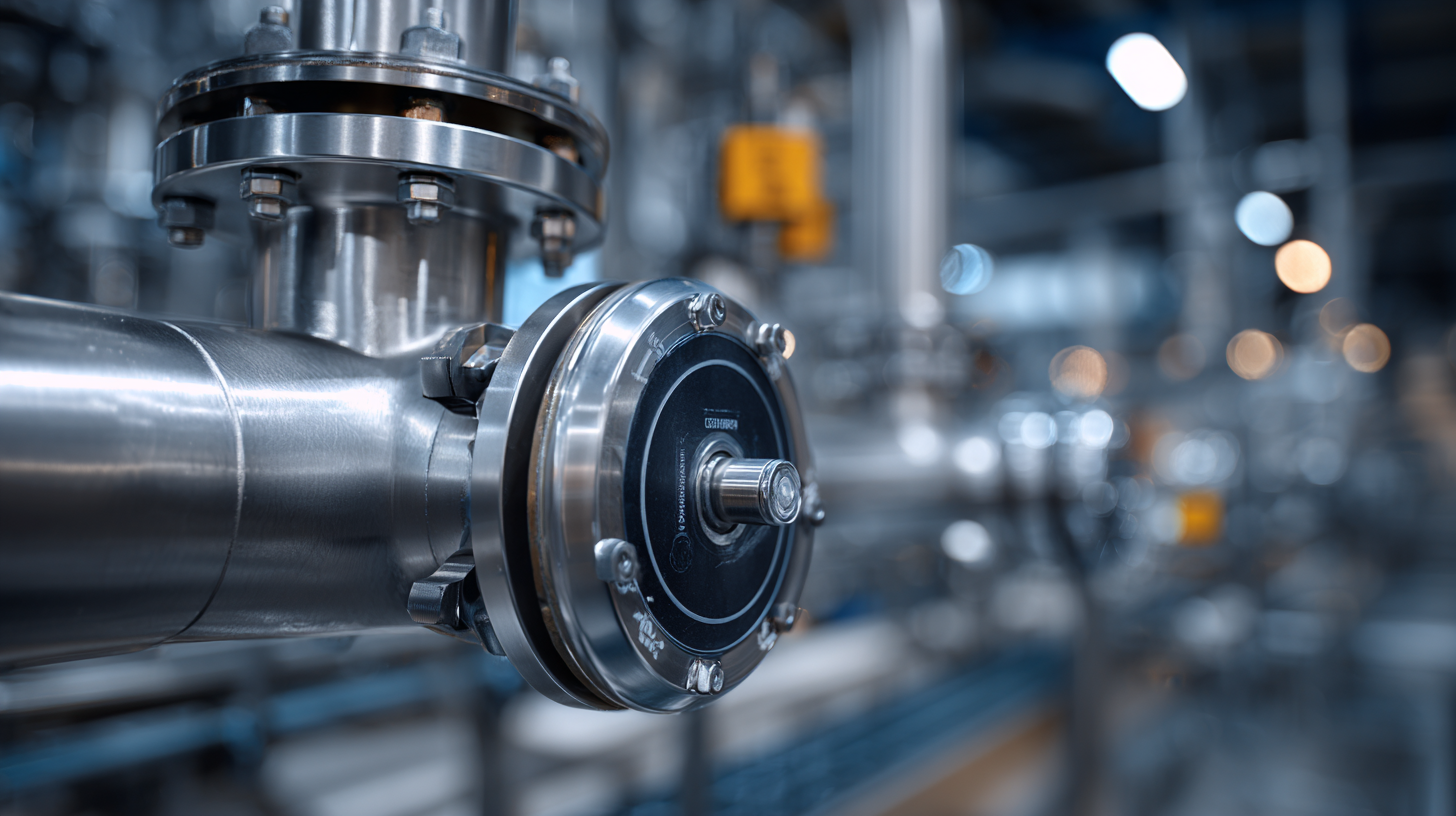

Understanding Automatic Valves: Types and Mechanisms in Industrial Settings

Automatic valves play a crucial role in industrial automation by controlling the flow of fluids with precision and reliability. Understanding the various types of automatic valves is essential for optimizing operations. The most common types include globe valves, ball valves, butterfly valves, and check valves, each designed for specific applications. Globe valves are ideal for regulating flow, while ball valves offer quick shut-off capabilities. Butterfly valves are commonly used in large volume applications due to their lightweight design, and check valves prevent backflow, thereby protecting equipment from damage.

The mechanisms behind these valves also vary significantly, enhancing their utility in different industrial settings. Electric, pneumatic, and hydraulic actuators drive many automatic valves, allowing for remote or automated control. Electric actuators provide precise positioning and are typically used in environments requiring tight control. Pneumatic actuators, on the other hand, offer rapid actuation and are preferred in applications needing quick response times. Hydraulic actuators are used where high force is necessary, making them suitable for heavy-duty operations. Together, these types and their mechanisms revolutionize industrial automation by improving efficiency, safety, and reliability in fluid control processes.

Importance of Automatic Valves in Industrial Automation

This chart illustrates the distribution of different types of automatic valves used in various industrial settings, highlighting their importance in enhancing efficiency and safety.

Benefits of Implementing Automatic Valves in Automation Systems

Automatic valves have become an integral part of modern industrial automation systems,

providing significant benefits that enhance efficiency and reliability. According to a report by MarketsandMarkets,

the automatic valve market is expected to reach $5.8 billion by 2025, growing at a CAGR of 6.8%.

This growth underscores the increasing recognition of the advantages that automatic valves bring to various industries,

including reduced labor costs and minimized human error.

One of the primary benefits of implementing automatic valves is improved process control.

These valves enable precise flow regulation and can respond to changing conditions in real-time, leading to enhanced operational efficiency.

A study published by the ISA (International Society for Automation) highlights that companies adopting automatic valves have reported a

20% increase in process efficiency due to better control and automation of fluid flow.

Furthermore, automatic valves can be integrated with smart technologies, facilitating predictive maintenance and allowing

for remote monitoring, which further decreases downtime and maintenance costs. This seamless integration is a key driver in the transformation

of industrial operations, illustrating the vital role that automatic valves play in today’s automation landscape.

Key Technologies Driving the Evolution of Automatic Valves

Automatic valves are at the forefront of industrial automation, driven by key technologies that enhance efficiency and reliability in various applications. One significant advancement is the integration of smart sensors, which allow for real-time monitoring and control of valve operations. These sensors can detect changes in pressure, temperature, and flow, enabling predictive maintenance and reducing downtime. By providing data analytics capabilities, smart sensors facilitate informed decision-making and optimize system performance.

Another crucial technology propelling the evolution of automatic valves is the development of advanced actuators. Electric and pneumatic actuators have become increasingly sophisticated, allowing for precise control over valve movements. This precision not only enhances the operational efficiency of industrial processes but also improves safety by minimizing the risk of human error. In addition, the adoption of IoT (Internet of Things) connectivity allows automatic valves to be integrated into broader automation systems, enabling seamless communication among various components in a facility. These technologies collectively contribute to a smarter, more efficient industrial landscape.

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

| Technology | Application | Benefits | Market Trends |

|---|---|---|---|

| Electromagnetic Valves | Automated flow control in chemicals | High precision, fast response time | Growing demand for advanced process control |

| Pneumatic Valves | Control systems in food and beverage | Reliable operation, ease of integration | Increased automation in production lines |

| Ball Valves | HVAC systems and oil refining | Minimal pressure drop, compact design | Rising focus on energy efficiency |

| Solenoid Valves | Water treatment facilities | Automated operation, low power consumption | Innovation towards smart water solutions |

| Check Valves | Pipelines in oil and gas | Prevent backflow, enhance system safety | Increased regulation and safety standards |

Maintenance and Troubleshooting for Automatic Valve Systems

Automatic valve systems play a crucial role in enhancing operational efficiency within various industrial applications. Regular maintenance and troubleshooting of these systems are paramount for ensuring their optimal performance. According to industry reports, up to 30% of downtime in industrial processes can be attributed to valve malfunctions. Implementing a routine maintenance schedule not only prolongs the lifespan of the valves but also significantly reduces the risk of operational failures. Key strategies include regular inspection of valve seals, monitoring actuator performance, and ensuring proper calibration of automated controls.

Moreover, as seen in modern applications such as irrigation and aquaculture, automatic valve systems can aid in mitigating operational challenges. Automated irrigation systems, for instance, have been reported to use 20-30% less water compared to traditional methods by optimizing water distribution. Additionally, submersible technologies in fish farming address surface-related problems, showcasing the adaptability of automatic valves in diverse environments. Understanding these technologies and employing effective troubleshooting methods can lead to enhanced reliability and efficiency in industrial operations.

Future Trends in Automatic Valves and Their Impact on Industrial Automation

The future of industrial automation is increasingly intertwined with advancements in automatic valve technology. According to a recent report by MarketsandMarkets, the global automatic valve market is projected to grow from $12.3 billion in 2023 to $17.6 billion by 2028, reflecting a compound annual growth rate (CAGR) of 7.6%. This growth is largely driven by the rising demand for process optimization and operational efficiency in various sectors, including oil and gas, water treatment, and food and beverage industries.

Emerging trends indicate that smart automation solutions, including IoT-enabled valves, will significantly enhance the monitoring and control of industrial processes. A study by Grand View Research highlights that the integration of AI and machine learning with automatic valve systems can lead to up to 30% reductions in energy consumption. Furthermore, real-time data analytics capabilities allow for predictive maintenance, minimizing downtime and extending the lifespan of equipment. As industries adopt these technologies, the role of automatic valves will continue to evolve, becoming a crucial component of smart factories and energy-efficient operations.