Why You Should Choose Automatic Valves for Your Industrial Applications

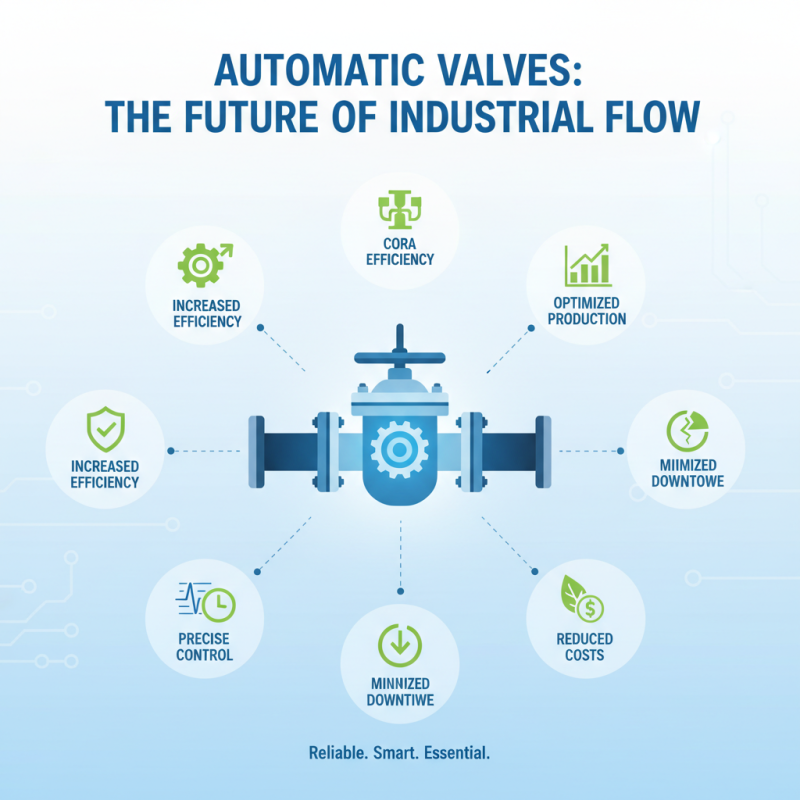

In the realm of industrial applications, the choice of valves can significantly impact operational efficiency, safety, and cost-effectiveness. Among the various options available, automatic valves stand out due to their numerous advantages and adaptability to a range of processes. Unlike manual valves, which require human intervention for operation, automatic valves enhance system automation by providing real-time control and responsiveness to changing conditions. This not only minimizes human error but also streamlines workflows, allowing for optimized production and reduced downtime.

The demand for automatic valves is increasing as industries strive to improve their processes and harness the benefits of automation. These valves are designed to operate based on specific parameters such as pressure, flow rate, or temperature, ensuring that systems function within their optimal ranges. By incorporating automatic valves into industrial setups, organizations can achieve higher levels of precision in managing fluid dynamics, contributing to better resource management and sustainability. Ultimately, investing in automatic valves represents a forward-thinking approach that aligns with the ongoing trends towards automation and efficiency in industrial environments.

Benefits of Automatic Valves in Industrial Settings

Automatic valves are becoming increasingly popular in industrial applications due to their numerous benefits. One of the primary advantages is enhanced efficiency. These valves can operate without manual intervention, enabling more precise control over fluid flow and pressure. This automation reduces the likelihood of human error, leading to consistent performance and optimal system operation. As a result, industries that implement automatic valves can experience lower operational costs and increased productivity.

Another significant benefit of automatic valves is their ability to improve safety in industrial environments. By minimizing manual processes, the risk of accidents related to valve operation is significantly reduced. Additionally, automatic valves can be equipped with monitoring systems that provide real-time data, allowing for immediate responses to any irregularities in the system. This proactive approach not only protects personnel but also safeguards equipment and processes from potential damage.

In summary, the adoption of automatic valves in industrial settings offers both operational efficiency and enhanced safety, making them a vital component in modern industrial applications.

Types of Automatic Valves and Their Applications

Automatic valves play a crucial role in various industrial applications, owing to their efficiency and reliability. Different types of automatic valves serve specific purposes across multiple sectors. For example, ball valves are prevalent in water treatment facilities due to their tight sealing and ability to handle high pressures, which is confirmed by a report from the Global Market Insights that predicts the ball valve market will exceed $12 billion by 2026. Similarly, globe valves are often used in steam systems because they provide excellent throttling capabilities, enhancing system control and efficiency.

In chemical processing, diaphragm valves are favored for their ability to handle corrosive materials safely, as reported by Research and Markets, which states that the demand for diaphragm valves is expected to grow significantly, emphasizing their importance in maintaining safety standards. These valves minimize the risk of contamination and provide ease of maintenance, making them vital in industries dealing with sensitive compounds.

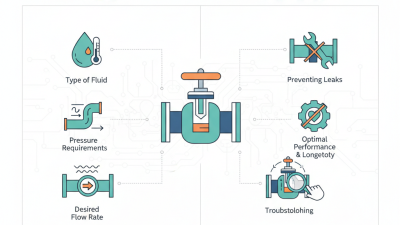

Tips: When selecting an automatic valve, consider the specific fluid types, pressure conditions, and the operational environment. It's essential to ensure that the materials used in the valve construction are compatible with the substances being handled. Regular maintenance checks will also help in sustaining the longevity and performance of automatic valves in your applications, reducing unexpected downtime.

Why You Should Choose Automatic Valves for Your Industrial Applications

| Type of Automatic Valve | Application Area | Benefits |

|---|---|---|

| Ball Valve | Water Supply Systems | Quick opening and closing, low resistance |

| Gate Valve | Oil and Gas Pipelines | Minimal pressure drop, suitable for on/off service |

| Globe Valve | Chemical Processing | Good throttle control, moderate pressure drop |

| Check Valve | Pumping Stations | Prevents backflow, enhances system reliability |

| Solenoid Valve | Automated Control Systems | Fast and flexible control, energy efficient |

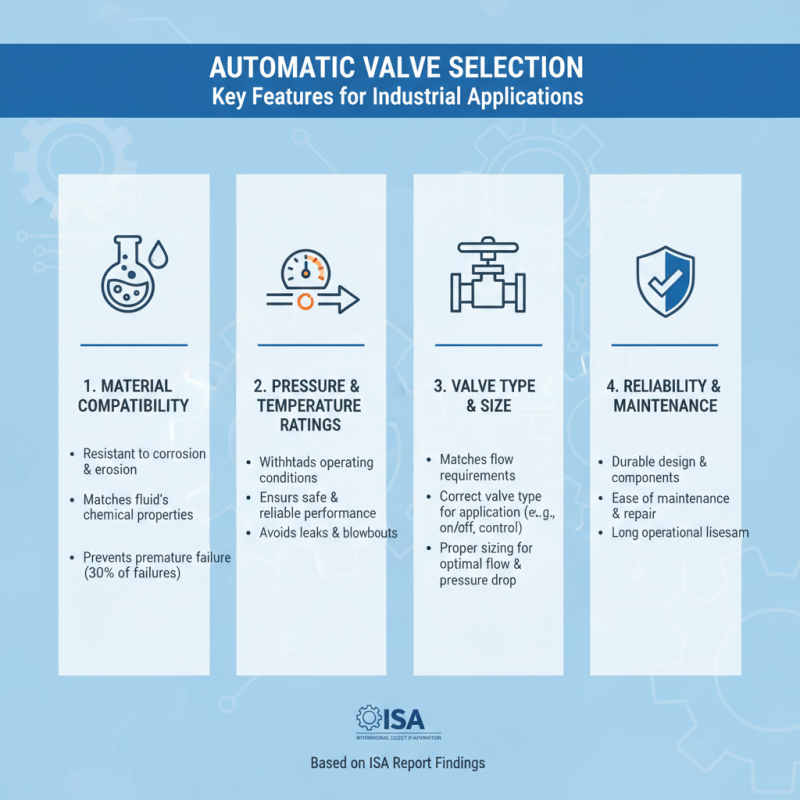

Key Features to Consider When Selecting Automatic Valves

When selecting automatic valves for industrial applications, several key features should be considered to ensure optimal performance and reliability. One of the primary aspects is the valve's material compatibility with the media it will handle. According to a recent report by the International Society of Automation, approximately 30% of valve failures in industrial settings are attributed to material corrosion or erosion. Thus, choosing valves made from materials that can withstand the chemical and physical properties of the processed fluids is crucial.

Another important feature is the actuator type, as it determines the responsiveness and control precision of the valve. Pneumatic and electric actuators have distinct advantages; pneumatic actuators typically offer faster operation times, while electric actuators provide better precision and energy efficiency. A study from the Global Valve Automation Market Analysis indicates that systems equipped with electric actuators are projected to increase market share by 10% annually, highlighting a significant trend towards automation solutions that enhance operational accuracy. Additionally, firms should consider the valve size and flow coefficient (Cv), as these factors affect the system's overall efficiency and performance, ensuring that the selected valve meets the specific requirements of the application.

Impact of Automatic Valves on Efficiency and Safety

Automatic valves have become essential components in industrial applications due to their significant impact on operational efficiency and safety. By utilizing automated systems, industries can achieve greater precision in controlling fluid flow, which reduces the risk of human error that often occurs with manual operation. These valves can open and close at predetermined intervals or in response to specific pressure levels, ensuring that processes run smoothly and without interruption. This enhanced control translates into optimized production schedules, minimized downtime, and reduced energy consumption, ultimately leading to lower operational costs.

In terms of safety, automatic valves contribute to creating a secure working environment. They are equipped with advanced sensors and monitoring technologies that can detect anomalies in system pressure or flow, allowing for immediate corrective actions to prevent potential hazards. By automating critical shut-off and regulating functions, these valves eliminate the reliance on personnel, thereby decreasing the likelihood of accidents caused by human oversight. This proactive approach to safety not only protects workers but also safeguards equipment and the surrounding environment from potential damage. Overall, the integration of automatic valves into industrial systems is a strategic move that significantly enhances both efficiency and safety.

Maintenance and Reliability of Automatic Valves in Operations

Automatic valves play a crucial role in enhancing the maintenance and reliability of industrial operations. According to a report by the International Society of Automation, improper valve maintenance can lead to a staggering 20-30% of industrial process failures. By integrating automatic valves, industries can minimize human error and ensure consistent operations, significantly reducing unplanned downtimes. These valves are designed to operate seamlessly under varying conditions, which allows for efficient control over fluid flow without compromising system integrity.

Maintenance of automatic valves is further simplified through advanced monitoring and diagnostic technologies. Research from the American Society of Mechanical Engineers indicates that predictive maintenance can reduce maintenance costs by up to 30% by enabling timely interventions before failures occur. Automatic valves often come integrated with smart sensors that can alert operators to potential issues before they escalate, allowing for quick corrective actions and maintaining system performance. Consequently, industries that adopt automatic valves can expect improved reliability and operational efficiency, leading to significant cost savings and enhanced productivity.

Efficiency and Reliability of Automatic Valves in Industrial Applications

Related Posts

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Top Tips for Choosing and Maintaining Your Recirculation Valve

-

Top 10 Tips for Choosing the Best Valve Suppliers for Your Projects

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

10 Essential Tips for Locating and Operating Your Natural Gas Shut Off Valve

-

Top 5 Home Valve Solutions to Improve Your Plumbing Efficiency