Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

In today's industrial landscape, enhancing system efficiency and performance is paramount, particularly in fluid handling systems. Automatic recirculation valves (ARVs) play a critical role in achieving these objectives by ensuring optimal flow conditions and preventing issues such as cavitation and pump damage. According to a recent report by the Global Market Insights, the automatic recirculation valves market is projected to grow at a CAGR of 6.5% over the next five years, reflecting the increasing demand for reliable fluid management solutions across various sectors, including oil and gas, water treatment, and HVAC systems. By automatically adjusting the recirculation flow to maintain the desired operational parameters, ARVs help to significantly reduce energy consumption, thereby enhancing overall system performance. As industries continue to seek advancements in efficiency, understanding the capabilities of automatic recirculation valves becomes essential for leveraging their benefits in modern applications.

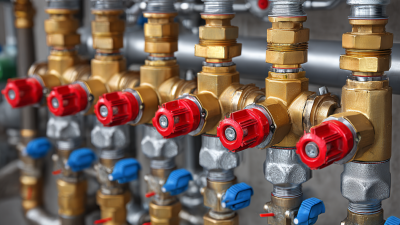

Benefits of Automatic Recirculation Valves in Fluid Systems

Automatic recirculation valves (ARVs) are essential components in fluid systems that significantly enhance efficiency and performance. By enabling continuous flow while maintaining optimal pressure, ARVs prevent issues like cavitation and dry running in pumps. According to industry reports, systems equipped with ARVs can see a reduction in energy consumption by up to 20%, leading to substantial cost savings for large-scale operations. This is particularly beneficial for industries like petrochemicals, where companies are investing heavily in infrastructure to increase production capacity.

Automatic recirculation valves (ARVs) are essential components in fluid systems that significantly enhance efficiency and performance. By enabling continuous flow while maintaining optimal pressure, ARVs prevent issues like cavitation and dry running in pumps. According to industry reports, systems equipped with ARVs can see a reduction in energy consumption by up to 20%, leading to substantial cost savings for large-scale operations. This is particularly beneficial for industries like petrochemicals, where companies are investing heavily in infrastructure to increase production capacity.

For companies such as those in the petrochemical sector, which are undertaking large projects like expanding production facilities, the incorporation of ARVs can streamline operations. In South Africa, substantial investments in production enhancements, such as doubling hard wax output, underline the importance of efficient fluid management systems. By automating the recirculation process, companies can ensure a consistent supply of fluid, reducing downtime and maintenance costs associated with pump failures.

Tips: When integrating ARVs into your fluid systems, consider conducting a flow analysis to accurately determine the optimal sizing for your system's needs. Regular maintenance checks on these valves can help ensure they operate effectively, prolonging the life of your pumps and enhancing overall system reliability.

Principles of Operation: How Automatic Recirculation Valves Function

Automatic recirculation valves (ARVs) play a crucial role in enhancing system efficiency and performance by maintaining optimal flow conditions in various applications. These valves operate based on a straightforward principle: they automatically divert a portion of the flow back to the inlet side of the pump when the system flow drops below a certain threshold. This not only prevents cavitation, a phenomenon that can cause significant damage to pumps, but also ensures that the system operates within its designed parameters. According to a report from the Hydraulic Institute, systems with properly installed ARVs can achieve energy savings of up to 20%, making them an essential component in energy-efficient designs.

In terms of technical operation, ARVs are usually equipped with a differential pressure mechanism that senses variations in flow. When flow conditions change, the valve adjusts itself accordingly, maintaining a consistent circulation rate even under fluctuating demands. This is particularly beneficial in systems where variable loads are common, such as in cooling and heating applications. Data from industry analyses indicate that integrating ARVs can significantly reduce wear and tear on equipment, thereby extending service life and decreasing maintenance costs. Overall, understanding the principles of operation behind automatic recirculation valves underscores their importance in optimizing system efficiency and ensuring reliable performance.

Optimizing Energy Efficiency with Proper Valve Sizing and Placement

Automatic recirculation valves (ARVs) play a crucial role in optimizing energy efficiency within various systems, particularly in industrial and HVAC applications. Proper valve sizing is vital; according to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), correctly sized valves can reduce energy consumption by up to 20% by minimizing pressure drops and ensuring adequate flow rates. An ideal ARV setup allows for the efficient circulation of fluids, which helps maintain consistent temperature and pressure throughout the system.

In addition to sizing, strategic placement of ARVs is essential to maximize system performance. A report by the Hydraulic Institute indicates that improper placement can lead to significant losses in flow and energy efficiency, as misaligned valves may cause turbulence and cavitation. When installed correctly, ARVs facilitate smooth flow transitions and enhance overall system reliability. By analyzing system requirements and conducting fluid dynamics simulations, engineers can identify optimal valve locations, ultimately leading to a more sustainable and cost-effective system operation.

Impact of Valve Sizing on Energy Efficiency

This chart illustrates the relationship between the proper sizing of automatic recirculation valves and the overall energy efficiency of a system. As valve size is optimized, energy consumption decreases significantly, leading to better system performance.

Common Applications of Automatic Recirculation Valves in Industry

Automatic recirculation valves (ARVs) play a crucial role in various industrial applications, enhancing system efficiency and operational performance. These valves are commonly used in boiler systems, where they maintain the necessary flow rates and prevent overheating by ensuring that a portion of the fluid is recirculated back into the system. This capability not only protects equipment but also contributes to energy savings, making it an essential component in the management of steam and hot water systems.

Tips: When selecting an automatic recirculation valve for your application, consider factors like the ambient conditions and fluid characteristics. Ensure that the valve's materials are compatible with the media being transported. Regular maintenance can also prolong the life of the valve, enhancing overall system performance.

Maintaining and Troubleshooting Automatic Recirculation Valve Systems

Automatic recirculation valves (ARVs) play a crucial role in maintaining system efficiency by ensuring adequate flow and pressure stability within industrial processes. However, like any mechanical component, these valves require routine maintenance and troubleshooting to operate at peak performance. According to a report by the American Society of Mechanical Engineers (ASME), regular inspections can prevent up to 30% of system failures by identifying early signs of wear and tear. Proper maintenance routines should include checking for leaks, ensuring the valve's response time is optimal, and verifying that the pressure settings are correctly calibrated.

Troubleshooting ARV systems often involves diagnosing issues related to flow control and preventing cavitation, which can lead to system malfunctions. A study conducted by the Hydraulic Institute indicated that up to 40% of pump failures can be traced back to improper valve operation. To effectively troubleshoot, technicians should monitor the valve’s performance metrics, such as pressure differentials and flow rates, using advanced diagnostic tools. By addressing these potential issues promptly, organizations can not only enhance the performance of ARVs but also extend their lifecycle, ultimately improving overall system efficiency.

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance - Maintaining and Troubleshooting Automatic Recirculation Valve Systems

| Dimension | Description | Impact on Efficiency | Common Issues | Maintenance Checklist |

|---|---|---|---|---|

| Flow Rate | Amount of fluid passing through the valve | Optimizes system performance by ensuring adequate flow | Inconsistent flow, blockage | Check for obstructions and measure flow rates |

| Pressure Differential | Difference in pressure across the valve | Indicates valve health and operational efficiency | Pressure drop or leakage | Monitor pressure readings regularly |

| Temperature Effects | The heat levels of the fluids handled | Affects material integrity and flow efficiency | Overheating, thermal expansion | Inspect for material degradation and thermal shock |

| Valve Position | Open or closed state of the valve | Directly influences flow and operational reliability | Sticking or malfunctioning mechanisms | Regularly test actuator function and position sensing |

Related Posts

-

Understanding the Importance of Shut Off Valves in Home Plumbing Systems: A Comprehensive Guide

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide