2026 Top Valve Products for Industrial Applications and Innovations?

As we approach 2026, the industrial landscape continues to evolve. Innovations in valve products are pivotal in shaping efficiencies across various sectors. These products play a crucial role in fluid control systems. They ensure safety, performance, and sustainability.

Current trends indicate a strong focus on advanced materials and technologies. New valve products offer improved durability and functionality. Smart valves equipped with IoT capabilities are emerging. These innovations facilitate real-time monitoring and adjustments. However, challenges persist. Not every industry is quick to adopt these advancements. Cost considerations and existing infrastructure can hinder implementation.

Effective valve products must address both immediate and long-term needs. Industries must assess their requirements and the potential benefits of new technologies. While innovation is essential, not every solution is perfect. Continuous evaluation and adaptation are necessary to harness the true potential of valve products in industrial applications.

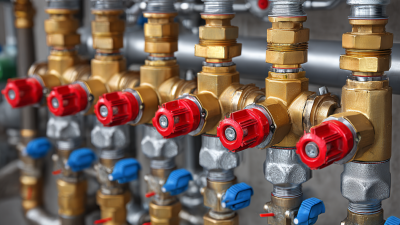

Overview of Industrial Valve Types and Their Applications

Industrial valves play a critical role in managing fluid flow in various applications. There are several valve types to consider. Gate valves, for example, are ideal for on/off control. They offer minimal resistance when fully open. However, they are not suitable for throttling.

Ball valves provide a reliable solution for tight sealing. They operate quickly, making them popular in many sectors. Butterfly valves are lightweight and compact. They work well in large pipelines where space is limited. Yet, their flow control can be less precise compared to other types.

One must also consider the environment where these valves operate. Corrosive materials may require special coatings. Thermal expansion can cause issues in high-temperature applications. Each valve type has its benefits and drawbacks. Understanding these nuances is vital for effective application. Choosing the right valve can sometimes be challenging. Reflecting on these aspects ensures better decision-making in industrial settings.

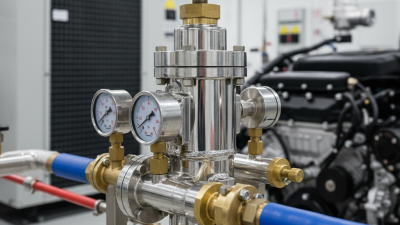

Key Innovations in Valve Technology for 2026

In 2026, valve technology is set to transform industrial applications significantly. Advanced materials and coatings are enhancing durability and performance. New designs optimize flow control, which is crucial in various sectors. Additionally, electro-pneumatic actuators are gaining traction. These can improve response times for critical processes.

Tips: Consider the environment when selecting valve materials. Corrosion resistance can prolong lifespan. Regular maintenance checks are essential. They can help identify potential issues early.

The integration of IoT and smart technology is another shift. Predictive analytics enables proactive rather than reactive maintenance. With real-time data, companies can optimize operations and minimize downtime. However, implementation can be challenging. Staff may need extensive training. Moreover, initial costs can be high, raising questions about budget allocation.

Tips: Start small with pilot projects. This approach can reduce risks and identify best practices. Collaborating with tech experts can also smooth the transition. Define clear goals to measure success effectively.

Market Trends Influencing Valve Product Development

The valve industry is experiencing notable shifts due to emerging market trends. One significant influence is the growing demand for automation in industrial applications. Companies seek smart valves that integrate seamlessly with IoT systems. This shift promotes efficiency and real-time data tracking, essential for modern production lines.

Another trend is sustainability. More manufacturers focus on eco-friendly materials and energy-efficient designs. The pressure to reduce carbon footprints is compelling companies to innovate. However, achieving these goals can be challenging. Balancing performance with eco-friendliness requires thoughtful consideration. There are questions about material longevity and recyclability that need exploration.

Moreover, the focus on safety and regulations continues to evolve. Industries must comply with stricter standards. This places pressure on valve manufacturers to create safer, more reliable products. As regulations tighten, the development process becomes more complex. Innovating in this environment can lead to breakthroughs but also potential setbacks. It’s a continual cycle of learning and adapting in an ever-changing landscape.

Sustainability and Eco-Friendly Innovations in Valve Design

The shift toward sustainability in valve design is vital. Industry reports show that eco-friendly materials can reduce carbon footprints significantly. For instance, using recycled metals and biopolymers in valve construction decreases energy consumption during manufacturing. This transition can lead to a 30% reduction in overall emissions.

However, challenges persist. Many manufacturers hesitate to adopt these materials due to higher initial costs. Long-term benefits often outweigh these expenses, but investment remains a hurdle. A significant percentage of companies still prioritize immediate profits over sustainability.

Innovative designs feature energy-efficient mechanisms. Smart valves equipped with IoT technology monitor performance. This minimizes leaks and conserves resources. Yet, the adaptation of such advanced technologies can face resistance from traditional sectors. The path to sustainable valve products is complex, requiring collaboration across the industry. Such cooperation is essential for a greener future and can lead to breakthrough innovations in the coming years.

2026 Top Valve Products for Industrial Applications and Innovations

This chart illustrates the projected market growth of eco-friendly and sustainable valve products in industrial applications over the next few years, highlighting the increasing demand for innovative designs.

Future Challenges and Opportunities in the Industrial Valve Sector

The industrial valve sector faces numerous challenges as it navigates into the future. With the rise of automation and IoT, industries must adapt their valve technologies. This requires a keen focus on interoperability and real-time data integration. A gap still exists in seamless communication between devices. Many companies struggle with outdated systems that can't keep up with modern demands.

There are also opportunities within sustainability. Many sectors are pushing for eco-friendly materials and energy-efficient designs. Innovating in these areas can help reduce energy consumption. However, the push for greener solutions often clashes with cost concerns. Striking a balance is not straightforward. Additionally, the knowledge gap in new valve technologies can hinder progress. Training and development are crucial yet often overlooked.

The shift toward digitalization presents both risks and rewards. Cybersecurity is a growing concern. With systems becoming more interconnected, the potential for breaches increases. Companies need to invest in robust security measures. At the same time, they must innovate to stay competitive. It’s a tightrope walk between embracing technology and securing it. The future of the industrial valve sector will require both bold innovations and cautious strategies.

Related Posts

-

Top 10 Tips for Choosing the Best Valve Suppliers for Your Projects

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

How to Choose the Right Saunders Valves for Your Applications

-

Top 10 Valve Home Innovations to Watch in 2025

-

How to Choose the Right Valve for Your Plumbing Needs?

-

Top 10 Benefits of Recirculation Valve for Efficient Performance