2026 Best Gas Valves for Optimal Performance and Safety?

Gas valves play a crucial role in ensuring optimal performance and safety for various systems. As industry expert John Talbot emphasizes, “Choosing the right gas valve can make all the difference in safety.” Understanding their importance is essential.

In a world increasingly dependent on natural gas, the need for reliable gas valves is paramount. They regulate the flow of gas, ensuring efficient operation in homes and industries. However, not all gas valves are created equal. Some may fail under pressure, causing dangerous situations. This reality emphasizes the importance of selecting the best models available.

It’s essential to recognize the fine line between safety and risk when it comes to gas valves. Each valve must be evaluated based on its design, materials, and manufacturer reputation. Mistakes can lead to significant consequences, making informed choices vital. Finding the best gas valves is not merely about function; it's about safeguarding lives.

Understanding Gas Valves: Types and Their Functions

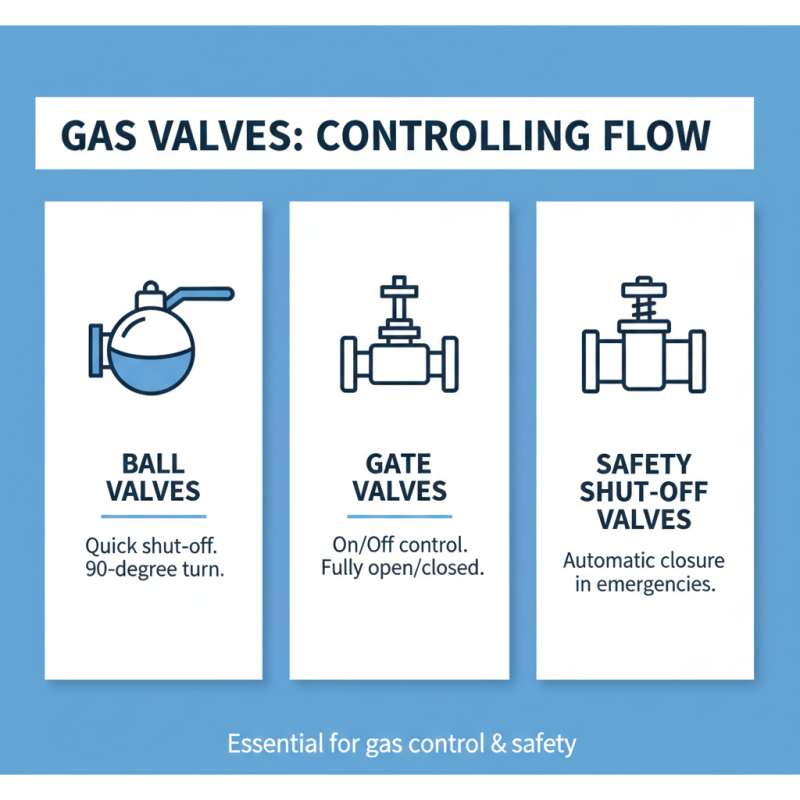

Gas valves play a crucial role in controlling the flow of gas in various applications. They come in different types, each serving its own function. The most common types include ball valves, gate valves, and safety shut-off valves. Ball valves offer quick shut-off capabilities, while gate valves are intended for on/off control in a fully open or closed position. Safety shut-off valves are designed to automatically close in emergencies.

Understanding the specific function of each valve type is essential. For instance, ball valves can easily be used in high-pressure systems. Their simple design allows for efficient flow and minimal pressure drop. On the other hand, safety shut-off valves are vital for ensuring safety. They prevent leaks and potential hazards. When installing gas valves, attention to detail is necessary. Mistakes can lead to severe consequences, emphasizing the importance of proper installation.

Choosing the right gas valve involves considering the application and safety requirements. Not every valve fits every system. This journey requires thought and sometimes trial and error. Manufacturers may vary in their specifications, leading to confusion. It's a challenging task to know which one to trust. Regular maintenance is needed to ensure optimal performance. Neglect can result in failures, highlighting the delicate balance required in managing gas systems.

Key Features to Look for in Gas Valves for Optimal Performance

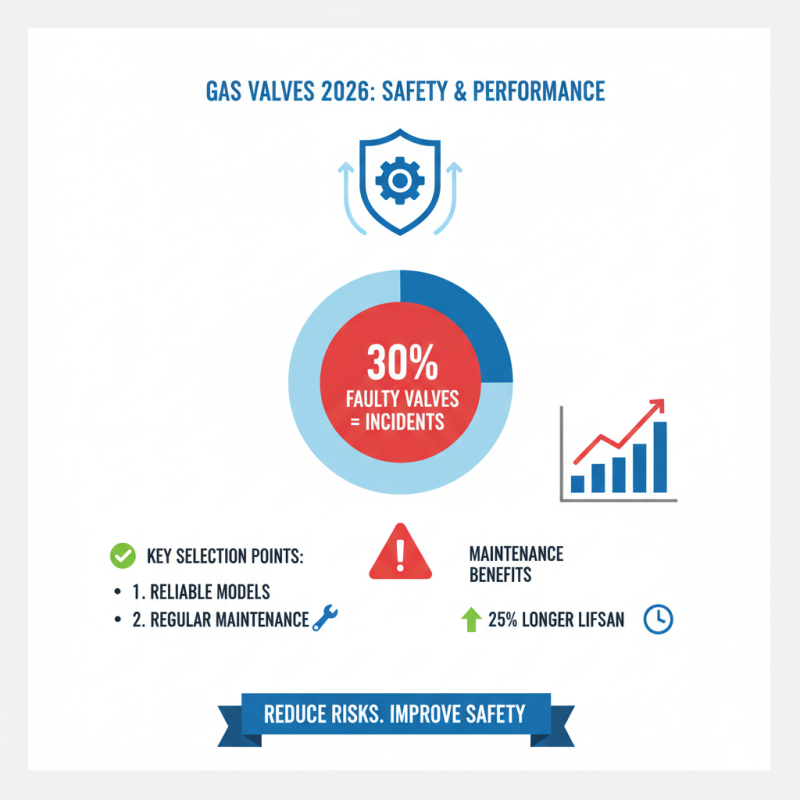

When considering gas valves for optimal performance, several key features stand out. One crucial factor is the valve's flow control capability. High-quality gas valves can maintain consistent flow rates. Inconsistent flow can lead to operational issues. The American Gas Association reports that nearly 30% of gas-related failures are due to flow irregularities.

Another important aspect is the material used in the valve's construction. Valves made from robust materials like brass or stainless steel tend to have longer lifespans. According to industry studies, valves made from these materials last up to 50% longer than their plastic counterparts. Yet, many users opt for cheaper alternatives, risking premature failure.

Safety mechanisms are vital as well. Look for valves with automatic shut-off features. These enhance safety significantly, reducing the chances of leaks. A report from the National Fire Protection Association highlights that improper valve operations contribute to over 20% of gas-related incidents. However, many overlook this feature in their selection process. This oversight can lead to severe consequences in the long run.

Safety Standards and Regulations for Gas Valve Selection

When selecting gas valves, safety standards and regulations are paramount. Different regions have unique requirements. It's crucial to familiarize yourself with local codes to ensure compliance. This lowers risks and enhances safety.

Tips: Always check regulations before installation. Consult with local authorities for updates. Ignoring this can lead to unsafe conditions.

Choosing the right gas valve is not just about performance; it’s about securing your environment. Valves must meet specific safety certifications. Look for indicators that reflect these standards. This helps ensure optimal functionality over time.

Tips: Regular maintenance is essential. Inspect valves periodically for wear. Address issues immediately to prevent potential hazards. Balancing performance with safety is a challenge that requires ongoing attention.

Installation and Maintenance Best Practices for Gas Valves

When installing gas valves, attention to detail is crucial. Proper installation is vital for safety and performance. According to the American Society of Mechanical Engineers, improper installation can lead to leaks. These leaks pose significant risks, including potential explosions. Ensuring a tight seal is fundamental. Some experts suggest using Pipe Joint Compound to enhance sealing.

Regular maintenance also plays a key role in gas valve longevity. Routine inspections can reveal wear or corrosion before they escalate. The National Fire Protection Association recommends checking valves at least twice a year. Small issues can turn into major hazards if overlooked. Keeping valves clean and free from debris is essential.

Training staff about installations and maintenance cannot be ignored. Lack of knowledge can lead to mistakes. Industry reports show that 30% of gas-related incidents arise from human error. Continuous education can mitigate these risks. Additionally, documenting maintenance activities helps track valve performance over time, building accountability.

Top Brands and Models of Gas Valves for 2026: A Comparison Guide

When selecting gas valves for 2026, safety and performance are crucial. Many industry reports indicate that around 30% of gas-related incidents stem from faulty valves. Choosing the right model can significantly reduce risks. A study showed that regular maintenance can enhance valve lifespan by 25%.

Tip: Always check for certifications. Valves must comply with safety standards. Installing a valve without certification can invite failures.

Consider features like pressure rating and material. Some models offer corrosion resistance, extending their use in harsh environments. Misjudging material selection can lead to leaks. Reports show improper installations can increase repair costs by 40%.

Tip: Look for user reviews. Feedback provides insight into real-world performance. Often, specifications look good on paper, but experiences vary. This helps in making an informed choice.

Related Posts

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

How to Choose the Right Gas Valves for Your Home or Business Needs

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

Top Gas Valves: Essential Types, Uses, and Buying Guide

-

Top 10 Valve Home Innovations to Watch in 2025

-

2025 How to Choose the Best Valve Products for Your Industry Needs